All these guys are right on...........ONLY the actual chamber will tell you what's happening. Soooooo, using your own chamber just seat some bullets long and use the rifle to set them. Some thoughts.

----If you're sticking bullets you'll probably have to do as Randy says, back off incrementally until she don't stick.

----Using a SILVER Sharpie is a cool trick, works even better than black.

----Using a tighter neck bushing or a thicker neck or more neck tension will result in a deeper "jamset" dimension until you stick the bullet, this ain't rocket science but you do gotta' think just a little.

----Depending on the match of your ogive to your leade angle you'll find some bullets which show only .005 from "touch" to "jamset"......... and other bullets. typically those with long VLD ogives, will show as much as .090 difference from "touch" to "deeply jammed".

----There are no absolutes here, no "perfect setting" to strive for. What you're looking for is a baseline, a spot from which to work in and out. Many folks use a "square" mark as reference, many more go with a mark twice as long as it is wide and others just use the bushing that they shoot with and jamset it and use THAT for their baseline whatever it looks like. It's ONLY A REFERENCE, that's the key. I've seen guys come on these boards and argue about the "perfect oal". goofy.

----The measurement changes over time. This is a good reason to use the "jamset it with your normal bushing" routine. You can gain a feel over time for how your lands are holding up. Using the same FORCE each time, the result of using the same bushing, you'll be able to monitor your lands.

----I wouldn't ever lube a bullet because it'll not only give you a MEANINGLESS read, it'll also false on you.

----I see no need to measure anything as far as the marks go.

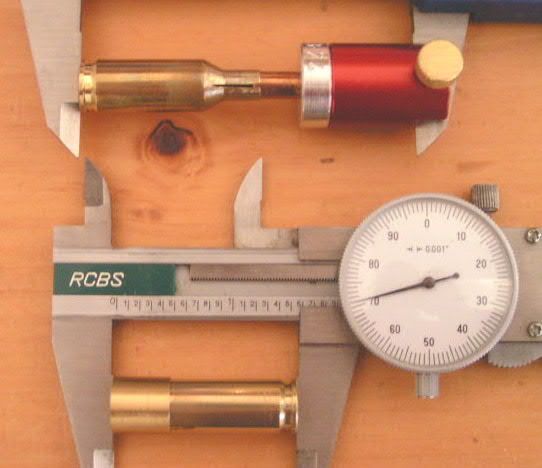

----Measure only with an ogive tool, I use the Sinclair "nut", and WRITE THIS STUFF DOWN!!! I've got friends who are forevermore GUESSING and scratching their heads every time they go back to the bench. Asking ME "what was my OAL last year?"............

hth

al