I agree that this looks like it is an infomercial but it is just a follow up on some testing I did in Aug., as well as its relation to an article Dan Lilja did in last months NBRSA Precision Rifleman magazine about barrel length vs. rigidity. I will scan the article and if anyone who does not receive the NBRSA Precision Rifleman magazine would like a copy, you may email me at

speedy.godzilla@msn.com and I will be happy to email a copy to you in the evening when I sit down and answer emails.

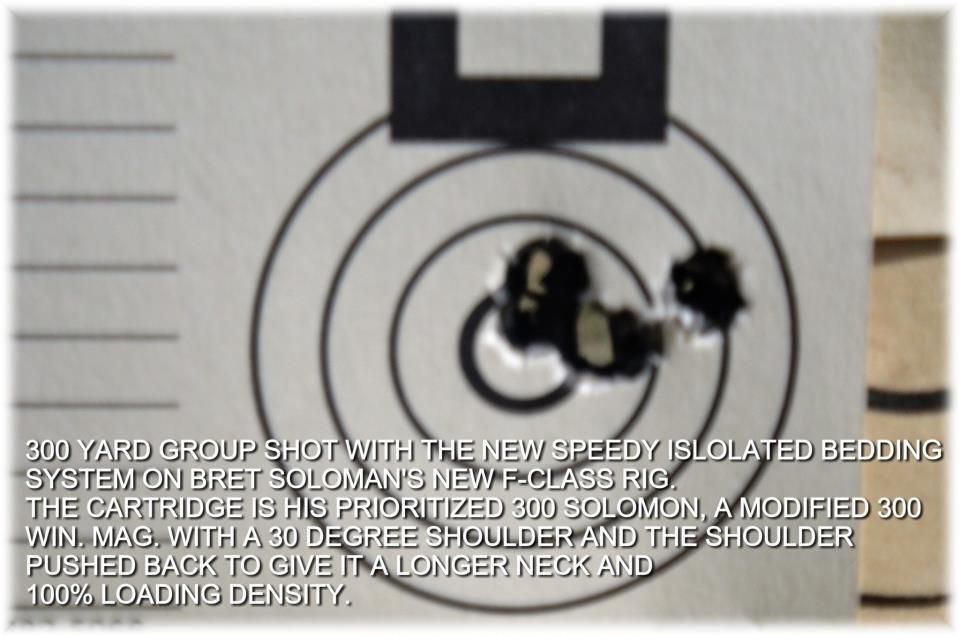

What led to the the "Isolation" Bedding system was a test we conducted in August of this year as I said earlier. We have noticed and have heard back from competitors about their inability to minimized vertical dispersion at long range even though they have very low standard deviation on their loads. I took a 284 Winchester F-Class rig I had just finished up out to the Whittington Center and developed a load with the customer that delivered sub 1/4 MOA and had a STD deviation of only 3 FPS. While shooting the rifle I became aware of the springboard effect that is typical to most modern F-Class rigs with their long forearm stocks and the 28" plus long barrels. We shot the rig at 1000 yards in relatively calm conditions for Raton, N.M. and though we were able to hold the X-Ring I felt that is was with some difficulty, with some shots being marginal X's almost 10's. I was curious if the stock designs with their long forearms and long heavy barrels might be contributing to some of the vertical manifesting itself on the target?

At lunch we drove back to Trinidad and retrieved my rail gun and replace my PPC barreled action with the Bat chambered in 284 Win. and sighted her in for 1000 yards. Rather than let the rail return to battery every time, we moved it off target and then repositioned it with the windage and elevation controls for each shot to more closely mimic returning a shoulder fired rifle. The conditions at Raton were in our favor that day and remained pretty constant until about 6:00 when evening showers threatened.

We we surprised to find that the vertical in the X-Ring was cut almost in half for three 10 round strings and almost by 3/4 in the on string we fired with the rail returning on its own to establish a benchmark for comparison.

What the rail did was establish a more rigid platform and in a sense shorten the barrel by about 6" making it more rigid as well. Two days later I received my Precision Rifleman magazine and low and behold there is an article by Dan Lilja writing about what we had just tested and confirming some of what we had just tested. The "Gimmick" if you wish to call it that, was simply the results of our tests and the article by Dan to test the theory in actual application and see if there is any validity to building a set-up similar to the physics of a rail that can be employed in a bag gun and further develop long range platforms that are capable of taking advantage of of a cartridges true accuracy potential.

