.

.

Mortenson Cpl. U.S.M.C 1890408 1959-1963

Salty old dude! That's Old Corps right there.

Semper Fidelis, brother.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shipyard stories

- Thread starter dmort

- Start date

The word "Decommissioned" was from the history of the USS Gridley. She was out of service for 1 1/2 to 2 years. Thought it might have been a change to the SM 1 or SM 2 launched by the England in the large color photo you posted. My time frame could be way off.

You said the ship has earned three"E" awards but they only showed 2. When I saw the ship "E" ribbon it had the white bars. Two bars mean 2 "E" awards?...guess not. I also thought the ship could earn "E" awards in gunnery , engineering, etc. etc.

Tim, you are right I was never in the US Navy but we spent a lot of time together.

.

Mortenson Cpl. U.S.M.C 1890408 1959-1963

Okay. Thanks for your service.....Marines can get Battle E Ribbons....Seen a few Marines on LHA's with the ribbons....

What I meant was the history showed a stack of ribbons. But, It was misleading. It is supposed to show all medals and ribbons for that ship's entire life....When I was on the Gridley, we should have been awarded 3 ribbons. But, the FC guy was late in receiving orders from Capt. and relaying them to FC OP, to fire missile. He was a huge LIB, who thought he knew how to run the ship, better than the Capt. So we fired across a safety zone...DQ'd for the year.....

For multiple ribbons. 3 small "E"'s then a big "E" for number 4.....

Ribbons/medals don't change. Just the devices added to them.....for multiple awards....

Yep. The big Red E on the stack is very prized(Engineering). And a ton of work. Very little sleep or days off....Each department might be awarded for battle group. We competed with 3 other cruisers.....

Repair the ship, train the crew, train with your battle group, go on patrol.....It's supposed to be 18 month cycle.....

Last edited:

dmort

Active member

Hong Kong

Tim, your experience in Hong Kong being berthed at a pier was a little different from mine. I was stuck in the middle of the bay on a LST. Our only way to shore and back was by a small barge. I don't who it belonged too,but with shallow or non existent siding, safety was not an issue.

We were told two things before going ashore...no tattoos (sanitation was an issue) and avoiding contact with the funky looking water that was Hong Kong Bay....another sanitation issue.

Unless you were a NCO (Petty Officer or Corporal and above) you had Cinderella Liberty. You wouldn't turn into a pumpkin if you were late reporting back to the ship. But you might wish that was actually an option.

Given the indians always out number the chiefs...there were a lot of us gathered on the pier (Marines and Sailors) for the shuttle back to the ship.

The first issue is stepping off the pier onto the barge, then the shuttle barge has to make contact with a raft , that is tied to the bottom of the ladder, that you have to climb before asking the Deck Officer for permission to come aboard.

This all has to be performed after being invited by the British Marine Garrison to their EM club.....and chugging a beer every time they said "To the Queen".

Mort

Tim, your experience in Hong Kong being berthed at a pier was a little different from mine. I was stuck in the middle of the bay on a LST. Our only way to shore and back was by a small barge. I don't who it belonged too,but with shallow or non existent siding, safety was not an issue.

We were told two things before going ashore...no tattoos (sanitation was an issue) and avoiding contact with the funky looking water that was Hong Kong Bay....another sanitation issue.

Unless you were a NCO (Petty Officer or Corporal and above) you had Cinderella Liberty. You wouldn't turn into a pumpkin if you were late reporting back to the ship. But you might wish that was actually an option.

Given the indians always out number the chiefs...there were a lot of us gathered on the pier (Marines and Sailors) for the shuttle back to the ship.

The first issue is stepping off the pier onto the barge, then the shuttle barge has to make contact with a raft , that is tied to the bottom of the ladder, that you have to climb before asking the Deck Officer for permission to come aboard.

This all has to be performed after being invited by the British Marine Garrison to their EM club.....and chugging a beer every time they said "To the Queen".

