You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Okay, TUNERS AGAIN. Bukys/Schmidt style versus Beggs???????????????

- Thread starter CYanchycki

- Start date

This is mostly cut-and-paste from an email to Calvin... figured I could share it with the rest of you too. Calvin was asking about my decals and how I find a pet load. (It was a private email so don't take anything as a slight against any individuals. I have learned a bunch from the folks on this site and can't thank Gene Begg's enough for his insights that started me down this path.)

=================

I built the decals to match the thread pitch on the tuners. For my Beggs tuner, it turns out that 28 threads per inch is .0357 per revolution, so I built a decal with 36 marks (every 10 degrees). I built my own tuners for the rail gun, but on 32tpi… 1/32 = .03125 per revolution. I rounded that to 30 marks (every 12 degrees) for that decal. Either scale can then be read as approximately .001 inches of movement per mark on the decal. There is a little error (.0003 on the LV and .000125 on the rail) but it doesn’t matter, because the numbers are only used relative to their own scale. Having it in thousandths was convenient for other calculations on bullet exit time, etc.

Gene has his own ideas on how these work, but his thoughts are based on his experiments in the tunnel. I believe his notion of a single mark, and tuning by moving a quarter turn is simply too coarse of an adjustment – sort of like only moving your powder measure whole numbers. It can work, but the result is that you accept some small amount of vertical in the groups. I try to tune every group as absolutely flat as I can make it… that’s where being able to take notes .001 makes a difference.

On flat groups: Tony’s book and guys like Jackie S. recommend that a little vertical is OK or even desired. It is, if you can’t if can’t adjust at the bench. But trigonometry says the hypotenuse of a triangle is always longer than the legs, so a group with vertical and horizontal will ALWAYS be bigger than a group with just horizontal. Understanding that fact alone pushed my aggs from always above .3 to regularly in the .2s and occasionally in the .1s. You cannot consistently shoot .2 aggs without managing the vertical in your groups. Even though those guys accept a little vertical, they are tuning VERY carefully with the powder measure and seating depth to keep it small. I just leave the load the same and work to accomplish repeatable results with a tuner. Which is why I don’t buy the argument that a tuner is “one more thing” to keep track of… it actually make 2 less since I never have to mess with the load!

Establishing a good load is mostly just old-fashioned trial and error with a plan. This method is generally described as the “ladder test”.

1. Start with readable conditions – it doesn’t have to be calm, but if you can’t call the shots, save your powder.

2. For all the test groups, do NOT hold off… let the wind carry the bullets, you are looking for dispersion patterns, not “small” groups.

3. Only change one variable at a time.

4. I screw the tuner to a reference-able position (all the way to the shoulder, then out 1 full turn, and then a little more until my “0” is on top. Leave it there until you find a load that works.

5. Pick a powder and try loads from light (about 27.7) to heavy (29.3 or so) in about .2 or .3 grain increments. The groups will get big and small and big and small as you progress through the nodes. Watch for a sequence of groups within a node that still all cluster around a similar point of impact… it may not be that smallest set of groups, but it is the most forgiving node for that barrel.

6. If you want you can try fine tuning the seating depth. I usually skip this and go straight to my tuner unless that barrel just isn’t shooting anything small. If so, pick the “center” of the powder charge for the best node and shoot groups at jam, +.005, +.010, +.015, and so on to about +.030. Again, watch for a sequence of groups that cluster around the same impact point. A single .0 group that forms at 3 o’clock when all your other groups are .2s at 6 o’clock is just a teaser that will bite you if you try to use it. Focus on finding a load that is reliable and forgiving – because that is “standard” for what that barrel is actually capable of agging – not the anomalies.

7. Now you can note your load, conditions (temp/humidity/wind), and tuner position as decent starting point.

When I started this, I was tuning my load for a particular reference point on the tuner and it was about 65 degree F outside. When a match started at 50 degrees, I noticed that I had to move the tuner back toward the bolt about 12-18 marks (.001s of an inch) to get the same group size. As the day warmed up, I just kept moving the tuner out (toward the muzzle) a little to keep shooting my “standard” size groups. I usually end up testing 2, 3, or 4 groups on the sighter before I settle on a tuner setting for that target. I got into the analysis once I noticed I was agging significantly better than my past performance.

