I have a little benchrest experience. Not much.

I have been following this thread with great interest. I have a 6XC and I am trying to perform some of these procedures to enhance accuracy. So far on a really good day I will get groups in the 3s. Unfortunately my reamer is cut the standard way - therefore I am opening up the necks to .264 or so and then necking back down only part way with my standard die to provide something for the bolt face to crush against. Another thing is that I am stuck with Norma brass.

Norma brass won't allow you to run very hot but you're doing the right thing in necking up/down. Strive for a tight crush on your bolt.

I like the idea of using 0000 steel wool to polish inside the necks- I am wrapping it around a nylon brush and running it into the neck with a drill. It doesn't seem to work very well. Is this the right approach?

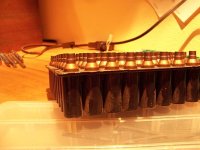

I strongly prefer spinning the case. The little drill press in the pictures cost me less than 50bucks. I wrap around a brass brush.

When you guys are talking about "clicking" - are you talking about the bolt clicking after firing a hot load? I always thought that the load was too hot when I heard that click - so I always backed off. I was afraid that I would hurt the rifle. Not true?

Clicking is the result of your case expanding to beyond it's ability to spring back. It's the result of the case sticking in the chamber either from a hot load or from a too-tight chamber. It won't really hurt the rifle but it's a pita. Backing off cures it, mostly. Keep your primary extractor cam greased. (Find this cam at the root of the bolt handle, front and top corner.

Al - I am curious- when you are talking about "tight" neck tension what do you consider "tight". .003"? .004?

Yes, .003 or .004 would be fairly "tight" for me. Beyond .003 it gets really hard to maintain linearity. I've run as tight as one can get, sizing as much as ten thou, collapsing bullets etc..... can't see any reason to go beyond .003 myself.

I am thinking about having a custom die made from Hornady without an interchangeable neck bushing because the total runout is supposed to be better.

IME runout is best controlled by minimal sizing. Size very far and nothing can help you. Don't get hung up on "straight dies" or "beefy presses" or "align-bored gobbledygook" cuz in the end the brass WILL bend to the soft/thin side you push it very far..... and there ain't NO die so far out of line so as to bend your cases...

IMO

Thanks a whole bunch to anyone willing to answer these questions!

Dirk