Boyd Allen

Active member

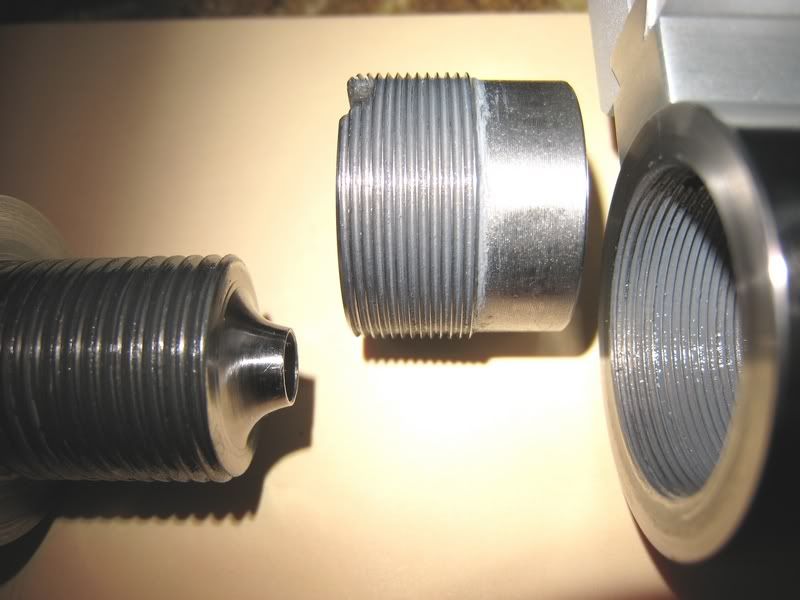

I have no idea of what you mean by straight threads. Also, Gene Beggs solved the indexing thing, at least for cartridges of .223 head diameter, "all" that would need be done for larger diameter cases is to build an action with a large enough front receiver ring to accommodate barrels normal shanks with an intermediate bushing between tenons and the receiver. If you are unfamiliar with how he did it, you might do a little searching.