Here's a copy of something I posted on another forum about a year ago.

The [so called] Robinett 30BR reamer - exposed.

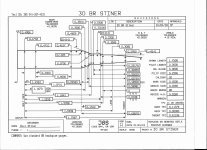

Attached is a copy (pic) of the original, and only Robinett 30 BR reamer. A reamer featuring a single alteration is not a Robinett reamer, but rather, “something else”. The only reason that my name was attached to the reamer was/is because I ordered it: at the very least, upon any alteration, my name should have been removed.

While alterations are neither necessarily bad, nor, good, they are different. When I ordered my original reamer - subsequent to, and different than Ronnie Long’s [original] reamer- I did not ask that it be proprietary, nor did I request to have my name attached/associated with copies of my dimensions: only that clones be readily available; no strings attached.

Regrettably, beyond my control, there are a multitude of reamers bearing my name, many of them, with dimensional changes which, in combination with the short/light thirty caliber bullets, are undesirable. Here are two [common] ‘deal wrecker’ attributes:

1) Excessive OAL, thus, too long a chamber neck length - typically, 1.560” (SAAMI Spec. .22 BR OAL). Mechanical neck-up processes reduce neck-length, thus OAL: 1.520” necked-up brass, in a 1.560” chamber will result in 0.040” ‘counterfeit’ free-bore.

My tooling never produces a necked-up 6mm LAPUA case in excess of 1.515” long - most are 1.512-1.513” before trimming to square the mouths. Thus, the specified maximum OAL of 1.510” on the original reamer - this has worked very well. Note: few expand-up processes/tools produce OAL greater than 1.520” - more on this later; in brief, fire-forming

does produce longer necks/OAL.

Know the OAL of your reamer/chamber.

Any amount of free-bore, especially in conjunction with #1(above). Already, #1 will all but preclude seating the short/light bullets against, or even near the lands - actual free-bore, in combination with excessive chamber-neck length [usually] spells poor results.

Short 30 caliber BR quality bullets do not require any free-bore.

Note: my original reamer features a [unusual] 1.75 degree throat angle - the typical 1.5 Deg. angle requires seating the bullet out even further! With the 1.75 Deg. throat angle, and brass trimmed only 0.010” short of filling the chamber-neck, the base of a typical short/light thirty caliber bullet, seated to contact the lands, will have only about 0.125” of shank in the case neck. Short case-necks, and free-bore erode bullet grip fast!

Not quite as bad, is a

poorly positioned, or, inadequate cone diameter (variously referred to as ‘throat’, ‘leade’, etc.):

the cone should remove every vestige of land material, preferably, at least, skimming (cleaning-up) the bottom of the grooves, affording the bullet free access to the barrel/lands. A zero free-bore reamer does just this, right off of the chamber mouth. This is not to be confused with the typical 45 degree angle at most reamer mouths, which presumably is a better chamber:barrel transition than a perpendicular wall.

There are two alterations, which, if ordering a new reamer, I would make to my original:

Diameter, at the .200” (ahead of bolt-face) DATUM line , I would state, “not less than 0.4715”.

Neck diameter 0.331”, no taper.

Note: the hand written .315 above the neck, on this print, is the approximate neck-length of my brass, when trimmed for 0.010” [length] clearance, or, when trimmed to 1.500” OAL.

I hope that this is understandable and proves useful. Keep ‘em

ON the

X! RG

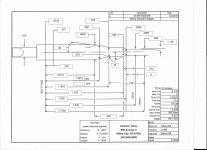

If there is any interest, I'll attempt to post a couple of GOOD chamber reamer prints - if Russ Stiner is watching, perhaps he'll help! Another very good reamer is Dwayne Pullmm's. These reamers are based upon mechanical, "necking-up" of the brass. For those who prefer fire-forming, Jackie Schmidt's method and reamer dimensions will be difficult to best.

RG

I tend to get anal regarding terminology myself - following my re-birth/survival day, a few years ago, I "mellowed out" some.

I tend to get anal regarding terminology myself - following my re-birth/survival day, a few years ago, I "mellowed out" some. As a rule, when I get involved if this argument, I accept free-bore and leade as the same difference , but consider "Throat and throating" something else, as it does, at least toward the muzzle end, have rifling, and the angle is not an entirely unimportant consideration. I can relate to the educational aspect also - way back when, one of my best supervisors ever, asked for my KTI rating -

As a rule, when I get involved if this argument, I accept free-bore and leade as the same difference , but consider "Throat and throating" something else, as it does, at least toward the muzzle end, have rifling, and the angle is not an entirely unimportant consideration. I can relate to the educational aspect also - way back when, one of my best supervisors ever, asked for my KTI rating -

RG

RG