Don’t even think of trying to follow the instructions on the bottle and applying tru-oil with your finger or a “clean rag” unless it's going on your ole huntin rifle or a Garand. If it is a “new rifle” look that you're wanting, nothing short of a pro spray gun will deliver the effect. I went through a lot of grief discovering this the hard way.

I bought a used 3” wide Richard’s Micro thumbhole stock on eBay about 3 months ago. I opened the barrel channel, rounded off the old fashioned sharp triangular forend, and stripped off all of the old finish, sanded and restained it.

But by far the most frustrating and time consuming process over the last 3 months of this on-and-off work was trying to properly apply the tru-oil into a smooth clear-as- glass gloss finish. Each time the tru oil went on improperly, some damage to the stained finish was inevitable as I had to sand the tru-oil back down into the stain. I literally had applied about 10 tru oil finishes before I finally figured out how to get it on right with a spray gun and finally finished the thing today. Hellalujah. I might actually get to fire this 22x47L rifle after waiting over a year. Sheeesh.....

I finally reverted back to my better instincts from when I use to build and spray paint my R/C airplanes. I don’t know why I thought it would be any different with tru oil, being it mixes and sprays not much differently then traditional enamel oil paints like Rustoleum.

Yes....I know its sold in an earosol can too. But I'd rely on that to deliver professional results the same way that a custom bike or auto shop would use Krylon. (...not)

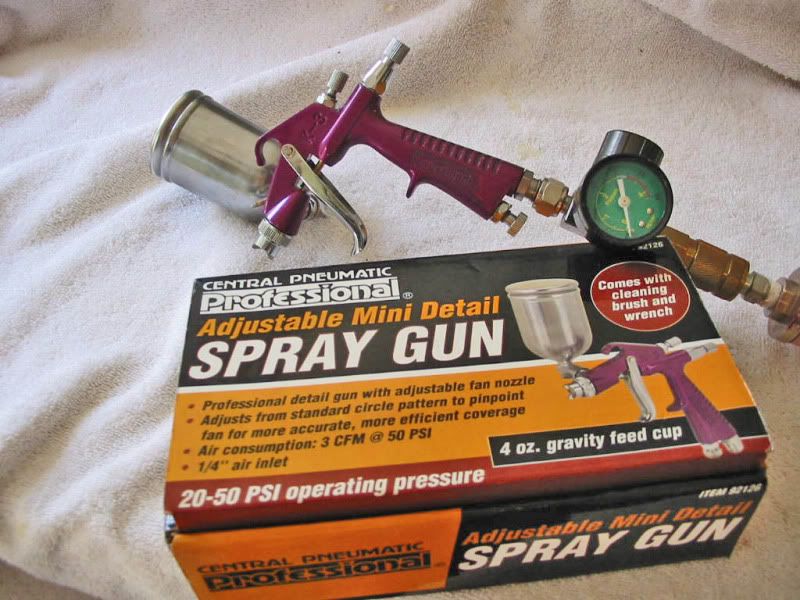

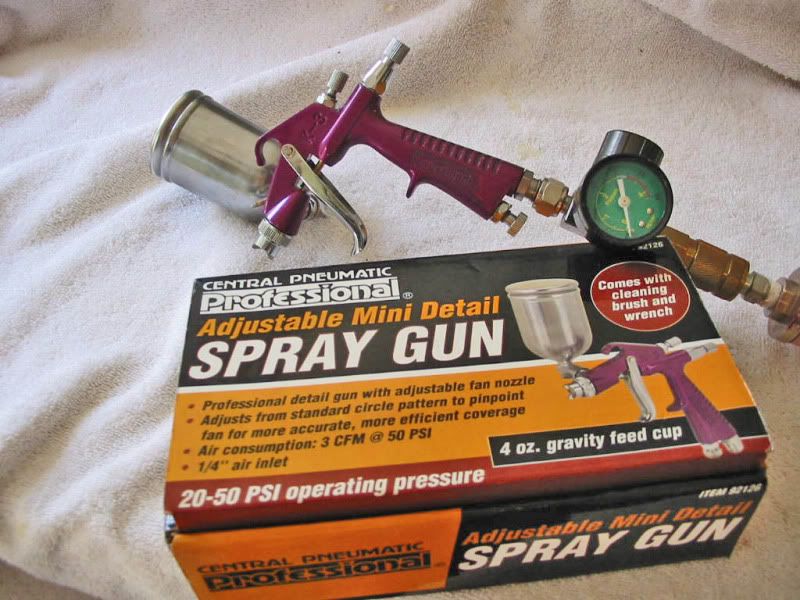

If you have an air compressor, then you’re more then halfway there. Buy a Harbor Freight detail spray gun, model # 9216-2VGA. It’s an unbelievable buy at $10 on the internet (it cost me $15 in the store) It does NOT come with the gage.

I bought a used 3” wide Richard’s Micro thumbhole stock on eBay about 3 months ago. I opened the barrel channel, rounded off the old fashioned sharp triangular forend, and stripped off all of the old finish, sanded and restained it.

But by far the most frustrating and time consuming process over the last 3 months of this on-and-off work was trying to properly apply the tru-oil into a smooth clear-as- glass gloss finish. Each time the tru oil went on improperly, some damage to the stained finish was inevitable as I had to sand the tru-oil back down into the stain. I literally had applied about 10 tru oil finishes before I finally figured out how to get it on right with a spray gun and finally finished the thing today. Hellalujah. I might actually get to fire this 22x47L rifle after waiting over a year. Sheeesh.....

I finally reverted back to my better instincts from when I use to build and spray paint my R/C airplanes. I don’t know why I thought it would be any different with tru oil, being it mixes and sprays not much differently then traditional enamel oil paints like Rustoleum.

Yes....I know its sold in an earosol can too. But I'd rely on that to deliver professional results the same way that a custom bike or auto shop would use Krylon. (...not)

If you have an air compressor, then you’re more then halfway there. Buy a Harbor Freight detail spray gun, model # 9216-2VGA. It’s an unbelievable buy at $10 on the internet (it cost me $15 in the store) It does NOT come with the gage.