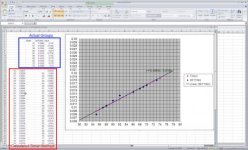

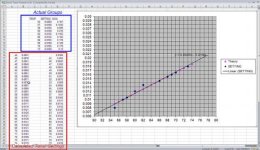

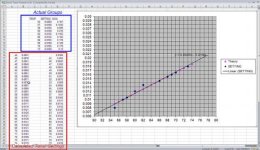

(Click on the attachment link below) In the chart below are some results from a 5-shot railgun shoot (first 5 targets at 200y, next at 100y). The aggs were .144 and .155, so it was a very good day for analyzing the results. The “Setting” refers to the mark on the tuner decal when the group was shot. The blue dots on the graph looked linear to me, so I had Excel calculate the “best fit” linear formula => y=.0005x + some offset. The offset doesn’t matter, the key was that .0005 number. It was one-half a mark on my decal per degree of temperature change that produced a nearly perfect match. The was further confirmed by the fact that the biggest groups are the ones that are farthest from the “correct” setting.

I have done several similar graphs on my bag gun and the result was nearly always the same … y = .0012x + some offset. The same number worked out for 3 different barrels on my LV gun, and all three have produced multiple teen aggs. My best guess about why it is different that the rail gun lies in the two obvious factors: barrel length and barrel profile. I do have two sets of tuners for the rail gun, one that is twice the weight of the other. Both sets seem to correlate to the .0005 factor, but I have not shot the lighter one enough to definitively say that tuner weight is or is not a factor. My gut feel is that it is not.

CAVEAT 1: this chart only correlates temperature, the humidity was fairly constant that day (+/- 20%) or so.

CAVEAT 2: the “offset” changes depending on range elevation, “average” humidity, etc., so you can’t just build a cheat sheet that works everywhere, all the time.

On humidity: unless it is changing drastically (5-10% or more between targets), ignore it. Move the tuner for the temp change, then shoot some test groups and fine-tune it. That said, I did have one very good day to test it, when I shot a teen agg and the temp stayed a constant 65 degrees, but the humidity dropped from 95% to 25% over 5 targets. I built a similar chart and found a formula of that indicated I needed to move the tuner about .001 per 10% of humidity change (increase in humidity => move tuner toward the muzzle, decrease=> toward the bolt). Usually, the humidity change from one target to the next is small enough that you can just ignore it, though I write it down for this kind of later analysis.

I think the key things to know about using a tuner are:

• Small adjustments can make a visible, repeatable difference. Big adjustments are node jumpers and are very hard to make any sense of. This is why Gene Beggs’ method of tuning is more like a random hunt for a node.

• The starting point may change a little, even on the same range at apparently similar conditions, but once you have an adjustment factor, it works pretty well across a fairly broad temperature range (say roughly 30-95F). Outside of that, the powders start behaving differently and you just have to experiment. I have been burned trying to make it work at 102 degree/98% in St Louis and at 25 degrees in Colorado.

This got very long-winded, but it covers most of I everything I know. I tried to keep this to the facts I’ve seen on my targets. A lot of folks will tell you that tuners don’t work or are too hard to use. I may burn more powder and use more bullets, but I’ll bet on my tuner against a powder measure any day!

=================

Rod Brown

(P.S. I can't seem to get this chart to show up any bigger... )

=================

I built the decals to match the thread pitch on the tuners. For my Beggs tuner, it turns out that 28 threads per inch is .0357 per revolution, so I built a decal with 36 marks (every 10 degrees). I built my own tuners for the rail gun, but on 32tpi… 1/32 = .03125 per revolution. I rounded that to 30 marks (every 12 degrees) for that decal. Either scale can then be read as approximately .001 inches of movement per mark on the decal. There is a little error (.0003 on the LV and .000125 on the rail) but it doesn’t matter, because the numbers are only used relative to their own scale. Having it in thousandths was convenient for other calculations on bullet exit time, etc.

Gene has his own ideas on how these work, but his thoughts are based on his experiments in the tunnel. I believe his notion of a single mark, and tuning by moving a quarter turn is simply too coarse of an adjustment – sort of like only moving your powder measure whole numbers. It can work, but the result is that you accept some small amount of vertical in the groups. I try to tune every group as absolutely flat as I can make it… that’s where being able to take notes .001 makes a difference.

