I just wanted to point out that with some care it's posible to hold a reamer, using a holder that has a single side handle, in a way that minimizes or almost totally eliminates the side force. Lots of folks use single handle reamer holders. One of the better selling ones, the Bald Eagle, is a single side handle.

As Butch correctlly points out, side force is the enemy. It seemed like useful information to those with such a holder to know it was possible to hold it so it would restrain reamer rotation with out exerting side force.

My comment is technically correct and is based on the properties of a "force couple" which is explained in any beginning statics book one might pick up, in college physics books, and probably most or even all highschool physics books (I don't have a HS physics book in my book case, I have the other two). It's also explained here:

http://www.engin.brown.edu/courses/en3/notes/Statics/Forcecouple/Forcecouple.htm

Bottom line, the effect of a couple is to exert a torque with out translation. In other words one can restrain a reamer from rotating using a single side handle with out exerting a side force on it if it is held in such a way that a couple is applied. That is easily done, and in fact it is probably the most natural way to grab the handle (at least for me), especially when trying to get a good start with the reamer.

I don't think a wrench, or the pusher design that started this thread, is a good design for several of reasons (although it operates on the same principle as the well known Bald Eagle Pusher). I used something similar when I cut my first chamber except I had the ball on the reamer and pushed with a flat face, I held it with a cut off wrench using my thumb to eliminate side force, the rifle shoots better than I can - I was lucky. Nothing bad happened but I didn't want to do it that way ever again.

A wrench can come off way too easily and who knows where it will go if something sticks and it has to be let go of (if the ever viligant Murphy has his way it will go the worst possible place at the worst possible time).

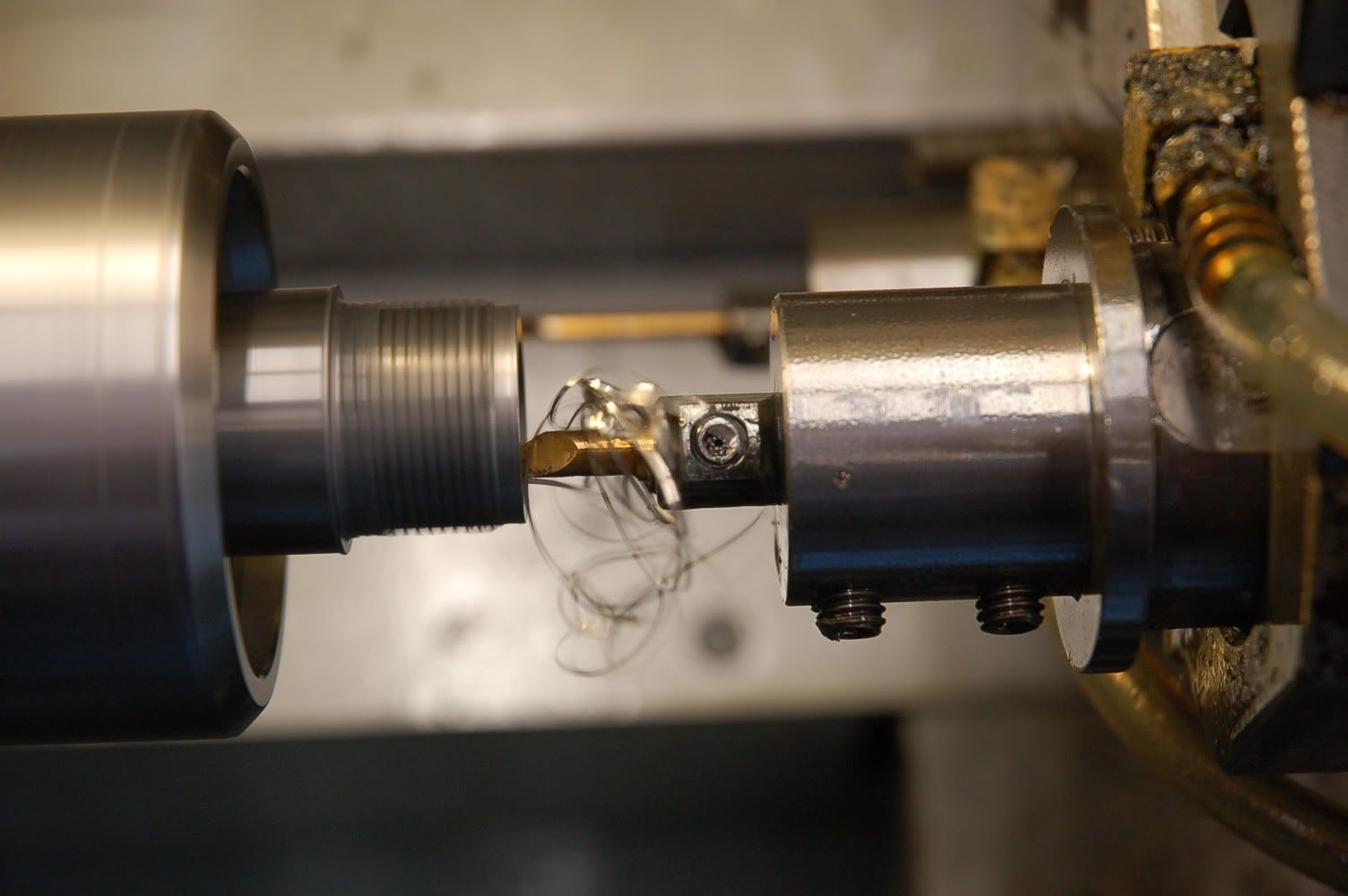

FWIW: I copied the home made one I use now from another member's web page:

The front surface of the piece in the tail stock pushes on the flat face of the collar the handle is screwed into. The reamer end fits into the hole with about .020" radial clearance. When I'm holding it my thumb presses right on the dimple where the set screw is. It's dirt simple to make out of pieces in the metal archive that most shops have. The geometry tends to self align the reamer along the axis of the bore. It won't slip and the handle is only about 3" long so it can spin freely if it has to. It works really well in a manual lathe. I wouldn't try it in Chad's setup! It isn't the only way, or even maybe the best way, but it works, and it is easy to make.

Not everybody who uses a single handle reamer pusher holds it to minimize side force. In his video, Ed Franklin, who uses a Bald Eagle reamer holder, slips the handle into a larger diameter piece of rod and rests that on his fingers on the compound. That pretty much insures the reamer sees all the side force that is possible yet he still had hundreds of satisfied customers. That said, I wouldn't do it his way either.

Everything is a trade off if one looks at it in detail. In the big picture there doesn't seem to be any one way to do this successfully, but given a specific tool, like a single handle reamer pusher, there may be a best way to use it.

Fitch