NezRongero

Member

With sponsorship support from Shilen for the last 2 years, I have been cranking out AR barrels for TX Juniors high power team, totalling 24 active participants in the program this year, and we are still actively recruiting. At the rate they are going with our training sessions and shooting in matches, our best guess they will go through a barrel a season. Though I am not in the business, just providing free barreling work for the kids is enough to keep me busy in the garage at the start of the season.

The skill level of our kids varies from Marksman to High Master. There are but a couple at the HMs, mostly are Sharpshooter and Expert level shooters, we are expecting some to move to Master classification this year.

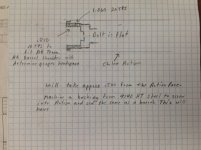

Having gone through the lengthy intro, I am looking for ideas how to test the AR barrels to determine precision. I read about barrel blocks in some rail guns, don't really know how effective would that be if I were just going to clamp the barrel past the receiver. I could drill a hole through the block for the gas tube. Or would it be better just to install a free float tube and clamp on the tube?

On the platform, my thoughts would just something adjustable bolted to linear bearing. Where I need some suggestion is what material to mount assembly to for a base that is stable enough to minimize warping. Would glued 2 layers of 3/4 MDF suffice? Or steel plate be the preferred material?

Another crossed that my mind is to find a small lathe bed with carriage that I can mount the adjustable platform.

A used return to battery would probably be a good option, I don't think I can sell the going price to the team for funding.

One of the reasons I want to test the barrels so we issue the best barrels to our top shooters who are in contention for winning matches

A lot of matches these days are determined by Xs or 1 or 2 points since CMP and NRA allowed up to 4.5X scopes for service rifles. Right now we just issue barrels and tested in a completed up by the shooter.

As the example an upper was returned to team management as not shooting well enough at 600 yards. We issued the upper to our top junior shooter to shoot at the mid range match. With no zeroes for her on the upper, she lost 2 points initially, but end up with 198-12Xs at 600 in a switching wind.

The SS ratchet barrels we get for free from Shilen shoot, but most likely some may shoot better than others. The high power scoring rings are very generous with 1 MOA X ring, a really good shooting one would mean higher X count at 600, and cleans with high X count at short range, 200 and 300, even considering shooting the rifle on your elbow and sling.

Again, I am looking for opinion on what would be a good system to test AR barrels grouping capability

Thank you all

Nez

The skill level of our kids varies from Marksman to High Master. There are but a couple at the HMs, mostly are Sharpshooter and Expert level shooters, we are expecting some to move to Master classification this year.

Having gone through the lengthy intro, I am looking for ideas how to test the AR barrels to determine precision. I read about barrel blocks in some rail guns, don't really know how effective would that be if I were just going to clamp the barrel past the receiver. I could drill a hole through the block for the gas tube. Or would it be better just to install a free float tube and clamp on the tube?

On the platform, my thoughts would just something adjustable bolted to linear bearing. Where I need some suggestion is what material to mount assembly to for a base that is stable enough to minimize warping. Would glued 2 layers of 3/4 MDF suffice? Or steel plate be the preferred material?

Another crossed that my mind is to find a small lathe bed with carriage that I can mount the adjustable platform.

A used return to battery would probably be a good option, I don't think I can sell the going price to the team for funding.

One of the reasons I want to test the barrels so we issue the best barrels to our top shooters who are in contention for winning matches

A lot of matches these days are determined by Xs or 1 or 2 points since CMP and NRA allowed up to 4.5X scopes for service rifles. Right now we just issue barrels and tested in a completed up by the shooter.

As the example an upper was returned to team management as not shooting well enough at 600 yards. We issued the upper to our top junior shooter to shoot at the mid range match. With no zeroes for her on the upper, she lost 2 points initially, but end up with 198-12Xs at 600 in a switching wind.

The SS ratchet barrels we get for free from Shilen shoot, but most likely some may shoot better than others. The high power scoring rings are very generous with 1 MOA X ring, a really good shooting one would mean higher X count at 600, and cleans with high X count at short range, 200 and 300, even considering shooting the rifle on your elbow and sling.

Again, I am looking for opinion on what would be a good system to test AR barrels grouping capability

Thank you all

Nez