You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has anyone seen this?

- Thread starter Rflshootr

- Start date

jackie schmidt

New member

A couple of my friends and I had a great day at the range. Beautiful day. Windy, but beautiful.

The rifle shot great. Apparently this barrel is pretty good. I put my regular load of 29.8 grns of 133 behind a 68 grn Watson FB, (Bart’s), and the first Group after break in and fireforming eight new cases was about a .150.

I shot several other nice groups, and came to the conclusion that all I had accomplished was proving I could indeed make this gizmo, and make it work. I saw zero problems.

Does this thing have a place in extreme accuracy shooting? Probably not, for the simple reason that Gunsmiths who chamber barrels for Short Range Group or VFS already know how to chamber barrels to where all of the critical elements are truly straight with each other.

I think the market for this is in other Disciplines.Since the chamber stays on the action, brass can be used from barrel to barrel with zero hassle. Headspace remains consistent. Perhaps 600 and 1000 yard Benchrest, PRS, F Class come to mind.

Keep in mind, though, once you commit to this system, you are locked into one provider for your barrels. It’s a lot like in the old days when Gillette would give away free razors. It seemed great, a free razor. But Gillette wasn’t in the razor selling business. They were in the razor blade selling business.

I think what I am going to do with mine is set it back up and put a 6BR chamber in it. The shoulder to head is the same as a PPC, and it is also a .269 neck. For me, that makes more sense than a PPC.

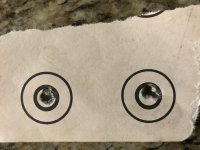

Here are the first two groups I shot this morning in some pretty stiff conditions.

http://benchrest.com/attachment.php?attachmentid=23568&stc=1&d=1588560446

The rifle shot great. Apparently this barrel is pretty good. I put my regular load of 29.8 grns of 133 behind a 68 grn Watson FB, (Bart’s), and the first Group after break in and fireforming eight new cases was about a .150.

I shot several other nice groups, and came to the conclusion that all I had accomplished was proving I could indeed make this gizmo, and make it work. I saw zero problems.

Does this thing have a place in extreme accuracy shooting? Probably not, for the simple reason that Gunsmiths who chamber barrels for Short Range Group or VFS already know how to chamber barrels to where all of the critical elements are truly straight with each other.

I think the market for this is in other Disciplines.Since the chamber stays on the action, brass can be used from barrel to barrel with zero hassle. Headspace remains consistent. Perhaps 600 and 1000 yard Benchrest, PRS, F Class come to mind.

Keep in mind, though, once you commit to this system, you are locked into one provider for your barrels. It’s a lot like in the old days when Gillette would give away free razors. It seemed great, a free razor. But Gillette wasn’t in the razor selling business. They were in the razor blade selling business.

I think what I am going to do with mine is set it back up and put a 6BR chamber in it. The shoulder to head is the same as a PPC, and it is also a .269 neck. For me, that makes more sense than a PPC.

Here are the first two groups I shot this morning in some pretty stiff conditions.

http://benchrest.com/attachment.php?attachmentid=23568&stc=1&d=1588560446

Attachments

Last edited:

BillBrawand

New member

They look good

Just shoot in yhe wind

Just shoot in yhe wind

jackie schmidt

New member

Jackie:

Very impressive! Thanks for taking the time and trouble to try out this system so the rest of us could have an independent review of how it works.

Ben, I am not sure if mine is exactly like the one Mr Dodson created, as I have no idea how he is sealing the joint where the chamber ends and the throat and lead in the barrel begins. He stated in the video that it is proprietary.I also incorporated a male fit on the barrel that goes into a female fit in the chamber adapter to insure perfect alignment.

The idea suggested by Brad in post #125 of 1/3 of the neck being in the adapter and the other 2/3 in the barrel seems to work great.

Last edited:

BillBrawand

New member

I am amazed

i am amazed at what you fellows do your knowledge and experince is an believeable and the amt of time you put into projects tought for an old farmer to keep up nice goingi decided to use part of the neck as a chamber seal. I modified my pice to where 1/3 of the neck will be part of the permanent chamber, and 2/3 will be in the barrel.

I machined the barrel tenon to where it has a male fit that fits a female fit inside the adapter. The clearance is only .0005 inch. I machined all fits to very tight tolerances, to insure alignment. That is one reason i wanted to use chrome moly, (4140) at 38 rc to insure against galling.

The inside face distance and the shoulder are exactly the same distance. I placed some prussian blue on each and seated the piece hand tight to confirm the fit.

The pictures explain a lot. It will be easy to duplicate the barrel, which i suppose is the whole purpose of this gizmo.Am going to shoot it tomorrow.

http://benchrest.com/attachment.php?attachmentid=23556&stc=1&d=1588464862

http://benchrest.com/attachment.php?attachmentid=23557&stc=1&d=1588464915

http://benchrest.com/attachment.php?attachmentid=23558&stc=1&d=1588464967

http://benchrest.com/attachment.php?attachmentid=23559&stc=1&d=1588465039

http://benchrest.com/attachment.php?attachmentid=23560&stc=1&d=1588465119

the barrel is a new 13.5 twist krieger i had.

coyotechet

Chet

Keep in mind said:Or just remove the ACE chamber system and then chamber a new barrel of your choice to the Rifle Action in the conventional way.

Chet

jackie schmidt

New member

Just wondering if folks think it's an advantage to have a perminent chamber?

Pete

For the company supplying the barrels, it’s a huge advantage.

If you go back and watch the video that started this conversation, you have to ask yourself if your barrels are suffering from the malady alluded to by the manufacturer. If not, then we are back at a solution in search of a problem.

I really wish someone out there in “Rifleland” that uses this system for a while would see this thread and chime in.

I don't find it to be useful to myself but maybe some of our firearms manufacturers might. But there also would have to be an additional cost to the end consumer I would think when all is said and done. Savage already provides a product to where the end consumer can change a barrel for him or herself. And there are after market barrels of high quality that one can also easily buy. This system appears to provide just the opposite unless I am missing something that I don't yet understand.

I don't find it to be useful to myself but maybe some of our firearms manufacturers might. But there also would have to be an additional cost to the end consumer I would think when all is said and done. Savage already provides a product to where the end consumer can change a barrel for him or herself. And there are after market barrels of high quality that one can also easily buy. This system appears to provide just the opposite unless I am missing something that I don't yet understand.

I have actions with chambers on them..... and while they're test pieces and I don't plan to sell, I could easily sell pre-fitted barrels that a child could screw on and off.....and making them is MUCH easier than correctly chambering a barrel. I developed this system for myself years ago specifically because while chambering is still "an easy machining operation" to do it my way takes time.

"My Way" means I can casually interchange cases gun-to-gun while maintaining a fit that allows me to reload a case 50-times.

I built some chambers because it took me a while to learn to actually cut individual chambers to this standard.

Especially while indexing or "timing" my barrels....

And I bought my lathe because I couldn't pay anyone else to get that sort of fit.

MilGunsmith

Member

Legality

I wonder what the legal issues are on this? Will BATF consider it a short barreled rifle with just the chamber installed?

I wonder what the legal issues are on this? Will BATF consider it a short barreled rifle with just the chamber installed?

jackie schmidt

New member

I wonder what the legal issues are on this? Will BATF consider it a short barreled rifle with just the chamber installed?

Yes it could be construed as an extremely short barreled, (or no barreled), Rifle with the barrel removed. The reason.? You could chamber a round and it would fire.

However, you would think common sense would prevail. Since a Patent has been applied for, a red flag should have been raised then about any legal issues.

But in today’s knee jerk political climate..........

Last edited:

Pete Wass

Well-known member

Thanks Al

How lmuch time would you opine can be saved when fitting a barrel by having a perminent chamber in a rifle?

Thanks,

Pete

I have actions with chambers on them..... and while they're test pieces and I don't plan to sell, I could easily sell pre-fitted barrels that a child could screw on and off.....and making them is MUCH easier than correctly chambering a barrel. I developed this system for myself years ago specifically because while chambering is still "an easy machining operation" to do it my way takes time.

"My Way" means I can casually interchange cases gun-to-gun while maintaining a fit that allows me to reload a case 50-times.

I built some chambers because it took me a while to learn to actually cut individual chambers to this standard.

Especially while indexing or "timing" my barrels....

And I bought my lathe because I couldn't pay anyone else to get that sort of fit.

How lmuch time would you opine can be saved when fitting a barrel by having a perminent chamber in a rifle?

Thanks,

Pete

How lmuch time would you opine can be saved when fitting a barrel by having a perminent chamber in a rifle?

Thanks,

Pete

2/3??? I''ve never timed myself over multiple chamberings ( some days are diamonds, some days are coal) but index/thread/throat happens so fast I'm basically done just as my psyche is getting into "go mode"

And no math, so totally relaxed.......

Shucks, jacking it in, ie indexing with just an indicator is like 10 minutes......then it takes longer to pick a bush than to cut the throat

From what I understand this is to somehow be a benefit to the majority of those who go out and buy a new firearm with this new attachment installed on it. Those folks will never change a barrel during their entire lifetime. And when handed down to the next generation they too will do the same. There are 393 million firearms that are currently owned in the US. How many of those owners could actually benefit from what is now being proposed to be the latest great thing to have ever taken place to a firearm to date.

Rubicon Prec.

New member

How lmuch time would you opine can be saved when fitting a barrel by having a perminent chamber in a rifle?

Thanks,

Pete

In the CNC world, it would save maybe 2 to 2-1/2 minutes over a full chamber and bolt nose counterbore.

In the CNC world, it would save maybe 2 to 2-1/2 minutes over a full chamber and bolt nose counterbore.

You don't index barrels, nor do you have the capacity to do identical chambers..... not even in the same sphere.

Jamming a reamer into a bore and letting it wander into place somewhere downstream isn't BR chambering, it's production work.

Rubicon Prec.

New member

You don't index barrels, nor do you have the capacity to do identical chambers..... not even in the same sphere.

Jamming a reamer into a bore and letting it wander into place somewhere downstream isn't BR chambering, it's production work.

Huh?

Are you saying you can prebore, center up and cut identical chambers in 3 minutes? Without the reamer affixed into a lathe-mounted holder?Huh?

In my experience 3-minute chambers are reamed under pressure..... if I'm wrong, please describe