Update!

G'day gentlemen..

Well over the last few evenings i've managed to get the bolts started. The turning operations were completed in my lathe at home and at a much more leisurely pace than i would be at work.

I've been going over the drawings this week in preperation for the machining work and i deciding to drop the sako style bolt shroud attachment (push in and twist)and just make them thread in like a remo. This has saved me a lot of time on the machine at work and i'm not realy loosing out on anything.

Heres the pics.

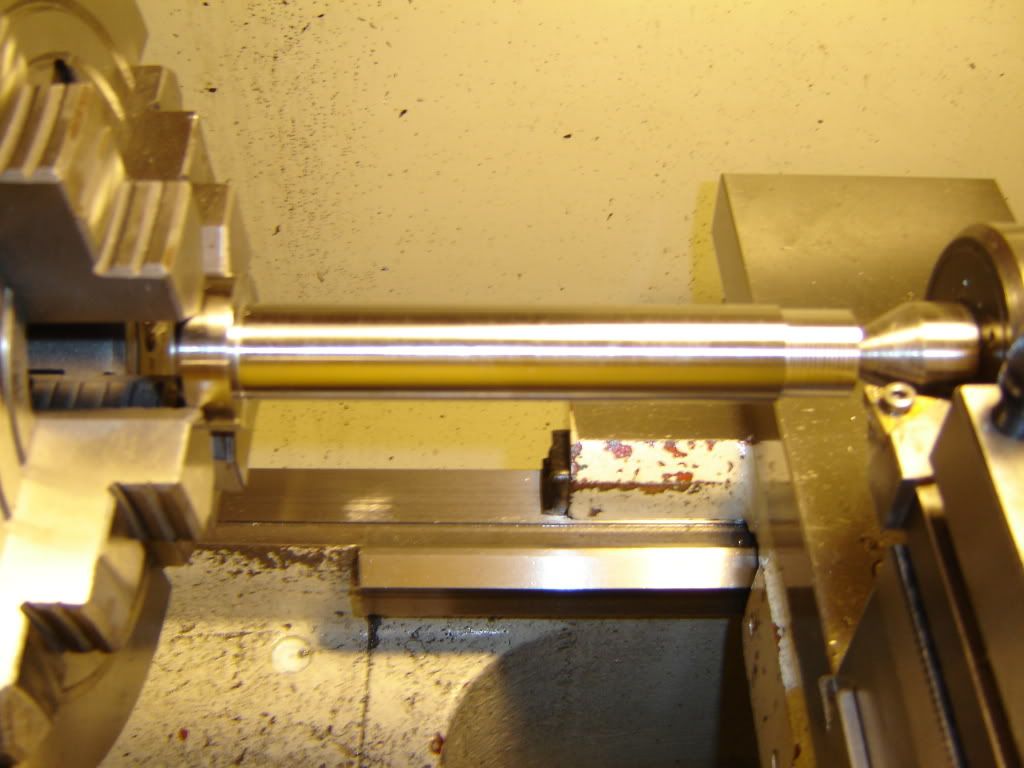

The two bolt's roughed and stress relieved.

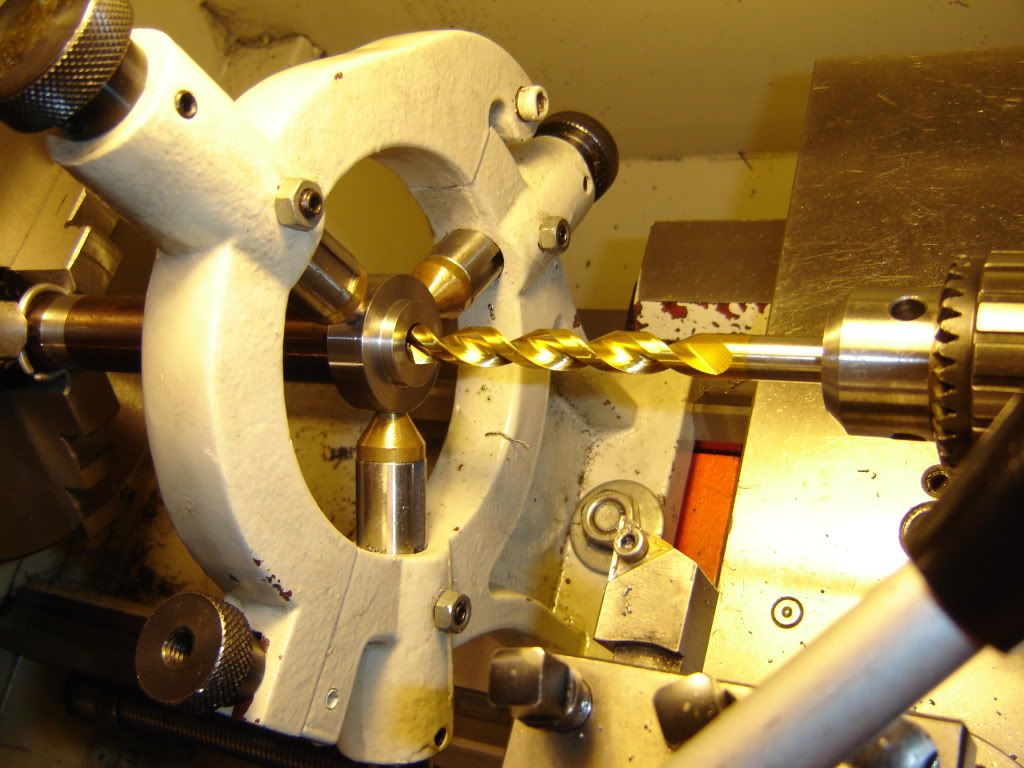

Setup for the rear of the bolt and drilling the large hole for the firing pin to 105mm deep.

Drilling the small dia hole at the end to 125mm deep.Then tapped to M12 for 30 deep.

One end finished.

Bolt was then turned arround and dialed up true and the rest of the work done in this setup.

The two bolts with the turning work finished.

Fit in the receiver was perfect!

The large flange on the end of the bolt will form the bolt handle stub. About 80% of it will be machined away leaving a cylindrical stub 10mm dia and about 6mm long which will be drilled and tapped to take a longer handle. This stub will also form a very effective safety lug on the bolt.

My next RDO is on Monday week so untill then, thats all folks..

Cheers

Leeroy