On flat groups: Tony’s book and guys like Jackie S. recommend that a little vertical is OK or even desired. It is, if you can’t if can’t adjust at the bench. But trigonometry says the hypotenuse of a triangle is always longer than the legs, so a group with vertical and horizontal will ALWAYS be bigger than a group with just horizontal. Understanding that fact alone pushed my aggs from always above .3 to regularly in the .2s and occasionally in the .1s. You cannot consistently shoot .2 aggs without managing the vertical in your groups. Even though those guys accept a little vertical, they are tuning VERY carefully with the powder measure and seating depth to keep it small. I just leave the load the same and work to accomplish repeatable results with a tuner. Which is why I don’t buy the argument that a tuner is “one more thing” to keep track of… it actually make 2 less since I never have to mess with the load!

Establishing a good load is mostly just old-fashioned trial and error with a plan. This method is generally described as the “ladder test”.

1. Start with readable conditions – it doesn’t have to be calm, but if you can’t call the shots, save your powder.

2. For all the test groups, do NOT hold off… let the wind carry the bullets, you are looking for dispersion patterns, not “small” groups.

3. Only change one variable at a time.

4. I screw the tuner to a reference-able position (all the way to the shoulder, then out 1 full turn, and then a little more until my “0” is on top. Leave it there until you find a load that works.

5. Pick a powder and try loads from light (about 27.7) to heavy (29.3 or so) in about .2 or .3 grain increments. The groups will get big and small and big and small as you progress through the nodes. Watch for a sequence of groups within a node that still all cluster around a similar point of impact… it may not be that smallest set of groups, but it is the most forgiving node for that barrel.

6. If you want you can try fine tuning the seating depth. I usually skip this and go straight to my tuner unless that barrel just isn’t shooting anything small. If so, pick the “center” of the powder charge for the best node and shoot groups at jam, +.005, +.010, +.015, and so on to about +.030. Again, watch for a sequence of groups that cluster around the same impact point. A single .0 group that forms at 3 o’clock when all your other groups are .2s at 6 o’clock is just a teaser that will bite you if you try to use it. Focus on finding a load that is reliable and forgiving – because that is “standard” for what that barrel is actually capable of agging – not the anomalies.

7. Now you can note your load, conditions (temp/humidity/wind), and tuner position as decent starting point.

When I started this, I was tuning my load for a particular reference point on the tuner and it was about 65 degree F outside. When a match started at 50 degrees, I noticed that I had to move the tuner back toward the bolt about 12-18 marks (.001s of an inch) to get the same group size. As the day warmed up, I just kept moving the tuner out (toward the muzzle) a little to keep shooting my “standard” size groups. I usually end up testing 2, 3, or 4 groups on the sighter before I settle on a tuner setting for that target. I got into the analysis once I noticed I was agging significantly better than my past performance.

(Click on the attachment link below) In the chart below are some results from a 5-shot railgun shoot (first 5 targets at 200y, next at 100y). The aggs were .144 and .155, so it was a very good day for analyzing the results. The “Setting” refers to the mark on the tuner decal when the group was shot. The blue dots on the graph looked linear to me, so I had Excel calculate the “best fit” linear formula => y=.0005x + some offset. The offset doesn’t matter, the key was that .0005 number. It was one-half a mark on my decal per degree of temperature change that produced a nearly perfect match. The was further confirmed by the fact that the biggest groups are the ones that are farthest from the “correct” setting.

I have done several similar graphs on my bag gun and the result was nearly always the same … y = .0012x + some offset. The same number worked out for 3 different barrels on my LV gun, and all three have produced multiple teen aggs. My best guess about why it is different that the rail gun lies in the two obvious factors: barrel length and barrel profile. I do have two sets of tuners for the rail gun, one that is twice the weight of the other. Both sets seem to correlate to the .0005 factor, but I have not shot the lighter one enough to definitively say that tuner weight is or is not a factor. My gut feel is that it is not.

CAVEAT 1: this chart only correlates temperature, the humidity was fairly constant that day (+/- 20%) or so.

CAVEAT 2: the “offset” changes depending on range elevation, “average” humidity, etc., so you can’t just build a cheat sheet that works everywhere, all the time.

On humidity: unless it is changing drastically (5-10% or more between targets), ignore it. Move the tuner for the temp change, then shoot some test groups and fine-tune it. That said, I did have one very good day to test it, when I shot a teen agg and the temp stayed a constant 65 degrees, but the humidity dropped from 95% to 25% over 5 targets. I built a similar chart and found a formula of that indicated I needed to move the tuner about .001 per 10% of humidity change (increase in humidity => move tuner toward the muzzle, decrease=> toward the bolt). Usually, the humidity change from one target to the next is small enough that you can just ignore it, though I write it down for this kind of later analysis.

I think the key things to know about using a tuner are:

• Small adjustments can make a visible, repeatable difference. Big adjustments are node jumpers and are very hard to make any sense of. This is why Gene Beggs’ method of tuning is more like a random hunt for a node.

• The starting point may change a little, even on the same range at apparently similar conditions, but once you have an adjustment factor, it works pretty well across a fairly broad temperature range (say roughly 30-95F). Outside of that, the powders start behaving differently and you just have to experiment. I have been burned trying to make it work at 102 degree/98% in St Louis and at 25 degrees in Colorado.

This got very long-winded, but it covers most of I everything I know. I tried to keep this to the facts I’ve seen on my targets. A lot of folks will tell you that tuners don’t work or are too hard to use. I may burn more powder and use more bullets, but I’ll bet on my tuner against a powder measure any day!

=================

Rod Brown

(P.S. I can't seem to get this chart to show up any bigger... )

Attachments

Last edited:

Anyone who's interested in tuning mechanically and who doesn't print off Rod's posts is missing the boat. I'm not saying any one way is 'best' because I'm completely tuner inept (altho I have twenty of them, some twenty yrs old) but if nothing else they'll provide DAYS of brainbanging, and they definitely "do something!"

I quit with the tuners about the time I set my Juenke aside and have tried to learn to steenking SHOOT for the last few years but thanks to Gene and tim and Lynn and Calfee and Borden and Butch Lambert et al..... and now Rod Brown..... I've got ten barrels threaded up.

A'gain,

FAS'kinating.....

Y'all make Wilbur look good

al

I quit with the tuners about the time I set my Juenke aside and have tried to learn to steenking SHOOT for the last few years but thanks to Gene and tim and Lynn and Calfee and Borden and Butch Lambert et al..... and now Rod Brown..... I've got ten barrels threaded up.

A'gain,

FAS'kinating.....

Y'all make Wilbur look good

al

jackie schmidt

New member

Revisionist History

I will let all of you speculate on what I was going to say.........jackie

I will let all of you speculate on what I was going to say.........jackie

CYanchycki

Club Coordinator

SUPER Cub Couper if I can call you that Rodney..... LOL

Could you clarify this statement you made in your earlier post.

Temp goes up a degree, I move my tuner out by 1.2 marks based on the decal I put on my tuner.

Looking at the image of your tuner I do not get the 1.2 per degree increase in temp?????

Calvin

Could you clarify this statement you made in your earlier post.

Temp goes up a degree, I move my tuner out by 1.2 marks based on the decal I put on my tuner.

Looking at the image of your tuner I do not get the 1.2 per degree increase in temp?????

Calvin

I will let all of you speculate on what I was going to say.........jackie

C'mon Jackie, don't be coy, spit it out.

"and over"

We all only live in our own minds and (failing) memories......you're a real player here. I for one want to learn something. If nothing else it's still winter somewheres........

al

CYanchycki

Club Coordinator

Anyone who's interested in tuning mechanically and who doesn't print off Rod's posts is missing the boat.

My thoughts exactly AL. Just another man's thoughts on what he does and what works for him. I say he has gone out on a limb to share this with the masses whether or not the different camps believe it or not.

Ah yes the different tuner camps........... Begg's, Bukys/Schmidt, Calfee, heavy tuner, heavy tuner not required. Wow 5 can you say 5 different tuner camps. Oh but in amongst these camps individuals who have found ways of tweaking and finding what has and is working for them.

Yep just like a kid in a candy store.............. LOL

Calvin

A couple of other thoughts...

First, I only have experience with my Beggs (bag gun) and Beggs-style (rail gun) tuners. It would be interesting to see if the results were the same for other styles (different weights, past the muzzle, etc.)

Second, the groups in the chart above were the very first match I shot with that rail gun ever... used rail but new action, new barrel, tuner hot off the lathe. Sometimes I find myself trying to force a calculated setting rather than following "my method"... the more I do that, the more I influence my own results. But in the rail gun case above, that was was not case -- I had no reference to start from.

Third, nothing seems to make as much difference as having good barrels. I was very lucky to have 4 exceptional barrels to work this stuff out. Those barrels still shoot awesome even without a tuner. My latest barrel absolutely proved that a tuner cannot make a shooter out of a tomato stake. (I hope the next 2 are better ).

).

1.2 tick marks === 1 mark plus a little... so if the temp went from 65 to 67, I would move the rings from say 4 to 6-1/2.

Rod

First, I only have experience with my Beggs (bag gun) and Beggs-style (rail gun) tuners. It would be interesting to see if the results were the same for other styles (different weights, past the muzzle, etc.)

Second, the groups in the chart above were the very first match I shot with that rail gun ever... used rail but new action, new barrel, tuner hot off the lathe. Sometimes I find myself trying to force a calculated setting rather than following "my method"... the more I do that, the more I influence my own results. But in the rail gun case above, that was was not case -- I had no reference to start from.

Third, nothing seems to make as much difference as having good barrels. I was very lucky to have 4 exceptional barrels to work this stuff out. Those barrels still shoot awesome even without a tuner. My latest barrel absolutely proved that a tuner cannot make a shooter out of a tomato stake. (I hope the next 2 are better

1.2 tick marks === 1 mark plus a little... so if the temp went from 65 to 67, I would move the rings from say 4 to 6-1/2.

Rod

Last edited:

Gene Beggs

Active member

Thanks Rod

Your scientific computer-aided approach to tuner operation puts me to shame. Thank you for all your hard work and for sharing the results with the rest of us. You may very well be right; maybe I DO make too course adjustments. I try to keep an open mind about everything and if your assessment of it all proves to be better than what I've been using, I'll be the first to admit it and publicly acknowledge you for setting me straight. It wouldn't be the first time I've been found wrong about something. I'll get out there in the tunnel and do some serious testing. Again, thanks so much for sharing what you have found through hard work with the rest of us. With people like you helping, we will eventually get to the bottom of all this.

Come on Jackie, let's hear what you have to say.

Oh,, by the way, Gene Bukys, you once said to me, "I was where you are three and a half years ago." That was about three and a half years ago. I'm slowly but surely coming up the road after ya'.

By the way folks, Gene Bukys is the big, ugly Gene B., with a grey beard who for the last two times running was and is World Benchrest Champion! Me? I'm the other Gene B, Gene Beggs, the shorter, fatter, clean shaven and much better looking Gene. Remember, Gene Bukys, the World Champion and Gene Beggs the one who is not.

Remember, Gene Bukys, the World Champion and Gene Beggs the one who is not.  Isn't this stuff fun?

Isn't this stuff fun?

Later,

Gene Beggs

The Wind Probe guy

Your scientific computer-aided approach to tuner operation puts me to shame. Thank you for all your hard work and for sharing the results with the rest of us. You may very well be right; maybe I DO make too course adjustments. I try to keep an open mind about everything and if your assessment of it all proves to be better than what I've been using, I'll be the first to admit it and publicly acknowledge you for setting me straight. It wouldn't be the first time I've been found wrong about something. I'll get out there in the tunnel and do some serious testing. Again, thanks so much for sharing what you have found through hard work with the rest of us. With people like you helping, we will eventually get to the bottom of all this.

Come on Jackie, let's hear what you have to say.

Oh,, by the way, Gene Bukys, you once said to me, "I was where you are three and a half years ago." That was about three and a half years ago. I'm slowly but surely coming up the road after ya'.

By the way folks, Gene Bukys is the big, ugly Gene B., with a grey beard who for the last two times running was and is World Benchrest Champion! Me? I'm the other Gene B, Gene Beggs, the shorter, fatter, clean shaven and much better looking Gene.

Later,

Gene Beggs

The Wind Probe guy

Thanks Gene B. It was that day in your tunnel that started this whole journey for me. Before that I was just "shooting in the dark", probably still am. The worst thing is that in my 4 moves in the last three years, I have misplaced all my match logbooks. I still have the targets, but not the notes that go with them. Time to start over.

Rod

Rod

Gene Beggs

Active member

Atta' boy Rod!

Thank goodness Rod! You had me worried and even doubting myself there for a little while because I knew I always had to go IN (toward the breach) as temp increased. Now, hopefully, I can get back to sleep. This stuff will mess with your mind; won't it? You're sure right about barrels; they trump everything else. Tony has been right all along; there are good barrels and then there are the 'tomato stakes' which I seem to have had more than my share of lately.

