Boyd Allen

Active member

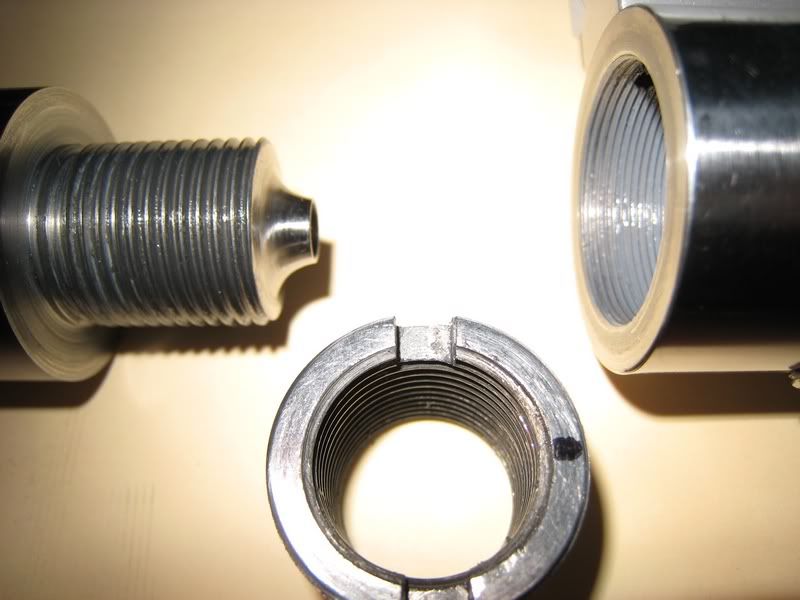

A friend knows a smith that has made bushings for 40x rimfires to accomodate a smaller tenon diameter. They incorporate recoil lug as part of a one piece unit. In your opinions, is this a desirable modification?

Another question...will a 40X work with a cone breech? If it will, is there a problem with this option? It would seem simpler, or does it complicate loading?

Thanks,

Boyd

Another question...will a 40X work with a cone breech? If it will, is there a problem with this option? It would seem simpler, or does it complicate loading?

Thanks,

Boyd