I have something I would like to share and I'm not sure if it belongs here or in the ammo thread. I'm going to put it here and maybe add it to the ammo thread as well.

As I mentioned before my chambers are rarely identical, then again, the ammo I shoot, lot to lot isn't identical.

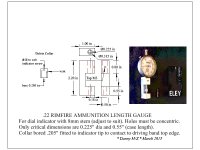

Pete my benchmark is to engrave the bullet up to the second driving band and no further. When I first discovered this, I thought I could fix it, so I came up with a tool.

View attachment 25113View attachment 25114

This tool allows me to do several things. I can spin the bullet to see if it runs true.

Years ago, the crimp on Eley was so loose you could rotate the bullet in the case. Sometimes the indicator would straighten the bullet as I turned the handle.

But the main purpose of this tool was to cut the first driving band so the driving band started the same place on every round. My thought was it would be consistent.

I spent hours

fixing my bullets. At this same time, I was weighting and measuring the rim thickness on each round.

I look back now, and wonder was it really worth it. I don't think so, but you would never have talked me out of doing it.

Tim,

I do finish my chambers or at least try to. But I also believe every barrel can benefit by having a "Post Chamber Lap".

This is a lot of trouble, but I believe, worth it.

This is quite different from lapping an unlapped blank. At least the way I do it.

Paul Tolvalstat is probably the best barrel lapper in the world today. He will probably laugh if he reads this.

But after I cut my chamber and do my finishing work, I clean the barrel thoroughly. Then I cast a lap in the barrel and work it lightly, just a couple of passes all the way through the barrel.

Yes, I have gotten the lap stuck in the bore, and yes it pisses me off, but when I finish, I feel I have done all I can do.

View attachment 25115View attachment 25116

I rarely have trouble with fouling, so I don't recall ever reworking a barrel for fouling. That said, most of the time I have to take the barrel back off and make adjustments.

I try not to cut extractor cuts until the rifle is shooting to my satisfaction. I have cut chambers off and had another go. Every time I've done this the barrel never seemed to get better.

TKH (4628)