You're sure right about barrels; they trump everything else. Tony has been right all along; there are good barrels and then there are the 'tomato stakes' which I seem to have had more than my share of lately.

Keep up the good work and thanks for sharing.

Gene Beggs

BIG CORRECTION, Got my directions messed up. I said OUT, when I meant IN for temps that are increasing.... didn't notice that. Sorry.

(I'll edit the earlier posts!)

Rod

Thank goodness Rod! You had me worried and even doubting myself there for a little while because I knew I always had to go IN (toward the breach) as temp increased. Now, hopefully, I can get back to sleep. This stuff will mess with your mind; won't it?

Keep up the good work and thanks for sharing.

Gene Beggs

Gene Beggs

Active member

For all of the folks reading this who are not competitive BR Shooters I feel some clarification is in order.

The above posts, especially this last one by Mike Ezell make this sound easy. I can see folks lining up to buy "tuners" for their varmint rifles.

IT'S NOT

When Mike says "I can see a difference in half numbers" and "It comes on pretty fast" this is like a Formula One driver coming into the pit and telling his mechanic "she's a little loose in corner 6 over there, I think we should crank 'er up just a little on the inside and maybe increase downforce..." And when Mike sez ""reasonably good grasp.....less than 100rds" he's talking to BR Shooters.

This tuner stuff applies to BENCH REST RIFLES. Tuners aren't going to change the world of F-Class shooting... A tuner absolutely will not make your factory or hybrid rifle shoot dots, in fact in my opinion the effects of a tuner are hard to even see when used on a less than accurate rifle. They're also hard to see if you don't KNOW how to shoot, like KNOW where the bullet should have went.

I know, this IS the Benchrest Forum, but that doesn't keep people from making assumptions.

If this caution is inappropriate you guys let me know and I'll delete it.

I felt it hadda' be said

al

You are absolutely right Al. Very good point!

Thanks

Gene Beggs

jackie schmidt

New member

Rod makes a great point in post #70. A tuner will NOT turn an average barrel into a screamer. All it will do is allow you to find the best that barrel has to offer. Often that is still not good enough..............jackie

M

mks

Guest

BIG CORRECTION, Got my directions messed up. I said OUT, when I meant IN for temps that are increasing.... didn't notice that. Sorry.

(I'll edit the earlier posts!)

Rod

Whew, glad I didn't read your post before the correction. My mind would have been in a tizzy.

Thanks again for posting. Really nice work you have done.

From your description, it sounds like you do ladder testing with groups of shots in which all shots use the same powder charge, thus all have close to the same muzzle velocity and bullet exit time. I wonder if you have tried intentionally creating a range of muzzle velocities within a group by including in that group different powder charges. That way you are testing whether the tuner can compensate for the differences in bullet exit time, where the consequences on target have been made large enough that you can see them at 100 yards.

Cheers,

Keith

My load development doesn't follow the full-blown ladder testing treatment -- probably a topic for another thread.

I usually trust my gun enough to just calibrate the load by watching the vertical in the group. Loads that are on a node boundary seem blow up in every direction. If you subscribe to the shock wave theory, this would suggest the bullet is exiting while the pulse in at the muzzle. Between cusps, 3-5 shot groups have readable vertical dispersion (and it is quite possible to put two or three in one hole but have the fourth climb out by a bullet or two - that is why I usually shot a couple of 3-4 shot groups on my sighter before going to the record). I visualize the effect as trying to make an adjustment that will time the bullet exit a tiny touch earlier (screwing the tuner in or out by .001-.002" would make the pulse reflection times a tiny bit shorted or longer and re-position the pulse away from the muzzle as the bullet exits.

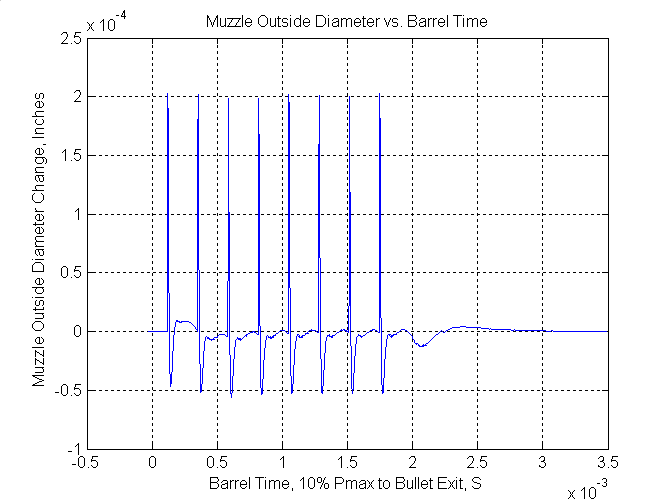

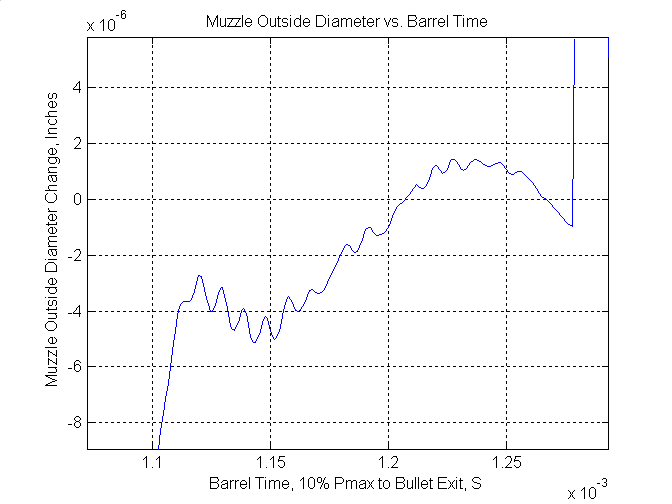

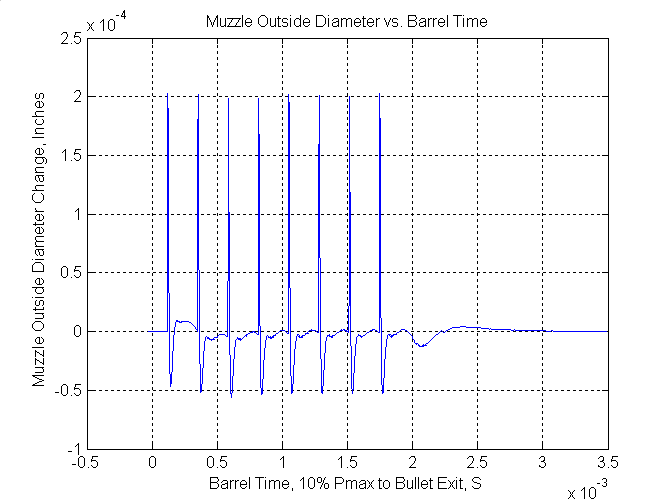

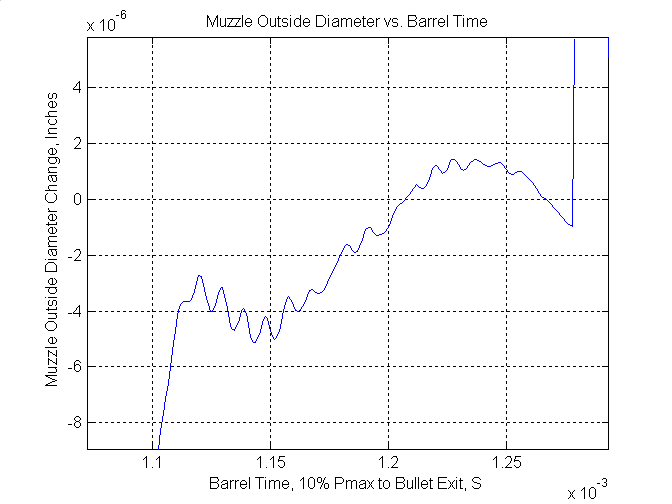

From Chris Long's paper, this graph is a model that plots bore diameter at the muzzle (choke, if you please) against the timing of an acoustic shock wave in steel. The spikes are points where the shock wave it at the muzzle and it is correspondingly "all over the place". By changing loads, a 6PPC bullet in a 21" barrel exits the barrel between .0007 and .0010 seconds -- about between the 3th and 5th spike, which might explain what we know as the low node and high node with the BIG group between them.

