You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LAPUA 220 Russian cases down the drain?

- Thread starter CarlosP

- Start date

Results

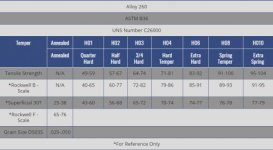

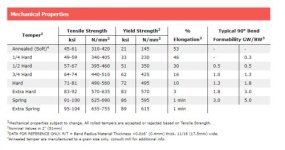

Since BroD has revealed which sample is gold box, and which is blue box, I will post the results. If Jackie wants to confirm the samples, he can. Remember that at this point, no hardness testing has been completed. I say this, because when it comes to yield strength, the hardness of the material is a very important factor. In this case, C260 brass can vary in yield strength from annealed at 21 KSI to the hardest at 89 KSI. So please trust me when I say we do not know enough at this point.

At this point the only evidence of the gold box holding up better under pressure is a trace of iron in the brass.

Don't forget the test results from accurate shooter that showed some newer 6BR Lapua brass with much less zinc content.

Other concerns have been raised by Richard when it comes to sizing dies, and he makes a valid point. On the other hand, Jackie started seeing a problem about 1 1/2 years ago. I believe he saw a change in the brass, and do not believe he changed anything else. If he used the same chamber reamer, sizing die, and the same load, then how could it be the sizing die? Maybe the die has worn a bit.

Sample # 3 has nothing to do with Lapua. I threw in a SSA 6.8 SPC case because I knew it held up to very hot loads. In this instance, it was necked down to 6mm, and pushes a 70gr bullet at over 3500 fps without loosening primers.

Michael

Since BroD has revealed which sample is gold box, and which is blue box, I will post the results. If Jackie wants to confirm the samples, he can. Remember that at this point, no hardness testing has been completed. I say this, because when it comes to yield strength, the hardness of the material is a very important factor. In this case, C260 brass can vary in yield strength from annealed at 21 KSI to the hardest at 89 KSI. So please trust me when I say we do not know enough at this point.

At this point the only evidence of the gold box holding up better under pressure is a trace of iron in the brass.

Don't forget the test results from accurate shooter that showed some newer 6BR Lapua brass with much less zinc content.

Other concerns have been raised by Richard when it comes to sizing dies, and he makes a valid point. On the other hand, Jackie started seeing a problem about 1 1/2 years ago. I believe he saw a change in the brass, and do not believe he changed anything else. If he used the same chamber reamer, sizing die, and the same load, then how could it be the sizing die? Maybe the die has worn a bit.

Sample # 3 has nothing to do with Lapua. I threw in a SSA 6.8 SPC case because I knew it held up to very hot loads. In this instance, it was necked down to 6mm, and pushes a 70gr bullet at over 3500 fps without loosening primers.

Michael

Attachments

Last edited:

jackie schmidt

New member

Confirmation by....

#1 is new blue box

#2 is old gold box

#1 is new blue box

#2 is old gold box

This Winter, I am going to rethink my entire 6PPC program. I have shot the same basic combination for years, but that might now be ended.

I always said that we owe a lot of the success of the 6PPC to the Lapua 220 Russian Case, and it's ability to survive at the pressures we shoot. That might now be a thing of the past.

Last Sunday, I put a new Bartlien 13.5 twist on my LV, and went up to Tomball. I took 12 band new cases to test with. I tried 29.2 and there abouts, not that good. I put my standard 30.3 grn load behind a Bart's 68 BT, and the Rifle came to life. By the third firing, the primers had zero feel going into the cases.

I know a lot of shooters are saying......"this is BS, you are doing something wrong". Well, I am shooting the same barrels, the same lot of powder, the same bullets, the same dies, the same primers, the same reamer, the same neck tension, and the same Rifle that I have been shooting for years.

The only thing different is the brass. But, we all know that it can't possibly be that there just might be something that Lapua is doing different. Right?

Send this to Lapua and ask them...

