You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

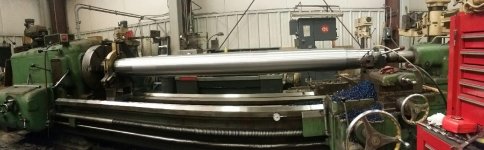

American Pacemaker lathe

- Thread starter Hillbilly

- Start date

Butch Lambert

Active member

Hillbilly, That lathe might fit in the spindle of one of Jackie's.

Butch Lambert

Active member

Butch it's a 25x120 lathe. That is a 9.5 inch shaft 10 ft long my machinist friend is making a shaft for a coal mine hoist

Hillbilly, I know exactly what you pictured.

jackie schmidt

New member

The American Pacemaker was, and still is, a great lathe. Heavy construction, hardened detachable ways, all roller bearing.

The one in Hillbilly's post is doing what it was designed to do, move a lot of metal.

The biggest complaint that many had about them was the clutch. This was Americans answer to stopping and staring a large machine with a heavy work piece. If not adjusted correctly, it could slip under heavy loads. There was a fine line between getting the clutch engagment tight enough to take the loads that these lathes were designed to take, and being able to get it engaged and disengaged easily.

We never owned a Pacemker, but this is an old American we have that has the same type of clutch. We bought this machine 30 years ago out of government storage, all we use it for now is boring long NCB liners that we shrink onto some shafts in way of the bearings.

The carriage is massive, giving great support when overhanging a long boring bar.

http://benchrest.com/attachment.php?attachmentid=18802&stc=1&d=1483110013

Old machines such as this have little value in today's machinery market. But for a single purpose use as we have this one performing, they are as good as anything on the market.

Attachments

Last edited:

Pete Wass

Well-known member

Here I go again

A lad named Jay Kilroy has one and has a short YouTube series of his taking the headstock apart to remove a broken gear. Impressive innards, I must say. There was a suggestion recently that he may be putting it back together soon. Looking it over, I couldn't imagine just one gear tooth breaking out unless it was a fault from the manufacturing. Classy old machine, nevertheless.

A number of YoyTube posters have monster lathes because of the lack of their value these days. The hobbiests are saving our history. Helps the phase converter market as well as many do not have three phase power at home.

Monarchs seem to have an edge with regard to the old iron being saved, just off the cuff? Were they more durable or plentiful?

Question: who will save the Bullard?

Pete

A lad named Jay Kilroy has one and has a short YouTube series of his taking the headstock apart to remove a broken gear. Impressive innards, I must say. There was a suggestion recently that he may be putting it back together soon. Looking it over, I couldn't imagine just one gear tooth breaking out unless it was a fault from the manufacturing. Classy old machine, nevertheless.

A number of YoyTube posters have monster lathes because of the lack of their value these days. The hobbiests are saving our history. Helps the phase converter market as well as many do not have three phase power at home.

Monarchs seem to have an edge with regard to the old iron being saved, just off the cuff? Were they more durable or plentiful?

Question: who will save the Bullard?

Pete

Last edited:

Butch it's a 25x120 lathe. That is a 9.5 inch shaft 10 ft long my machinist friend is making a shaft for a coal mine hoist

I thought it was an Unlimited barrel...

I do my part to save the Bullards!

We have:

24" spiral drive

30" spiral drive

36" cut master

42" cut master

60" hydrashift (apparently very rare bullard has no records for it we rebuilt it 3 years ago including planing and scraping the cross rail I power scraped it myself using a 10ft camel back straight edge for reference)

60" King

And last but not least we just moved in a 120" Betts...it is a monster!

Oh and a 42" Manutrol with a hydraulic leak that was given to me by the owner of the Betts

I would like to have a large cutmaster if anyone runs across one something 54" or bigger.

We have:

24" spiral drive

30" spiral drive

36" cut master

42" cut master

60" hydrashift (apparently very rare bullard has no records for it we rebuilt it 3 years ago including planing and scraping the cross rail I power scraped it myself using a 10ft camel back straight edge for reference)

60" King

And last but not least we just moved in a 120" Betts...it is a monster!

Oh and a 42" Manutrol with a hydraulic leak that was given to me by the owner of the Betts

I would like to have a large cutmaster if anyone runs across one something 54" or bigger.

jackie schmidt

New member

I do my part to save the Bullards!

We have:

24" spiral drive

30" spiral drive

36" cut master

42" cut master

60" hydrashift (apparently very rare bullard has no records for it we rebuilt it 3 years ago including planing and scraping the cross rail I power scraped it myself using a 10ft camel back straight edge for reference)

60" King

And last but not least we just moved in a 120" Betts...it is a monster!

Oh and a 42" Manutrol with a hydraulic leak that was given to me by the owner of the Betts

I would like to have a large cutmaster if anyone runs across one something 54" or bigger.

Save the Bullard, indeed. Here is a horror story or lovers of older machine tools.

Back in the 1950's and through the middle 70's, there was a large Shop in Houston over on the Greens Bayou Industrial Complex.

Their name was Greens Bayou Engineering. They specialized in servicing the Marine Industry, much as my Shop does now.

Union problems, poor management, and the demise of Todd Shipyards and the like caused them to shut down in the late '70's. One machine they could not dispose of was a huge Niles "Bullard" that would swing up to 25 feet. They mainly used it to bore large propellars.

The problem was, much of the machine was imbedded in about 10 feet of concrete. You just couldn't pick it up and move it.

The machinery broker finally told anybody that could get it out could just have it. No luck.

