Rubicon Prec.

New member

Well, generally 1/10 inch of depth equals a thou of taper in my chambers so for myself, I like the gage engagement to be essentially equal between chambers. When I get a variance of say .050 in depth I can "assume" that there's at least a half-thou (5 tenths) difference....but definitely A DIFFERENCE.....

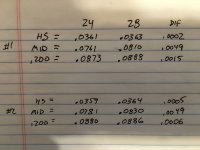

OK, I made a quick [approx] .200” datum gauge. I pulled two barrels from my barreled actions. I measured HS, the approx midway body point and the approx .200 point. The gauges don’t sit perfect in the tapered chamber so I understand there is error. I ran the measurements twice to get a better average. The mid point gauge had about a .005” depth difference between the two random chambers. HS was about .0005” (may or may not have been intentional, these chambers were for different actions). The .200” point had maybe .002” depth difference. I’m no math magician, but it’s looking to me like the chambers are pretty close to “identical”. I’m pretty confident that brass from these two barreled actions would easily interchange.

This test is certainly not scientific, and I still will not guarantee a .00025” dimension on anything. I will say that I feel my chambers are as dimensionally accurate as any. You turn knobs, and there’s nothing wrong with that. I have servos instead of knobs. The work is the same.