You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Threading Tool holder?

- Thread starter tinman

- Start date

Threading...

For the past two years I have been using a Carmex tool holder

(SER 0500 F16) MSC part # 08700023 On top I have a Carmex partial profile 16 ER A 60 BXC coated insert - MSC part # 05765631. Page 783-784 in the 2007/2008 MSC Big book. I assume you are talking external threads. Bro.D

For the past two years I have been using a Carmex tool holder

(SER 0500 F16) MSC part # 08700023 On top I have a Carmex partial profile 16 ER A 60 BXC coated insert - MSC part # 05765631. Page 783-784 in the 2007/2008 MSC Big book. I assume you are talking external threads. Bro.D

I like Thin Bit Tooling

Kaiser Tool company, Thin Bit tooling. They like their stuff too.

I wait until they have tool holders for free if you buy a hand full of bits.

The last order was a box smaller than a small shoe box and the price tag was over $1,200.00. They last a long time though.

Rustystud

Kaiser Tool company, Thin Bit tooling. They like their stuff too.

I wait until they have tool holders for free if you buy a hand full of bits.

The last order was a box smaller than a small shoe box and the price tag was over $1,200.00. They last a long time though.

Rustystud

jackie schmidt

New member

Tinman

If you go down to the thread that Gary Walters started that shows me doing a complete chambering job, you will see what I use for turning and threading (pictures #4 and #10).........jackie

If you go down to the thread that Gary Walters started that shows me doing a complete chambering job, you will see what I use for turning and threading (pictures #4 and #10).........jackie

Last edited:

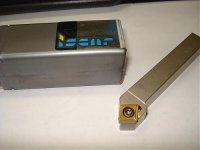

Grind a 3/8 HSS bit to thread to a shoulder. see pic

If you plan on threading miles of barrel tenon, like Nat does...I like the iscar and sandvik insert system. They have many threading systems. (the one in the pic is not a threading tool though)

As far as a holder, the aloris system, like Jackie has is the best I've used. Grizzly has a knock off that is ok, but the aloris brand one is better quality, but more $pensive.

If you plan on threading miles of barrel tenon, like Nat does...I like the iscar and sandvik insert system. They have many threading systems. (the one in the pic is not a threading tool though)

As far as a holder, the aloris system, like Jackie has is the best I've used. Grizzly has a knock off that is ok, but the aloris brand one is better quality, but more $pensive.

Attachments

Last edited:

JerrySharrett

Senile Member

From when it first came out as a stock item in the Valenite catalog till I retired in 1997, we always used the 1/2 IC on edge, triangle carbide like the TPMC-32NV. This was used in 304, 316, 316L, 319, Hastalloy, 17-4, hard SAE 4140, and a few other forgiving materials. We used a C5 grade with TiN coating. I still use that same geometry today to thread barrel tenons.

This insert is an on-edge design of 3 cutting tips. Being an on edge insert it can stand considerable abuse. A single tip will cut 20-30 or better barrels before going to the next tip. The 32NV size will work from the smallest threads to a 8 TPI pitch.

This insert is an on-edge design of 3 cutting tips. Being an on edge insert it can stand considerable abuse. A single tip will cut 20-30 or better barrels before going to the next tip. The 32NV size will work from the smallest threads to a 8 TPI pitch.

R

Rhys

Guest

I've been using the Seco Snap-Tap right hand tool holder for the past 8 years. But, after trying an idea last evening I just order the same holder in a left hand version. I'm turning the holder upside down, set the cutter just above center, and then runn the lathe in reverse. This allows you to cut the threads out from the relief cut away from the chuck, and I can then thread at 900-1300 RPM getting a cleaner thread with no chance of crashing into the shoulder or the chuck.

Rhys, you may like to have the other tool holder anyhow but you may also use a right hand threading/boring bar. Not as stiff but it won't be upside down. I use the Kennametal S1012-LSER3 which BTW is a screw on insert unlike what the internet tells you. Catalogue page C27 and if you look carefully the pic is not that exact bar, the pic is for the larger bars which are laydown style. Mike Bryant has a pic of it in his website under articles. I haven't threaded that way but can't see why not.

