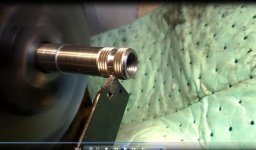

I made this FL bushing die, a seater(copy of LEE dead length seater), and a form die.

This was my first attempt to make a set of dies(apr a year ago).

In the process, I thought it was a little stupid to turn down the top of the die.

So, before making the form die, I backbored the dieholder and realigned it. This way, I can screw the die through the headstock, for the first setup(bore/ream the chamber end).

Bore, single point thread, "face of" the dieholder works. Cases and loaded round is as concentric as with any of my regular dies.

But is there a faster/better way?

I suppose it is.

I thought of the steady rest. Or a tube with 4 + 4 bolts(and a backstop for the die). Then I can align it, for sure.

Ended up with the "screwup" thing, hehe.

I will try to make dies with the above methods too. Then I can compare.

Any other suggestions? Written words, pictures, or video.

There is thousands of videos out there, regarding thread and chamber a barrel. But almost nothing about dies. STRANGE.......

You can see that my pictures, is "screenshots" from video files.

When I have tryed the other methods, I will try to post videos on ytube. But time, my friens, time.