Mort

Last edited:

Tim, your experience in Hong Kong being berthed at a pier was a little different from mine. I was stuck in the middle of the bay on a LST. Our only way to shore and back was by a small barge. I don't who it belonged too,but with shallow or non existent siding, safety was not an issue.

We were told two things before going ashore...no tattoos (sanitation was an issue) and avoiding contact with the funky looking water that was Hong Kong Bay....another sanitation issue.

Unless you were a NCO (Petty Officer or Corporal and above) you had Cinderella Liberty. You wouldn't turn into a pumpkin if you were late reporting back to the ship. But you might wish that was actually an option.

Given the indians always out number the chiefs...there were a lot of us gathered on the pier (Marines and Sailors) for the shuttle back to the ship.

The first issue is stepping off the pier onto the barge, then the shuttle barge has to make contact with a raft , that is tied to the bottom of the ladder, that you have to climb before asking the Deck Officer for permission to come aboard.

This all has to be performed after being invited by the British Marine Garrison to their EM club.....and chugging a beer every time they said "To the Queen".

Mort

Pier side in Hong Kong was beautiful...Okay. We will play.

I was allowed in the NCO club of the Prince Of Wales Building... Could not buy a beer... Reminded to buy some cigars, before we left.....I bought 2 Partagas(wish I had bought a box). Best DANG Cigars ever....I didn't smoke them, till we were at Gonzo Station(for Steel Beach on the Gridley. Didn't know we had a band on board....Sundays only.). By that time. Most chewiers had run out of chew/snuff.

Wonder....Here's a pic. A subarbeque.......

Attachments

dmort

Active member

Hong Kong Again

My first time ashore, a small group of us walked into a bar and ordered a beer. We got our beer, but were told we had to drink it upstairs on the loft...it was for whites only... The British caste system was still in place.

Back on the LST, and passing through the galley to drop my mess tray, I was intercepted by an Asian woman who smiled and took it from me. What is this?...Why is a civilian on the ship? Someone said to go up on the deck and look over the side.

What I saw was a raft or a junk along side of the ship. In it were a group of Asians with long poles and rollers painting the sides with Navy Gray paint.

The Navy exchanged the garbage (slops) from the galley for labor and supplied the paint. I assumed the garbage was used to feed hogs...hope so.

There were always junks around the ship. Adults would bring young children out to dive for coins. When they came to the surface, they would hold up their hands to show you they had been successful.

Things have changed, Hong Kong has a modern airport and is a tourists destination. Are the people beyond what is seen any better off?....I don't know.

Mort

PS: Tim, why couldn't you get a drink?

My first time ashore, a small group of us walked into a bar and ordered a beer. We got our beer, but were told we had to drink it upstairs on the loft...it was for whites only... The British caste system was still in place.

Back on the LST, and passing through the galley to drop my mess tray, I was intercepted by an Asian woman who smiled and took it from me. What is this?...Why is a civilian on the ship? Someone said to go up on the deck and look over the side.

What I saw was a raft or a junk along side of the ship. In it were a group of Asians with long poles and rollers painting the sides with Navy Gray paint.

The Navy exchanged the garbage (slops) from the galley for labor and supplied the paint. I assumed the garbage was used to feed hogs...hope so.

There were always junks around the ship. Adults would bring young children out to dive for coins. When they came to the surface, they would hold up their hands to show you they had been successful.

Things have changed, Hong Kong has a modern airport and is a tourists destination. Are the people beyond what is seen any better off?....I don't know.

Mort

PS: Tim, why couldn't you get a drink?

Last edited:

"I was allowed in the NCO club of the Prince Of Wales Building... Could not buy a beer..." Oh, we got beer.

Could not BUY one in the Petty Officer's club.

I vaguely remember some Ancient Royal Navy Tradition(going back 200 some yrs.)...Good luck thing for the limie....

Petty Officer's are the Professional Part/back bone of the Royal Navy. They sign on for 10-20 yrs or something like that. Might be different now.

Plus we were tied up to the pier....They thought that was really grand.....Yanks bring their Flag Ship to the base.