I just found this thing on ebay the other day. I bought one to try out. I already have a nice Kennametal holder but I had to give this a whirl. The price is very good(about$40 shipped) and its made in the USA. It will cut inside,outside and right and left hand.

Joe Hynes

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&ssPageName=STRK:MEWAX:IT&item=160314443610

Joe Hynes

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&ssPageName=STRK:MEWAX:IT&item=160314443610

Jim Wooten

Just Me

I just found this thing on ebay the other day. I bought one to try out. I already have a nice Kennametal holder but I had to give this a whirl. The price is very good(about$40 shipped) and its made in the USA. It will cut inside,outside and right and left hand.

Joe Hynes

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&ssPageName=STRK:MEWAX:IT&item=160314443610

Joe,

How did the new ebay tool holder work?

Jim

H

henrya

Guest

Here is a direct link to the Mesa Tool threading tool:

http://www.mesatool.com/product.asp?specific=138

Looks like a nice tool to me. I'd like to hear how it works too.

http://www.mesatool.com/product.asp?specific=138

Looks like a nice tool to me. I'd like to hear how it works too.

S

slugger

Guest

Did you guys try out these tools and ????

Well I got the tool holder a couple days ago and finally got to try it out. The fit and finish of it if very nice. I was just threading a piece of 1018 that I had laying around. One thing I noticed is you can't really see what is going on because the tool is so large in diameter right close to the cutting edge. It also seems to clog with chips easy because of the same thing. After cutting the thread to a decent depth, I stopped everything and blew away the aftermath and looked at the remains. The cutting edge had chipped already. I never even got close to hitting anything with it. I am not sure what grade carbide the insert is but it sure isn't very tough. Also the insert can't be turned around and used on the other end for the same side cut. They only have one right and one left cutting edge on them, not reversible. Can't say I am really impressed with it. Your mileage may very. I will take a pic later so you can see how it obstructs your view while cutting.

After grinding a HHS bit and using it, I will have to say that is the best way to go for me right now. And yes I have been listening Jerry Sharrett.

Joe Hynes

After grinding a HHS bit and using it, I will have to say that is the best way to go for me right now. And yes I have been listening Jerry Sharrett.

Joe Hynes

M.D.Spencer

New member

Hi Joe

A piece of 1018 isn't a great piece of material to practice with.... Grab an old barrel. 4140 or 416 they cut so nice!!! 1018 looks like crap or "Poo" if you watch "Dirty jobs". 1018 is gummy.. it's easy to machine... it's soft, just like gum.

A piece of 1018 isn't a great piece of material to practice with.... Grab an old barrel. 4140 or 416 they cut so nice!!! 1018 looks like crap or "Poo" if you watch "Dirty jobs". 1018 is gummy.. it's easy to machine... it's soft, just like gum.

Hey Mark, there is lots of poo in my garage.  You have seen the junk I have. Here are a couple pics of that tool holder in action, well in the quick change holder. It is pretty hard to see the cutting edge. It doesn't help that I am so short either. I haven't given up on it yet. I have a shaft to thread tomorrow, I will see if it cuts some stainless any better. One shot is from standing about normal position, the other is from almost directly above.

You have seen the junk I have. Here are a couple pics of that tool holder in action, well in the quick change holder. It is pretty hard to see the cutting edge. It doesn't help that I am so short either. I haven't given up on it yet. I have a shaft to thread tomorrow, I will see if it cuts some stainless any better. One shot is from standing about normal position, the other is from almost directly above.

Joe

Joe

M.D.Spencer

New member

Looks like a neat tool holder

$40 bucks isn't bad.. Inserts are cheap. Are you using any cutting oil?

$40 bucks isn't bad.. Inserts are cheap. Are you using any cutting oil?

Fun steel to practice on..

Find you some scrap 12L14 steel. Machines very nicely. 1018 is very poor quality steel for machining. Stainless steel comes in several series (300, 400, etc) some machines nicely others can work harden or become sticky, stringy(sp).

It is always nice to learn on something work friendly.

Nat Lambeth

Find you some scrap 12L14 steel. Machines very nicely. 1018 is very poor quality steel for machining. Stainless steel comes in several series (300, 400, etc) some machines nicely others can work harden or become sticky, stringy(sp).

It is always nice to learn on something work friendly.

Nat Lambeth