Good morning Tony:

All of this happened in the first few years of my sponsorship (around 2011 I think), so to answer your question - no, I did not run any testing with Eley (or any other manufacturers ammunition). I have to believe that it would make a difference though, just based on what I saw initially and in all the barrels / seasons since.

From memory, I ran the initial testing with two older Hart barrels I horded (that were six groove .2170 / .2220 barrels). Since I have retested with everything I had - Benchmarks, Kriegers, Shilens (Octagons and Ratchets) and a very few Muller 8 groove blanks. Although the engagement depth preferences varied slightly, there has always been a "sweet spot" where group size and vertical dispersion leveled out, and that accuracy was maintained through 200+ rounds without cleaning (I don't like cleaning between individual matches at our events).

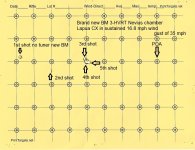

And I have never tried to establish a dimension from the datum (the .660" you mentioned) - when chambering, I use a number of live rounds, cleaned of lubrication, very gently seated against the leade until you can feel them make a hard stop. I then measure what Jerry calls the "stickout", or the distance from the back of the cartridge to the tennon datum face. That dimension minus headspace gives you engagement depth. I currently use the same setup found in the initial testing I ran of .0780 (minus .0430 HS) for an engagement depth of .0350 approx. Lapua ammunition is amazingly consistent round to round, and you would be amazed how repeatable this dimension is between rounds. Lead is soft, so I don't use the same round twice during verification (just in case there is a small amount of deformity). You can definitely feel a hard stop as the round seats against the leade.

Although I have never run this testing with Eley, I do have a "standard" Eley chamber I use (I shot Eley in competition my entire career prior to 2008, and was doing my own smithing at that time too). The chamber setup I use for Eley engraves with a "stickout" dimension of approximately .1360 (approx. .0930 engraving). I say approximately because I have found Eley far less repeatable round to round regarding the distance to the driving band. That's not a knock on Eley (we all know it shoots exceptionally well), it just doesn't allow measurement in this way without some bracketing. Just wanted to share what I was doing for Eley on the rare occasion I do a barrel for it. BTW.....Lapua in the same chamber engraves to a "stickout" depth of .1170 (Lapua's driving band position is shorter / smaller than that of EPS, about .0190).

I have tried a million chamber finishing methods - mandrels, lapping compounds, you name it. In the end (and please, this is only my opinion) I just couldn't justify putting anything even mildly abrasive in a chamber I have tried so hard through the machining process to be dimensionally perfect and concentric. So I have concentrated on speeds / feeds and lubrication to try to machine the most clean / smooth and burr free chambers I can - and let the round count do the rest. If you are interested, I use JGS carbide reamers, at 180rpm, fed exceptionally slow (cleaning chips every .100, and .030 on the last pass) with the older (non EPA compliant) tap magic fluid. Not sure what is in that stuff, but it cuts exceptionally clean chambers with sharp tools. I chamber in a steady rest from the tailstock. There are a million ways to do it, and again, not saying this is the best way (it's just the best way I've found, for my equipment).

I hope I answered your questions, thanks for the reply,

kev