Could not BUY one in the Petty Officer's club.

I vaguely remember some Ancient Royal Navy Tradition(going back 200 some yrs.)...Good luck thing for the limie....

Petty Officer's are the Professional Part/back bone of the Royal Navy. They sign on for 10-20 yrs or something like that. Might be different now.

Plus we were tied up to the pier....They thought that was really grand.....Yanks bring their Flag Ship to the base.

dmort

Active member

Flame Cutters

One day at the shipyard, a ship foreman and a machinist I knew, came into the shop and asked if I could get a project done for them ASAP. They wanted an adapter made for a portable milling machine. They had already cleared my time and made a sketch of what was needed.

My job was to lay it out to scale on steel plate, and get it cut and prepped for welding. When I got it back I was to drill a hole pattern on both sides...that was it.

When you layout anything to be flame cut, your scribe lines have to be center punched.The heat from the flame will erase any contrast between the Dykem and your scribe lines.

Being my normal anal self, my punch marks had to be very close or right on the scribe lines, and with an even spacing. On straight lines you could drag your punch and pick up a rhythm. Anything with a tight radius could be a real pain.

The ability of the cutter to follow anyone's punch marks is a real skill....it's all freehand...some of these guys could have been pen strippers.

You would just have to see it.

Mort

One day at the shipyard, a ship foreman and a machinist I knew, came into the shop and asked if I could get a project done for them ASAP. They wanted an adapter made for a portable milling machine. They had already cleared my time and made a sketch of what was needed.

My job was to lay it out to scale on steel plate, and get it cut and prepped for welding. When I got it back I was to drill a hole pattern on both sides...that was it.

When you layout anything to be flame cut, your scribe lines have to be center punched.The heat from the flame will erase any contrast between the Dykem and your scribe lines.

Being my normal anal self, my punch marks had to be very close or right on the scribe lines, and with an even spacing. On straight lines you could drag your punch and pick up a rhythm. Anything with a tight radius could be a real pain.

The ability of the cutter to follow anyone's punch marks is a real skill....it's all freehand...some of these guys could have been pen strippers.

You would just have to see it.

Mort

Last edited:

some of these guys could have been pen strippers.

You would just have to see it.

Mort

Pen strippers ???

I worked at a shipyard in San Diego. 7 yrs. For a year, I had my own shop repairing welding machines. Worked for the Structural Dept. Super....

For overtime. It was fire watch or shipfitter. So I got qualified to weld....Oh, yea. That job is an art.

Welding Engineer used to pass around a story. Not sure if it was true....He said they trained chimps to weld....Might have been a nice insult ???

Tim

Pen stripper is code for pin stripper......I thought you knew that.

Hear of pin striping for cars.....

Never heard of pen/pin stripper.

The last place I worked. Everything was called by the name on the box/item. Guy called a hammer drill, Hilde. We didn't have a Hilde.

The hammer drill was a Milwaukee....

Maybe, there needs to be more clarification. Most of the names used. Were the first name that person read or heard....So there were 10 names for a fork lift...depending on who you are talking too.

Like there were 6 different weather reports. Depending on who you were talking to.

In San Diego. We didn't talk about weather or the Padres or Chargers.......

jackie schmidt

New member

I got it and I really like your drill press setup.You are definitely a no frills kind of guy....and it works.

Pouring the chocks looks like a mess waiting to happen.

Could you send a pic of the finished installation on the one in the previous pictures?

Mort

I'm in Orange this morning, here is what the Foundation Foot looks like after the Chockfast is poured and has hardened.

http://benchrest.com/attachment.php?attachmentid=20558&stc=1&d=1515781830

It's not really that messy. The worst thing that can happen is to spring a leak, but even at that, you just cram a little duct seal into the spot.

As you see, you want a good riser above the Gear Foot so you can be assured of a 100 percent pour.

Attachments

Last edited:

The worst thing that can happen is to spring a leak, but even at that, you just cram a little duct seal into the spot.

duct seal? Is that the same as monkey sh*t??? Don't confuse that with a 3rd world country....PLS....Or even 2nd...EH!

