K

keninsb

Guest

Hi guys. I am a newbie here and am looking forward to gaining some valuable knowledge and being able to reciprocate (when I can).

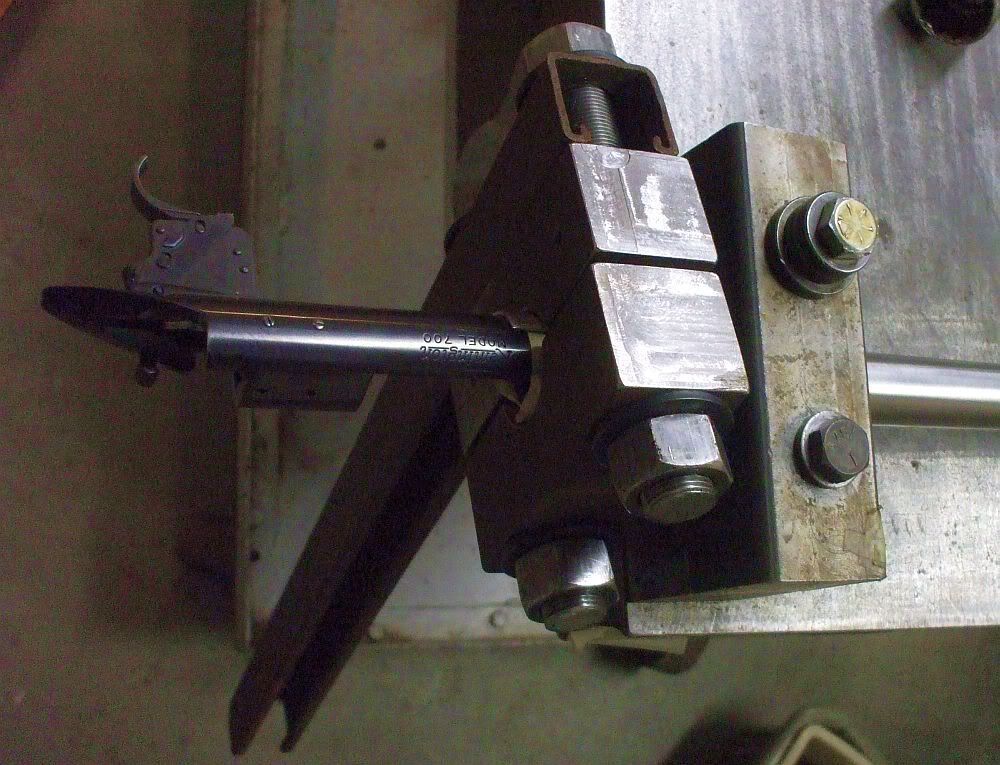

I am really sorry to make my first post a thread jack, but I have a question regarding the 700 barrels as well. You all have covered how to remove the barrels so I am covered there. My questions is this: What is required (besides the tools already mentioned and a torque wrench) to install an aftermarket barrel on a Remy 700? Can you get away with a GO NO/GO gauge set or will the barrel have to be sent to a gunsmith for the install?

Any help is GREATLY appretiated, and I apologize again for the thread jack.

Ken

I am really sorry to make my first post a thread jack, but I have a question regarding the 700 barrels as well. You all have covered how to remove the barrels so I am covered there. My questions is this: What is required (besides the tools already mentioned and a torque wrench) to install an aftermarket barrel on a Remy 700? Can you get away with a GO NO/GO gauge set or will the barrel have to be sent to a gunsmith for the install?

Any help is GREATLY appretiated, and I apologize again for the thread jack.

Ken