Splain to me how the bullet will be cockeyed if the case is aligned in the chamber provided the neck is not catty wampass and the brass isn't flexing like used bubble gum. The case is a tighter fit than the neck, remember. Add to that the fact that the bullet has to been sent on its way as the bullet seating tension is such that it, the bullet, is released with less resistance that that of brass stretching. While it is true that the neck expands and seals the "chamber" the true resistance doesn't begin until the bullet engages the barrel beyond the free bore.

I can't speak for the other guy who disagrees but, I think I read well and I absorb what is written by people more learned than you or me. I believe this subject is outside of your area of expertise.

I don't know what a lot of this means, explains or implies (except the last part), but it seems to support my contention without meaning to.

Here's what DOES happen, unless your chamber is designed like a Weatherby or Edge.

#1-As pressure builds in the case the bullet slides forward to stop on the "leade" or tapered beginning of the lands..... or, in most accuracy situations

it's already there. most bullets in accurate rigs are seated within a few thou of the lands.

#2-As pressure continues to build the case pops out, neck first to seal the chamber. This is it's primary function. If this function is compromised the results are dramatic. Some of us have actually experienced this, some of us can state with fair certainty that the neck DOES POP OUT TO SEAL because when it doesn't all sorts of cool stuff happens. Some of us have tested and observed that the smart guys who wrote the books were speaking truth.

#3-When the neck pops out to seal on a typical chamber, THE REAR OF THE BULLET IS STILL IN THE NECK. The last guiding support on the bullet is the neck...... not the body of the case or the headspace, the NECK. But the neck just LET GO....This leaves the base of the bullet unsupported.

The rest seems obvious. The bullet hasn't moved yet, the rear end is waggling in the breeze, the front end is butted up to the leade, trying to engage but needing 600lb of pressure to do so........ and it's just hanging there, unsupported, or it may have a section of freebore to "hold it in place."

But for those of you who, like FBecigneul, feel I'm unqualified to make these assertions please do some research. Start with Harold Vaughn's 'Rifle Accuracy Facts' and continue with Rinker's 'Understanding Firearms Ballistics' and finish up with Howell's 'Designing and Forming Custom Cartridges For Rifles and Handguns' and you'll have a fair understanding of what goes on.....

Beats guessing.

For those of you who want to TEST this stuff, do like I have...... buy reamers in sets of six with progressively larger necks, buy them with zero freebore and buy a bunch of throating reamers. I can help you with the design (diameter, leade angle, steps/angle changes if you want, I've tried up to three) and show you how to modify Kiff's throaters for hand-held use. Now with a few notebooks and a range of powders and bullets you can empirically TEST for what affects what.

Like I have.

Or, have guessers explain it to you, and then you can go "straighten cases" and spend lots of time and money on "concentricity" and such, spend your moneys however you want..... Or you can listen to someone who's actually SPENT tens of thousands of dollars on junk guesses. Someone who actually takes these guesses and tries them out....... and believe me a lot of the guesses I've spent money on are from Bench Rest Hall Of Fame builders and shooters. Being a BR shooter doesn't make anyone an expert on building stuff. There's no substitute for SPENDING THE MONEY. Somehow, spending thousands of dollars chasing people's pipe-guesses really brands the results into one's memory. Ask me sometime about the dollars I've spent trying to "contain caseheads" against expansion, the foolish garbage I've bought into attempting to "eliminate the click" until I just went out and did it. Or about buying into the theory that "sizing only half of the neck aids linearity". Or the theory that "cases blow out in the top side so indexing will help to"....blahh blahh blahhh... Ask about the numerous "case straighteners" I own...

But you'd better have a lot of time.

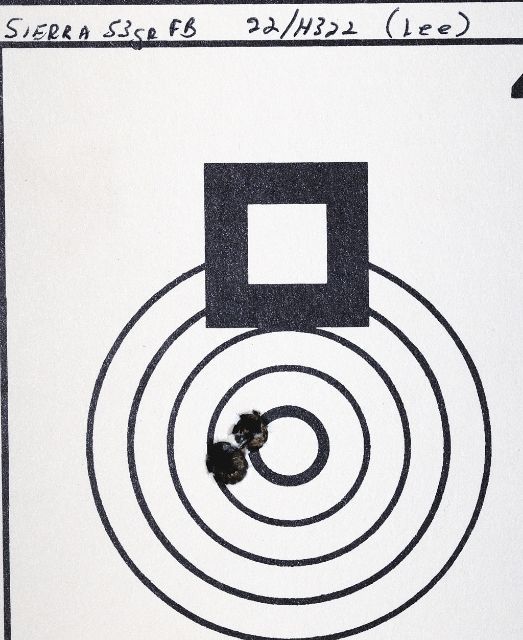

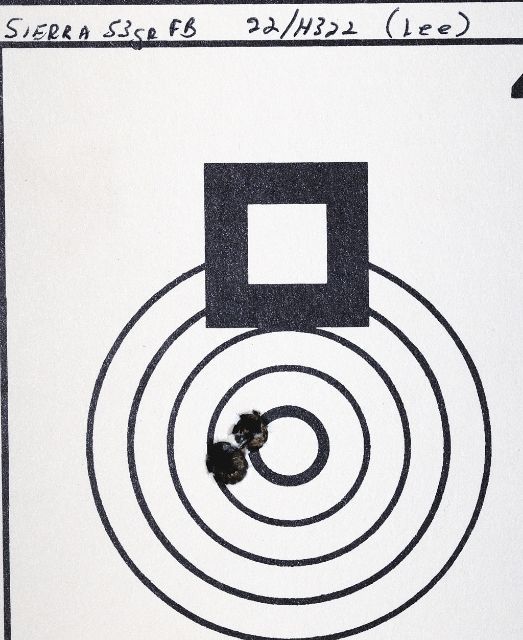

I've made cases and fitments so clean that you couldn't find runout anywhere and the guns shot like dung. And conversely, I now have rifles where you can just throw loads at them and they shoot like crazy.

I went out and bought a lathe because it was cheaper than paying for other people's guesses.

So please, some of you qualified guys explain for the op just how the body of the case "holds the bullet in alignment?" during the firing cycle....I can tell you how it DOESN'T, and if you want verification from a rocket scientist ask Harold Vaughn.

I have.

al