I have spent my life in Shipyards, since we are a full service Machine Shop for the Marine Industry.

When vessels are on drydock, or even at dockside for repairs, it can get very cramped very quickly due to the large amount of persons having to work in a very limited space. This limited space is usually filled with the various large components that make the vessel work.

On any job, a good Project Coordinator is essential to see the people are not stumbling over one another in an attempted to get something done. It might be something as simple as realizing you can't be sand blasting while engines are being rebuilt, or something as complicated as ensuring all of the running gear is Machined correctly BEFORE it is installed.

If you like rigging, here is a picture of a 86 ft Pushboat Hull being lifted and placed in the water by "Big John", a 600 ton floating crane that works the Ship Channel in Houston.

The Shipyard constructs the hull upside down, then flips it and places it in the water. It can then be placed on a drydock for finishing.

The blank hull weighs about 200 tons.

http://benchrest.com/attachment.php?attachmentid=20051&stc=1&d=1505664129

http://benchrest.com/attachment.php?attachmentid=20051&stc=1&d=1505664129

http://benchrest.com/attachment.php?attachmentid=20055&stc=1&d=1505666409

Got to see Herman the German crane at LBNY. 1982. Wow. Was it big.....

Wiki does not jive with my memory....eh.

https://en.wikipedia.org/wiki/Herman_the_German_(crane_vessel)

dmort

Active member

Hear of pin striping for cars.....

Never heard of pen/pin stripper.

The last place I worked. Everything was called by the name on the box/item. Guy called a hammer drill, Hilde. We didn't have a Hilde.

The hammer drill was a Milwaukee....

Maybe, there needs to be more clarification. Most of the names used. Were the first name that person read or heard....So there were 10 names for a fork lift...depending on who you are talking too.

Like there were 6 different weather reports. Depending on who you were talking to.

In San Diego. We didn't talk about weather or the Padres or Chargers.......

Tim

My PC would not accept the plural of striper with a pen or pin as a prefix.

I just knew the Benchrest folks and you would cut me a little slack....everyone knows what I meant....right?

Even though I like to B.S. your reading the best effort of someone who got a "D" in English...absolute truth.

My English teacher was single, young and a real fox. Between thinking about her and my 47 Ford there wasn't room for anything else.

Mort

PS: The "D" was a gift

dmort

Active member

Mort.

What's the first thing done, when a ship is in drydock? Pier services are rendered......

For anyone working on the ship who had to take a crap...you can't use the head in dry dock . The sand blasters would chase you down.

Mort

PS: Did I pass the quiz?

jackie schmidt

New member

Jackie

It looks better than I thought it would . Someone took a little care with the pour.

Is the riser going to stay?

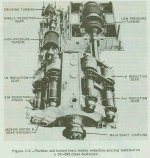

I have never seen the reduction gears on a Navy ship. I was told the hatch is always locked for security reasons.

Thanks for the pic.

Reduction gears on large steam and gas turbine powered vessels are very expensive and extremely precision pieces of equipment. They have to reduce RPM's of a 4000 RPM turbine down to around 200 turns for the prop shaft. Most are double reduction, and have two inputs, or pinions. One off of the high pressure turbine, one off of the low pressure.

Here is a view of a typical Turbine System from a WW-2 Destroyer. It's probably a 30,000 unit. You can see the high and low pressure turbines and the double reduction.

http://benchrest.com/attachment.php?attachmentid=20559&stc=1&d=1515888444

From what I know, the Navy, and even some commercial interest, never owned the turbine/reduction gear sets. They rented them from GE.

One good thing about these huge pieces of equipment. They were just about good for the life of the ship.

Attachments

Last edited:

jackie schmidt

New member

Jackie

It looks better than I thought it would . Someone took a little care with the pour.

Is the riser going to stay?.

The shipyard will remove the dams, jacking screws, and duct seal, and with a disc sander, trim the rough edges off the riser and make it look good.

This boat is due for completion and delivery in March.