You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

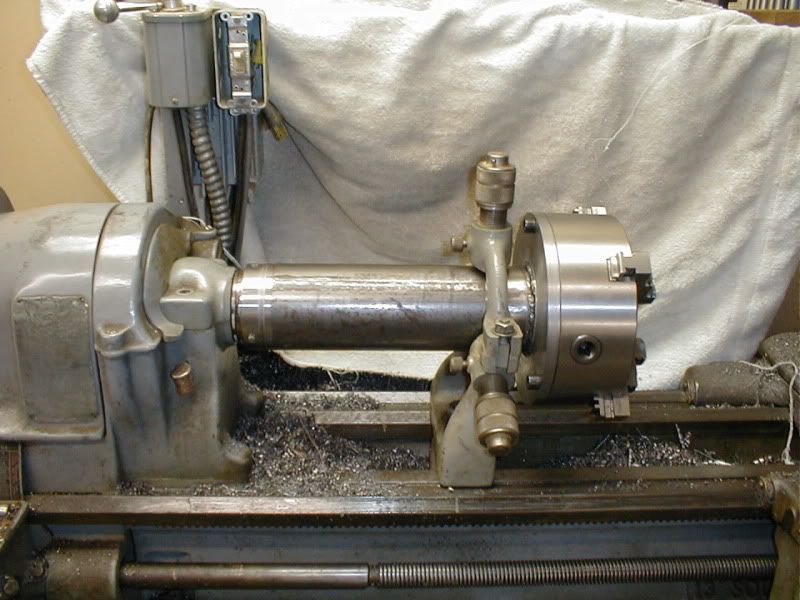

Spindle hole too small to chamber through? Here's an idea....

- Thread starter RoyB

- Start date

C

Cheechako

Guest

I like it! I don't need one but I may make it anyway.

BTW, what is the big oil cup under the bearing? What does it lubricate?

Ray

BTW, what is the big oil cup under the bearing? What does it lubricate?

Ray

John Kielly

Shari's fan club

Bout time somebody cleaned up some swarf!

JerrySharrett

Senile Member

I fail to get your point. I can see that is a South Bend. looks like a early Heavy 10??. It has the spindle capacity to do most benchrest diameter barrels.

I can see the ways might be worn near the spindle. What does this have to do with doing barrel fitting?? Even worn ways will not inhibit turning and threading a barrel tenon, even a Stolle Teddy which is about 1 3/8" long.

How would you align the left end of the barrel with that rig?

How would you dial in the chamber with with that rig?

I'm missing something here.

Nice pictures tough.

I can see the ways might be worn near the spindle. What does this have to do with doing barrel fitting?? Even worn ways will not inhibit turning and threading a barrel tenon, even a Stolle Teddy which is about 1 3/8" long.

How would you align the left end of the barrel with that rig?

How would you dial in the chamber with with that rig?

I'm missing something here.

Nice pictures tough.

JerrySharrett

Senile Member

Ray, that big oil cup lubricates the front spindle bushing. There is one just like it on the rear bushing. This lathe doesn't have spindle bearings. That is what makes them so rigid.BTW, what is the big oil cup under the bearing? What does it lubricate?

Ray

JerrySharrett

Senile Member

Caution

Whoever owns that rig better pay up their life insurance. I just zoomed that top picture and the weld is broken just behind that chuck flange plate!!!!!!!!!!!!!!!!!!!!!

Whoever owns that rig better pay up their life insurance. I just zoomed that top picture and the weld is broken just behind that chuck flange plate!!!!!!!!!!!!!!!!!!!!!

C

Cheechako

Guest

Ray, that big oil cup lubricates the front spindle bushing. There is one just like it on the rear bushing. This lathe doesn't have spindle bearings. That is what makes them so rigid.

Jerry - Yeah I figured it had a bushing rather a bearing, but the cup seemed too low. It must be a big busing.

Ray

It's not my lathe, so I have no idea about the oil cup. I saw this on another forum I frequent.

Good catch, it sure does look cracked! I would have just threaded the extension for a threaded back plate...........

I just zoomed that top picture and the weld is broken just behind that chuck flange plate!!!!!!!!!!!!!!!!!!!!!

Good catch, it sure does look cracked! I would have just threaded the extension for a threaded back plate...........

T

TRA

Guest

Personally, I see a lot of future in that 1st photo. Look at it for a while and think, let's see if y'all can see it. It should be a light bulb to some of you.

JerrySharrett

Senile Member

Actually there are 3 pipe threaded holes on each spindle bearing reservoir.

The oil cup is supposed to go in the center hole.

The oil cup is supposed to go in the center hole.

F

frwillia

Guest

It's not my lathe, so I have no idea about the oil cup. I saw this on another forum I frequent.

Good catch, it sure does look cracked! I would have just threaded the extension for a threaded back plate...........

The other fun thing is the electrical switch with no cover plate where chips can be flung into it if the chuck is on the headstock. Last time I checked, metal swarf conducts electricity. That could put the thrill back into using that lathe.

Fitch

Pete Wass

Well-known member

Only on Newer Models

Many, Many of the older ones have ony the oilers; no pipe plugs. Some of the real old South Bends had a small oiler on top of the cap. There are also machines that have a metering oiler on top that has a glass resovoir.

Anyone interested can go to the Practical Machinist Site and visit the South Bend Forum. There is a wealth of interesting information on there.

Many, Many of the older ones have ony the oilers; no pipe plugs. Some of the real old South Bends had a small oiler on top of the cap. There are also machines that have a metering oiler on top that has a glass resovoir.

Anyone interested can go to the Practical Machinist Site and visit the South Bend Forum. There is a wealth of interesting information on there.

JerrySharrett

Senile Member

How is this any better than just using the steady rest on a trued collar/spider on the barrel? Maybe I'm just set in my ways because my lathe won't fit a blank through the headstock.

Regards, Ron

The setup pictured looks like it was made for a special job. It wouldn't be worth crap for chambering, IMO. For example, no way to line up the other end of the barrel and the chuck is a 4-jaw universal with no way to adjust it for runout.

Jerry,

No one suggested this was set up for gunsmithing.....

But IF you had a spider on the outboard side and IF you were threading a tapered barrel that would fit into the limited bore of your headstock and IF the chamber end of the barrel was to large to fit into the headstock and IF you made this device quite a bit shorter because you don't need it this long and IF you decided to use a Tru-Adjust chuck or a real 4-Jaw and IF you did all of this because you wanted the extra mass around the area you are chambering for less vibration and a better cut and IF you went through all this work because you cut better chambers and cut better threads................Then it just might be a good idea...No?

No one suggested this was set up for gunsmithing.....

But IF you had a spider on the outboard side and IF you were threading a tapered barrel that would fit into the limited bore of your headstock and IF the chamber end of the barrel was to large to fit into the headstock and IF you made this device quite a bit shorter because you don't need it this long and IF you decided to use a Tru-Adjust chuck or a real 4-Jaw and IF you did all of this because you wanted the extra mass around the area you are chambering for less vibration and a better cut and IF you went through all this work because you cut better chambers and cut better threads................Then it just might be a good idea...No?

W

Wildcatter

Guest

Too many IFs. Or not enough. You forgot the one about IF a frog had wings.

Operative word here is "idea"..........Not a solution, but something to expand upon......Something to use your imagination with......being a machinist one has to think outside the box. Rarely does someone bring you a full baked solution......if they did, you wouldn't be a machinist, you would be a machine operator.

Now everybody just lighten up........the snow will melt and this cabin fever will subside...

Now everybody just lighten up........the snow will melt and this cabin fever will subside...

JerrySharrett

Senile Member

Now everybody just lighten up........the snow will melt and this cabin fever will subside...

Snow, what snow? We were 58F today and looking at a forecast 65 tomorrow......finally!!