For tuning purposes, the more interesting graph is when you zoom in on the tiny sine-wave between the spikes. Here, the "sweet spots" are the bottom and top of the humps where there is a stable muzzle diameter for a longer period of time. A forgiving load makes those regions of time as wide as possible; tiny tweaks on the tuner let you center up on them each time you come to the bench. Note that it looks like the classic mode 1, ruler-on-the-desk sine wave that usually gets associated with barrel vibration, but in fact is behaving 10,000x faster than the mode-1 vibrations and is a muzzle-strain, not harmonic vibration.

My goal for the centerfire BR tuner is to micro-manage bullet exit time, not attempt to broaden the node by compensating for exit time (that would be the tune-for-dead-vibration-lock-it-down school of thought).

** Again, this is just how I envision it working, largely based on this Optimal Barrel Time theory. I have run it through some spreadsheets and the Quickload internal ballistics calculations, but I'm a programmer, not a mechanical engineer. I don't have quite enough hard science to back it up as fact.

Rod

I usually trust my gun enough to just calibrate the load by watching the vertical in the group. Loads that are on a node boundary seem blow up in every direction. If you subscribe to the shock wave theory, this would suggest the bullet is exiting while the pulse in at the muzzle. Between cusps, 3-5 shot groups have readable vertical dispersion (and it is quite possible to put two or three in one hole but have the fourth climb out by a bullet or two - that is why I usually shot a couple of 3-4 shot groups on my sighter before going to the record). I visualize the effect as trying to make an adjustment that will time the bullet exit a tiny touch earlier (screwing the tuner in or out by .001-.002" would make the pulse reflection times a tiny bit shorted or longer and re-position the pulse away from the muzzle as the bullet exits.

From Chris Long's paper, this graph is a model that plots bore diameter at the muzzle (choke, if you please) against the timing of an acoustic shock wave in steel. The spikes are points where the shock wave it at the muzzle and it is correspondingly "all over the place". By changing loads, a 6PPC bullet in a 21" barrel exits the barrel between .0007 and .0010 seconds -- about between the 3th and 5th spike, which might explain what we know as the low node and high node with the BIG group between them.

For tuning purposes, the more interesting graph is when you zoom in on the tiny sine-wave between the spikes. Here, the "sweet spots" are the bottom and top of the humps where there is a stable muzzle diameter for a longer period of time. A forgiving load makes those regions of time as wide as possible; tiny tweaks on the tuner let you center up on them each time you come to the bench. Note that it looks like the classic mode 1, ruler-on-the-desk sine wave that usually gets associated with barrel vibration, but in fact is behaving 10,000x faster than the mode-1 vibrations and is a muzzle-strain, not harmonic vibration.

My goal for the centerfire BR tuner is to micro-manage bullet exit time, not attempt to broaden the node by compensating for exit time (that would be the tune-for-dead-vibration-lock-it-down school of thought).

** Again, this is just how I envision it working, largely based on this Optimal Barrel Time theory. I have run it through some spreadsheets and the Quickload internal ballistics calculations, but I'm a programmer, not a mechanical engineer. I don't have quite enough hard science to back it up as fact.

Rod

M

mike in co

Guest

i think you and gene beggs should get together in the tunnel and talk and shoot some more.....you two are just plain dangerous to this game.....

mike in co

mike in co

M

mks

Guest

My goal for the centerfire BR tuner is to micro-manage bullet exit time, not attempt to broaden the node by compensating for exit time (that would be the tune-for-dead-vibration-lock-it-down school of thought).

** Again, this is just how I envision it working, largely based on this Optimal Barrel Time theory. I have run it through some spreadsheets and the Quickload internal ballistics calculations, but I'm a programmer, not a mechanical engineer. I don't have quite enough hard science to back it up as fact.

Rod

You certainly have the empirical evidence to show that your method of tuning works. But I am less sure that you have hit on the right reason for why it works. I have written before about why I think the radial mode of barrel vibration is not an important factor for tuning. The reasoning basically centers around the tenuous connection between a change in bore diameter in the MILLIONTHS of an inch and vertical dispersion on target. First, that is a really small change. And second, if it did make a difference, it should affect vertical and horizontal dispersion equally. (That bullet that is rattling

Also, I am afraid you are confusing the Calfee fantasy of a parallel node (the they'll-all-go-in-the-same-hole-if-you-lock-it-down falsehood) with the slower-bullets-will-go-in-the-same-hole-if-you-launch-them-higher idea that has a foundation in real science. See VarmintAl's simulations and Geoffrey Kolbe's experiments.

Thanks again for sharing. I love these discussions.

Keith