Butch Lambert

Active member

Try Home Depot. Not a lot of info here, but a call might help you.

http://www.homedepot.com/s/copper%20ground%20rod?NCNI-5

http://www.homedepot.com/s/copper%20ground%20rod?NCNI-5

Try Home Depot. Not a lot of info here, but a call might help you.

http://www.homedepot.com/s/copper%20ground%20rod?NCNI-5

Al, I just posted links. You gonna have to do the rest.

Al,

My Home Depot no longer carries the solid copper. McMaster Carr does. If you don't do business with them, you should. Always in stock on all items I order, shipping in less than a week, 2% discount paid before 10 days, very cheap shipping, and the easiest website to navigate.

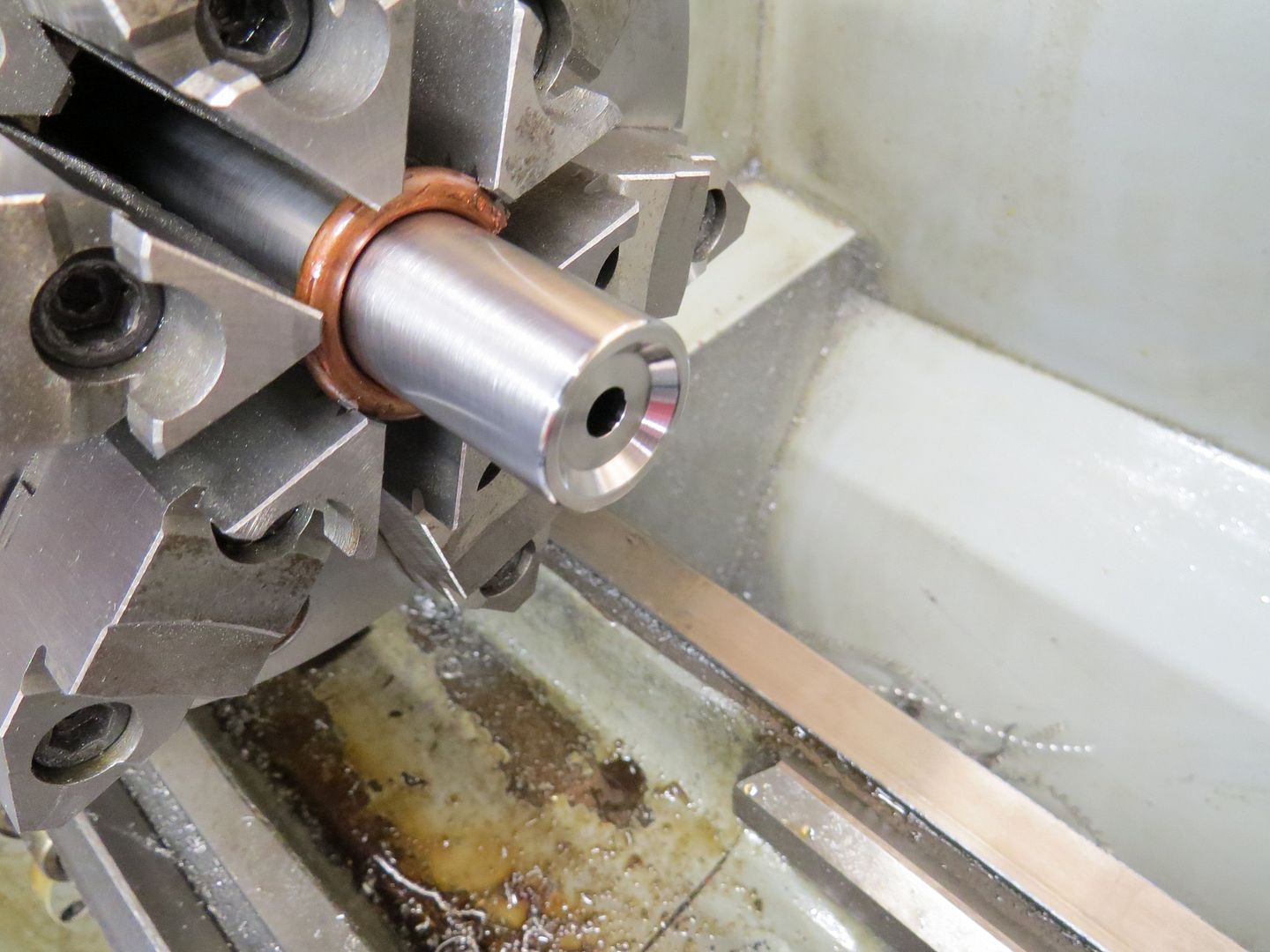

, obviously I'll never be a picture poster. I used 4 bolts with swivel pads on them, when they were tightened they lost all swivel ability. May try Nez's approach. Have used the wire approach and it works ok. This is the Chamber Flushing unit I built, and all I have to say is whyintheheckdidntyoutellmethisbefore! Works pretty darn good. My Rotary Union is on an adjustable post, just because, I use a dead mans foot switch and these chambers are beautiful.

, obviously I'll never be a picture poster. I used 4 bolts with swivel pads on them, when they were tightened they lost all swivel ability. May try Nez's approach. Have used the wire approach and it works ok. This is the Chamber Flushing unit I built, and all I have to say is whyintheheckdidntyoutellmethisbefore! Works pretty darn good. My Rotary Union is on an adjustable post, just because, I use a dead mans foot switch and these chambers are beautiful.Beauteous pic manView attachment 18754, obviously I'll never be a picture poster. I used 4 bolts with swivel pads on them, when they were tightened they lost all swivel ability. May try Nez's approach. Have used the wire approach and it works ok. This is the Chamber Flushing unit I built, and all I have to say is whyintheheckdidntyoutellmethisbefore! Works pretty darn good. My Rotary Union is on an adjustable post, just because, I use a dead mans foot switch and these chambers are beautiful.

On the manual lathe I'm a big fan of a 6 jaw set-tru type chuck with a ring of #4 copper wire between the jaws and barrel. You set the gripping pressure first and then adjust the runout. You are never fighting yourself with changing pressure on the remaining jacking screws.

I made back in '09 and used it before switching to the 6 jaw. I'll still use it when I need the absolute shortest length. I'm doing something completely different on the turning center but that's top secret.

I'm thinking about going to a 6jaw set tru like your setup, how do you like it compared to the first spider plate you made?

I'm thinking about going to a 6jaw set tru like your setup, how do you like it compared to the first spider plate you made?

I have absolutely no use for my 6jaw Set Tru check!