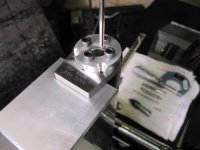

I have installed two piece bases true on out of true actions by using a good set of machined rings mounted on a precision shaft to hold things in alignment while bedding the bases.

After dry assembling everything I remove the bases, epoxy, just start the screws and remount the rings and shaft to hold everything in alignment while the epoxy sets up. Then disassemble remove clean and reinstall screws. It has worked very well but is kind of fussy to deal with.

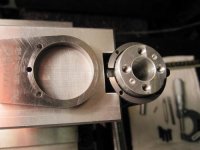

So being that I love to design tools I drew up a tool that would hold two piece bases in alignment and allow access to the screws during bedding, but before I built it I found an almost identical tool to what I had in mind here.

http://www.basebed.com/

I haven’t purchased or used yet but I agree with the concept as long as the machining is precise.

With one piece bases it’s cake.

Bob