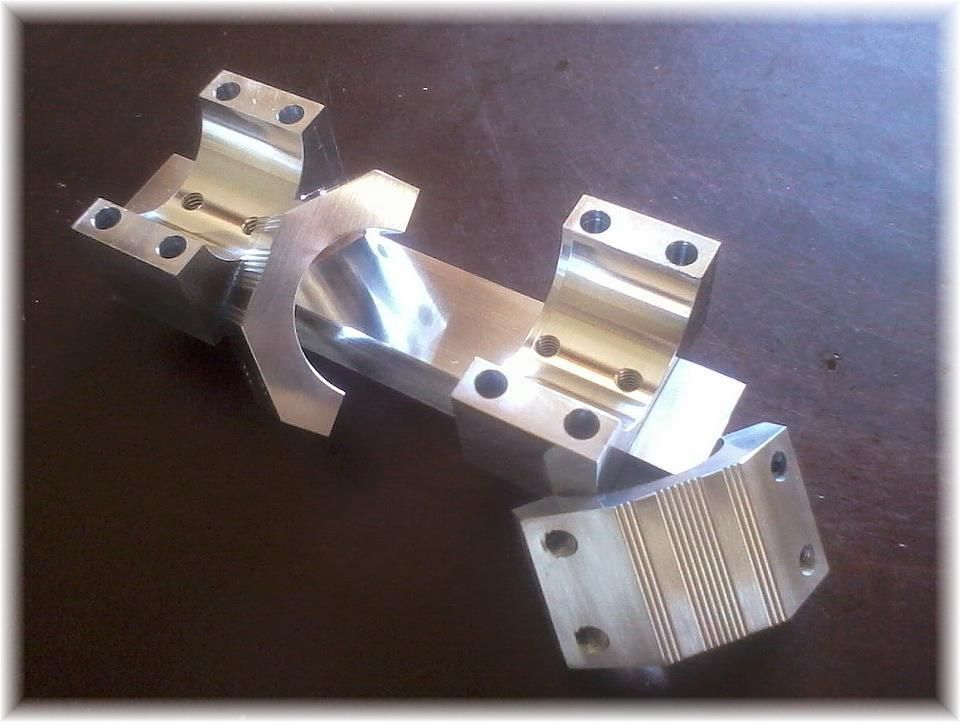

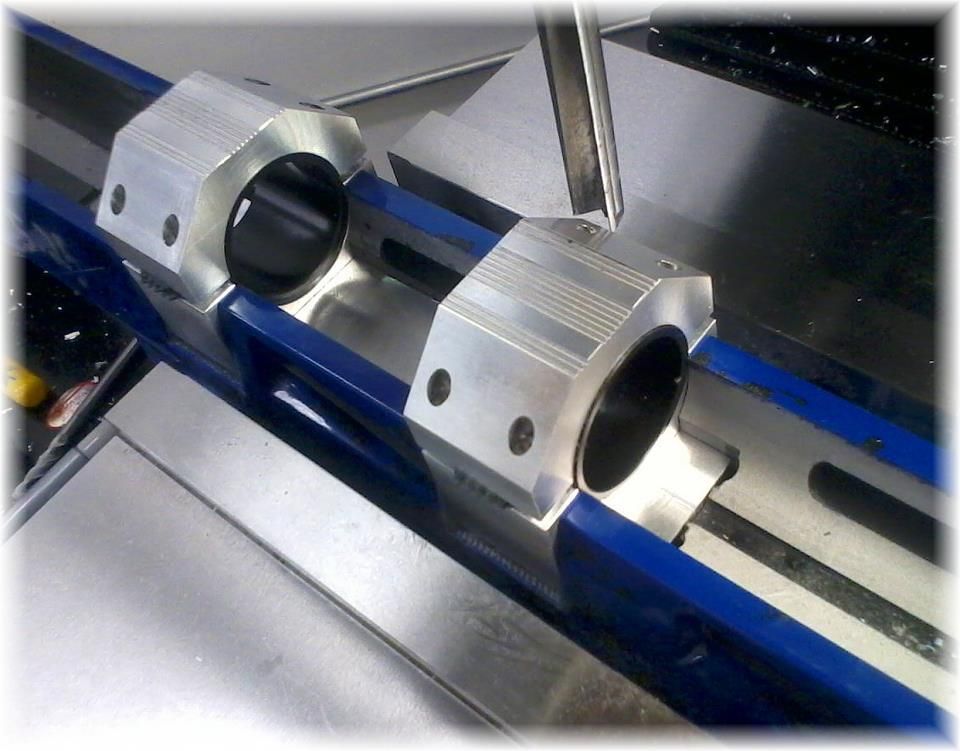

We call this system an "Isolated" bedding system because we wish to isolate the barrel harmonics and heat transfer to the clamping pillars through the use of polymer inserts machined to fit the barrel and clamps within 0.0005. Seeing how the clamping pillars are made from 7050 T-7 aluminum and aluminum has 2 1/2 time the expansion ratio of steel we did not wish to transfer heat to the system and have it move or shift on us mid string.

The stock is a Robertson FX-1000 of my design that can be purchased through Jerry Stiller at viperactions.com , it is of carbon fiber / fiber glass design with a rigid foam core. I now T-Slot a 1/8" carbon fiber sheet into the forward tunnel of the stock and then add one or two vertical members to the inside of the stock forming a T or an H depending if the barrel has taper or is a straight cylinder. The action is completely free floated which would allow shooters to use one stock and multiple barrel and action configurations.

I will continue to post as we do more testing.

Speedy Gonzalez