W

williev18

Guest

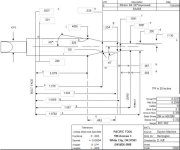

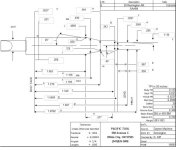

Hey guys, im looking into creating my first wild cat, and im getting ready so submit a priint to pacific tool and guage. Its going to be based on the 30RAR but with the shoulder pushed forward to 30* to go from the current 44gr water capacity to by my calculations just a wisker over 45. My problem is i dont have any fancy auto cad programs and ive done all of the math old school based on basic geometry, i was wondering if some one would look over my print to make sure my new case wall lengths coincide properly with the shoulder angle change.

any help would be appreciated.

thanks

Will

any help would be appreciated.

thanks

Will