Jay Cutright

New member

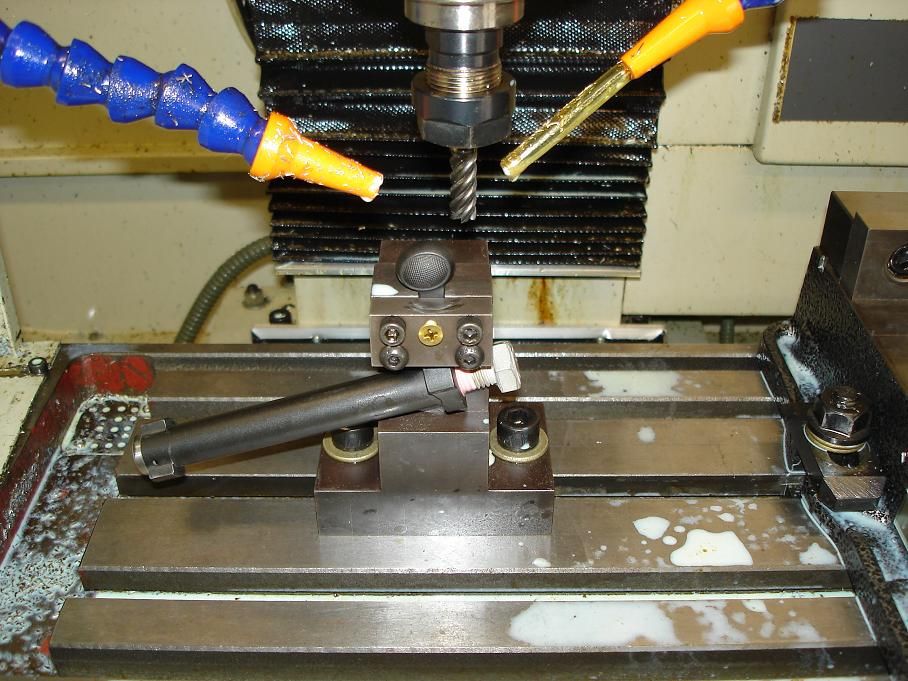

I started threading handles for my tactical minded customers and long range hunters were wanting them too.

It seems like they always want a badger ordnance knob but I don't like buying that stuff just to have in stock so I made some.

The one on the left has all the same dimensions as badgers knob except the contour is different, mine has a straight taper instead of the rounded contour like the badger. The one on the right is a scaled down version I'm thinking about making more of maybe even smaller in diameter than the one shown. These are both in Armor black Cerakote ready to install.

It seems like they always want a badger ordnance knob but I don't like buying that stuff just to have in stock so I made some.

The one on the left has all the same dimensions as badgers knob except the contour is different, mine has a straight taper instead of the rounded contour like the badger. The one on the right is a scaled down version I'm thinking about making more of maybe even smaller in diameter than the one shown. These are both in Armor black Cerakote ready to install.