They finally called in a scrap dealer who brought in jack hammers and arc gougers. The more ire less busted it out, and cut it up with arc gougers in small enough prices to haul to the scrap yard.

A sorid end for such a historic machine.

Last edited:

JerrySharrett

Senile Member

American Pacemaker, Cincinnati, Ohio, Eggleston Ave. Been there many times. We bought 25-30 big engine lathes from them in the 1968-1990 time period.

That one will not fit in your shop Chance.

.

.

dmort

Active member

Monarchs

My favorite machine was a Monarch. I don't remember how old it was but it was well made and very accurate. The Cadillac of lathes.

A lad named Jay Kilroy has one and has a short YouTube series of his taking the headstock apart to remove a broken gear. Impressive innards, I must say. There was a suggestion recently that he may be putting it back together soon. Looking it over, I couldn't imagine just one gear tooth breaking out unless it was a fault from the manufacturing. Classy old machine, nevertheless.

A number of YoyTube posters have monster lathes because of the lack of their value these days. The hobbiests are saving our history. Helps the phase converter market as well as many do not have three phase power at home.

Monarchs seem to have an edge with regard to the old iron being saved, just off the cuff? Were they more durable or plentiful?

Question: who will save the Bullard?

Pete

My favorite machine was a Monarch. I don't remember how old it was but it was well made and very accurate. The Cadillac of lathes.

Butch Lambert

Active member

My old Monarch 10EE just moving it in.

It has taper, ELSR, and is the 4,000 RPM version. Came with 3 jaw Tru Adjust and a new 4 jaw, a few face plates, collet closer, and a wedge type Aloris tool post. 10EE are variable speed with a clutch. I love it even though the headstock is gawd awful long and between centers "20" is very short. Talk about heavy, smooth, and quiet. Yes, I have 2 extra sets of the very hard to find power tubes.

It has taper, ELSR, and is the 4,000 RPM version. Came with 3 jaw Tru Adjust and a new 4 jaw, a few face plates, collet closer, and a wedge type Aloris tool post. 10EE are variable speed with a clutch. I love it even though the headstock is gawd awful long and between centers "20" is very short. Talk about heavy, smooth, and quiet. Yes, I have 2 extra sets of the very hard to find power tubes.

JerrySharrett

Senile Member

My favorite machine was a Monarch. I don't remember how old it was but it was well made and very accurate. The Cadillac of lathes.

The Cadillac of the big lathes in the 1940-1970 period was Leblond.

After the 1970's the US machine tool manufacturing went to hell...Much of the fault was the EPA restrictions on foundries. Some like Kearney & Trecker tried weldments to no avail. Then WE THE PEOPLE sat on our a&&es and let everything go off shore.

At the 1970 International Machine Tool Show in Chicago was filled with Japanese with cameras. The 1980 IMTS was filled with Japanese machine tools..great quality but not US. Now we have ChiCom junk!!!

.

.

dmort

Active member

Monarch

Very nice. I'm more than a little envious!

My old Monarch 10EE just moving it in.

It has taper, ELSR, and is the 4,000 RPM version. Came with 3 jaw Tru Adjust and a new 4 jaw, a few face plates, collet closer, and a wedge type Aloris tool post. 10EE are variable speed with a clutch. I love it even though the headstock is gawd awful long and between centers "20" is very short. Talk about heavy, smooth, and quiet. Yes, I have 2 extra sets of the very hard to find power tubes.

Very nice. I'm more than a little envious!

dmort

Active member

Leblond

We had a large Lodge and Shipley replaced with a Leblond in 67 or 68. It was a smooth running machine.

The few jobs I ran on it had more to do with swing than the length of the bed.

The Cadillac of the big lathes in the 1940-1970 period was Leblond.

After the 1970's the US machine tool manufacturing went to hell...Much of the fault was the EPA restrictions on foundries. Some like Kearney & Trecker tried weldments to no avail. Then WE THE PEOPLE sat on our a&&es and let everything go off shore.

At the 1970 International Machine Tool Show in Chicago was filled with Japanese with cameras. The 1980 IMTS was filled with Japanese machine tools..great quality but not US. Now we have ChiCom junk!!!

.

.

We had a large Lodge and Shipley replaced with a Leblond in 67 or 68. It was a smooth running machine.

The few jobs I ran on it had more to do with swing than the length of the bed.

dmort

Active member

Large machines

The table mills I ran had the horizontal and vertical controls on the spindle side of the mill.The table was deep enough to mount a steam turbine case end to end.

I have had no luck on line finding a picture let alone a brand name.

Things come back at odd times and the light might come on tonight when I get up for the second time to take a whiz. I will be sure and let you know.

You mentioned Kearney & Trecker and it rang a bell...first I thought turret lathes or maybe milling machines. Well, milling machines it was but not what I was looking for.The Cadillac of the big lathes in the 1940-1970 period was Leblond.

After the 1970's the US machine tool manufacturing went to hell...Much of the fault was the EPA restrictions on foundries. Some like Kearney & Trecker tried weldments to no avail. Then WE THE PEOPLE sat on our a&&es and let everything go off shore.

At the 1970 International Machine Tool Show in Chicago was filled with Japanese with cameras. The 1980 IMTS was filled with Japanese machine tools..great quality but not US. Now we have ChiCom junk!!!

.

.

The table mills I ran had the horizontal and vertical controls on the spindle side of the mill.The table was deep enough to mount a steam turbine case end to end.

I have had no luck on line finding a picture let alone a brand name.

Things come back at odd times and the light might come on tonight when I get up for the second time to take a whiz. I will be sure and let you know.

Last edited: