Rubicon Prec.

New member

This is Robert. Don’t be like Robert...

This is a personal project so at least I’m not buying a customer a barrel. This barrel is 1.375 for 5” then tapering to 1.010” at 32” and I have a second one. Losing 1-1/4” on the chamber end isn’t really going to be the end of the world for me.

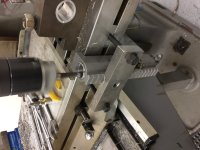

So, the threads were not too tight and the barrel had already been screwed on/off hand tight several times during the machining process. I knew it was going to be a while before I could finish this project so I washed the barrel and receiver with hot water and Dawn and dried. A little while later I was sitting in my office (probably after a few cocktails) looking at the barrel, receiver, bottom metal and stock. I figured I’d screw the barrel on by hand and toss it in the stock to see what it will look like. Well, the dry barrel screwed in just fine....until it didn’t. I heard squeak, and it got tight. Tried backing it off and it only went about 1/4 turn. I immediately soaked it with penetrating oil and tried to back it off again. No joy. I knew at this point the receiver would be destroyed if I tried to use tools to unscrew it. It was time to sacrifice a bit of barrel and hope the receiver is OK.

After the tenon was extracted, the receiver looks pretty good. Just one tiny nick on a thread. This receiver is too tall to fixture in my CNC mill otherwise I’d chase the threads with a threadmill. I’ll probably just run a tap down it to clean it up.

Moral of the story, ALWAYS lube your threads!

This is a personal project so at least I’m not buying a customer a barrel. This barrel is 1.375 for 5” then tapering to 1.010” at 32” and I have a second one. Losing 1-1/4” on the chamber end isn’t really going to be the end of the world for me.

So, the threads were not too tight and the barrel had already been screwed on/off hand tight several times during the machining process. I knew it was going to be a while before I could finish this project so I washed the barrel and receiver with hot water and Dawn and dried. A little while later I was sitting in my office (probably after a few cocktails) looking at the barrel, receiver, bottom metal and stock. I figured I’d screw the barrel on by hand and toss it in the stock to see what it will look like. Well, the dry barrel screwed in just fine....until it didn’t. I heard squeak, and it got tight. Tried backing it off and it only went about 1/4 turn. I immediately soaked it with penetrating oil and tried to back it off again. No joy. I knew at this point the receiver would be destroyed if I tried to use tools to unscrew it. It was time to sacrifice a bit of barrel and hope the receiver is OK.

After the tenon was extracted, the receiver looks pretty good. Just one tiny nick on a thread. This receiver is too tall to fixture in my CNC mill otherwise I’d chase the threads with a threadmill. I’ll probably just run a tap down it to clean it up.

Moral of the story, ALWAYS lube your threads!

Attachments

-

30FBFF86-6134-4310-A3E5-5FA661970CC3.jpeg1.3 MB · Views: 484

30FBFF86-6134-4310-A3E5-5FA661970CC3.jpeg1.3 MB · Views: 484 -

179BB8EF-CA8B-4338-91BD-B73570F8CA3A.jpeg1.7 MB · Views: 424

179BB8EF-CA8B-4338-91BD-B73570F8CA3A.jpeg1.7 MB · Views: 424 -

E4E74344-10F5-4E2A-B3BF-E198929804C8.jpeg1.7 MB · Views: 427

E4E74344-10F5-4E2A-B3BF-E198929804C8.jpeg1.7 MB · Views: 427 -

C3B24598-4BB1-413B-A575-EB2B6F7FE6CB.jpeg1.5 MB · Views: 406

C3B24598-4BB1-413B-A575-EB2B6F7FE6CB.jpeg1.5 MB · Views: 406 -

9A08BD9D-5EA6-44D9-921F-0E7C2588A011.jpeg1.6 MB · Views: 377

9A08BD9D-5EA6-44D9-921F-0E7C2588A011.jpeg1.6 MB · Views: 377 -

1A91B3FC-C1BC-4094-BC5E-E61E4C341E68.jpeg1.5 MB · Views: 404

1A91B3FC-C1BC-4094-BC5E-E61E4C341E68.jpeg1.5 MB · Views: 404