Mike Bryant

Active member

If you think about all of this from Lapua's viewpoint and product liability, when we take the .220 Russian case and neck it up to 6mm and then fireform it to 6 PPC, we have substantially changed their product into something that's not very close to what they originally manufactured. That pretty well takes the monkey off their back as to product liability. Then we take it and load it with upwards of 30 gr of 133 which generates no telling how much pressure. According to the Vitavourhi, loading manual 28.2 gr of 133 is what they list as a maximum load for 133 with a 68 gr bullet with a maximum pressure of 58725 psi. I haven't seen a load of 28.2 gr of 133 in 20 years. For years, 28.8 gr was what seemed to work in my rifles. I haven't shot that light a load in years. It would be interesting to see what some of these 30+ gr loads are actually running pressure wise. Then we complain because we are getting loose primer pockets or a click at the top of the bolt stroke. It would probably scare us to death if we actually knew what pressures we were running. It wouldn't surprise me if we weren't hitting 80 to 85,000 psi or maybe more. I don't think that there is any other sport than runs on the ragged edge of pressure that we have been using for the past 10 or more years.

The results, and what they mean.

The final numbers are in. I'm not surprised by the hardness test, since the alloy was nearly the same, except for the trace of iron in the gold box 220 Russian brass. To see the results, please refer to this link:

http://forum.accurateshooter.com/threads/lapua-blue-box-brass-alloy.3934345/page-3

Now that you have seen the results, the attached charts will show you how the Rockwell B hardness translates to the actual yield strength of the case head. We will use a hardness of 94 RB for the gold box, and 92 RB for the blue box at the inside of the case head, and 83 RB for the bolt face side hardness of both gold box and blue box brass. Please keep in mind that the blue box sample is from about 3 or 4 years ago, and may not reflect what shooters have been seeing in the last 1 1/2 years or so. If any shooter wants to send Jason a sample of a new lot of 220 brass, please do so.

The inside of the case head hardness falls in the H010 extra spring temper hardness range. The bold face side falls in the H04 hard temper range. If we run an average case head hardness, we get about 89 RB, which falls right between H06 extra hard temper, and H08 spring temper. If we look at the second chart, you will see that this puts the case head yield strength between 83,000 PSI, and 86,000 PSI. With the slight hardness advantage for the gold box, I would put it at the 86,000 PSI range, and the blue box at the 83,000 PSI range. So for those wondering if we are using loads up around 85,000 PSI to loosen our primer pockets, the data seems to say you are spot on.

I would have liked to see a greater advantage in the gold box sample that I sent. Since that wasn't the case, maybe someone will step forward with a known lot of brass that seems to be weaker.

For bigger charts:

https://www.meadmetals.com/metal-products/brass/physical-chemical-properties

http://www.olinbrass.com/resources/alloy-data-specifications/C26000-(ASTM-B36)-Cartridge-Brass

Michael

The final numbers are in. I'm not surprised by the hardness test, since the alloy was nearly the same, except for the trace of iron in the gold box 220 Russian brass. To see the results, please refer to this link:

http://forum.accurateshooter.com/threads/lapua-blue-box-brass-alloy.3934345/page-3

Now that you have seen the results, the attached charts will show you how the Rockwell B hardness translates to the actual yield strength of the case head. We will use a hardness of 94 RB for the gold box, and 92 RB for the blue box at the inside of the case head, and 83 RB for the bolt face side hardness of both gold box and blue box brass. Please keep in mind that the blue box sample is from about 3 or 4 years ago, and may not reflect what shooters have been seeing in the last 1 1/2 years or so. If any shooter wants to send Jason a sample of a new lot of 220 brass, please do so.

The inside of the case head hardness falls in the H010 extra spring temper hardness range. The bold face side falls in the H04 hard temper range. If we run an average case head hardness, we get about 89 RB, which falls right between H06 extra hard temper, and H08 spring temper. If we look at the second chart, you will see that this puts the case head yield strength between 83,000 PSI, and 86,000 PSI. With the slight hardness advantage for the gold box, I would put it at the 86,000 PSI range, and the blue box at the 83,000 PSI range. So for those wondering if we are using loads up around 85,000 PSI to loosen our primer pockets, the data seems to say you are spot on.

I would have liked to see a greater advantage in the gold box sample that I sent. Since that wasn't the case, maybe someone will step forward with a known lot of brass that seems to be weaker.

For bigger charts:

https://www.meadmetals.com/metal-products/brass/physical-chemical-properties

http://www.olinbrass.com/resources/alloy-data-specifications/C26000-(ASTM-B36)-Cartridge-Brass

Michael

Attachments

Last edited: