jackie schmidt

New member

The patent drawings show a pressure ring. Kind of like a metal o-ring. Don't know if also helps with alignment.

Pretty crud drawings for a patent. D

Is the patent drawing on line?

The patent drawings show a pressure ring. Kind of like a metal o-ring. Don't know if also helps with alignment.

Pretty crud drawings for a patent. D

Is the patent drawing on line?

J&C check your email lemme know yea/nay

Article 4 years old. "Called" flyers. I've always called that a term used after a bad group. I guess that is kinda like the .152 group I had on the last target in New Braunfels a few years ago. I was working on a .180 teen agg. Last shot on the .152 group aided by a little shoulder made a .911 group. I went from first to 21st. Maybe I should have said it was a called flyer.

Chuckle chuckle

I meant to comment - I got a chuckle out of that as well - "The gun shoots great if you ignore the bad shots!". Still, that doesn't necessarily condemn the product - you just can't take a gunwriter's written word for anything.

GsT

That makes the best sense. No hot gas /no erosion from same.The M2HB machine gun barrels have the joint between the chamber and stellite barrel liner at the base of the neck so that the brass seals it.

That makes the best sense. No hot gas /no erosion from same.

build air riflegreat solution, but the cost would be prohibitive.

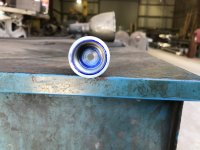

Jackie, I am sure you already know this,In the patient it talks a lot about pressure ring #40 being compressed between the ACE chamber body #20

the barrel #30. If I remember correctly, NASA used the high heat rubber as a pressure seal until it got to cold and brittle.

Chet

Why could the "ACE" not have only part of the chamber and cut throat and leade AND neck in barrel? That way the pressure would use the brass case wall to seal the joint?

Brad

View attachment 23545

My concern is brass flowing into the joint.