M

MBrenner

Guest

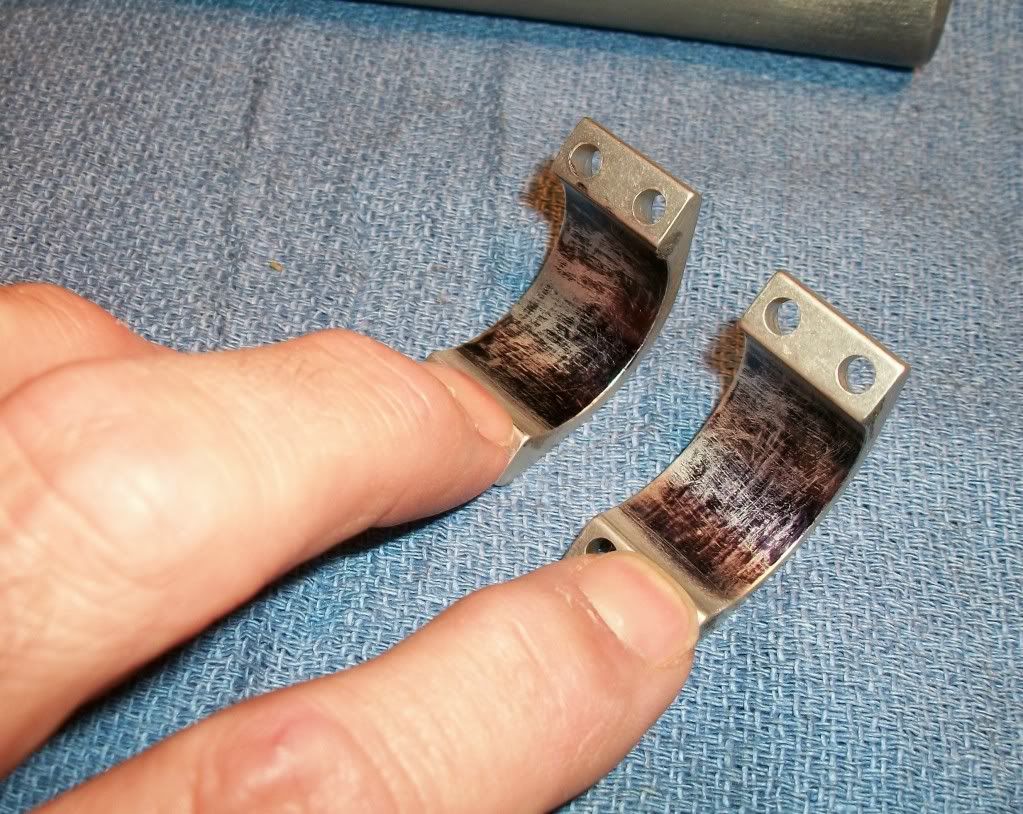

Have a bench gun with a Panda action, Kelbly 30 mm double rings with lowers lapped, and a new Valdada scope on a 30BR. I carefully cleaned both scope and rings and mounted the scope with a drop of fingernail polish on each lower ring. I then tightened both rings as I have for the past fifteen years for no scope creep, careful to even out the ring's side space, certainly not touching. This was actually my second attempt to mount this Valdada because it creeped the first time, hence the fingernail polish to prevent movement. Unfortunately, it creeped again in the next match, not as much as the first time, but enough to effect my score. I'm hesitant to tighten the rings even more for fear of damaging the scope tube, so I would appreciate any suggestions. The Valdada is a really nice scope and I would like to use it! Thanks for your thoughts.