D

david dumas

Guest

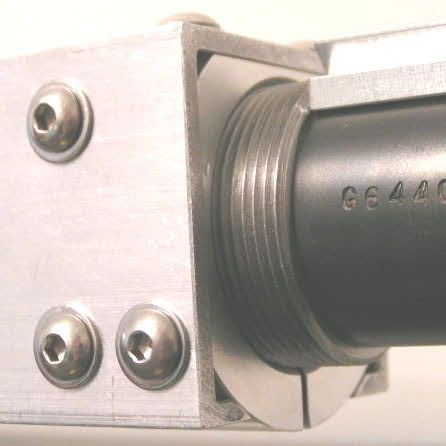

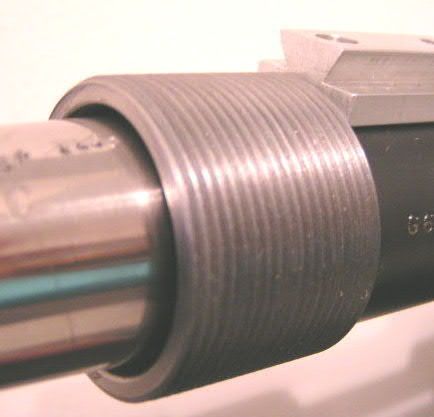

Barrel nut, floating bolt head and shims.

Adrian "The Savage King" Van Gorder

Hey man, we may fight over that "savage king" title,,,,,,,,,,,,,,,,,,,,

the wind is my friend,,,,,,,,,,,,,,,,,

DD

Barrel nut, floating bolt head and shims.

Adrian "The Savage King" Van Gorder

If you look at the frequencies of the first mode and at the velocity points that you come into tune, they dont correlate. It has to be a higher frequency mode.

it is not as simple as the barrel only moving in one direction and at one frequency and getting the bore curvature lined up.

My point here thought is that a properly aligned barrel does not need to be indexed in the first place!!

Gene, you never did answer as to how this "needs indexing" barrel was aligned for chambering. And, I strongly disagree that only one in twenty barrels are Top-5 competitive. Tony keeps more than that and he is probably the most demanding shooter I know......except a certain shooter named Jack.

An answer to this problem could be a sleeve with a thread matching the barrel shank (presumeably right hand thread) and threaded with a left hand thread of the same pitch (threads per inch) on the outside. (With a matching LH thread inside the action). The sleeve would need a Hex Head and locking nut. As the barrel is rotated the sleeve would have to be rotated in the opposite direction...exactly the same amount. This would maintain headspace and allow rotation of the barrel relative to the action BUT whether it would be a practical set up on the range I am not sure. Herbit ...New Zealand

Could this be a simple threaded adaptor, with a right hand outside thread, left hand inside thread, and a left hand barrel tenon?

As far as holding the bushing, it would be a slight tight fit on the barrel tenon, rotatable with a wrench, perhaps pliars. Being the threads would counter each other, there would not be a great urge for the bushing to rotate while tightening.

use a differential thread. Have an in between piece that threads into the action with different threads in the barrel. That way if you turn the barrel .25 turn in, move this same amount out and it gives the same headspace, just a different barrel index spot.

Have you ever stopped to think that all of this effort is based on a false premis that you mistakedy stated as fact in your unitial post??..........jackie

Gene

How about putting a 2 to 1 ratio on your bushing? 16 thread action 32 thread for the barrel. Move bushing a 45 degree for every 90 degree you want to change the barrel. Bushing .0078 out (45º) and barrel .0078 in.(90º)

Glenn

My question is, " How many of our top gunsmiths have experimented with indexing and what results did they get?" Good shooting....James