D

dennisinaz

Guest

just don't do what I did

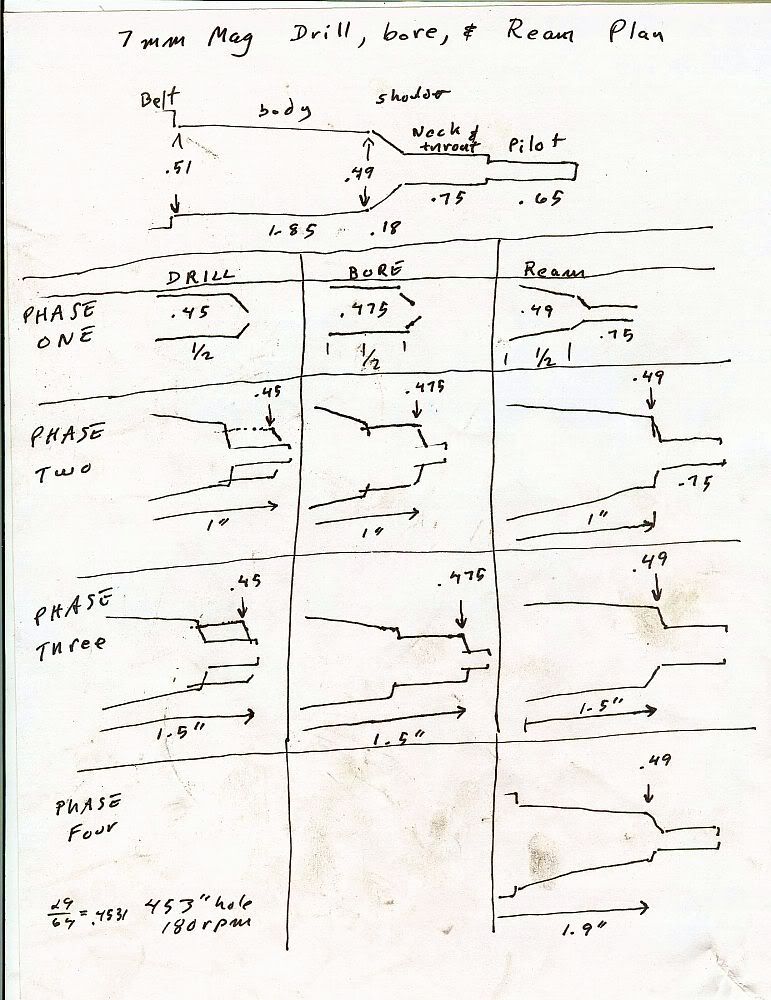

I did my first chamber today with the pre-bore method. I made paint mark on the 29/64th so I would know where to stop. That went fine. I then set up a taper with my compound and started cleaning up the hole. That went fine too until I went to take my last spring pass. I must have bumped the crossfeed handle because as I started feeding the boring bar in I realized that it was taking off more than it should have. I stopped and hoped that it could clean up with the reamer..

It didn't- the last .08 or so is oversize and looks like heck. The rest of the chamber is mirror smooth. Be careful not to take to much out!!!

Not sure the best way to check progress when boring a tapered hole. Live and learn I guess.

I did my first chamber today with the pre-bore method. I made paint mark on the 29/64th so I would know where to stop. That went fine. I then set up a taper with my compound and started cleaning up the hole. That went fine too until I went to take my last spring pass. I must have bumped the crossfeed handle because as I started feeding the boring bar in I realized that it was taking off more than it should have. I stopped and hoped that it could clean up with the reamer..

It didn't- the last .08 or so is oversize and looks like heck. The rest of the chamber is mirror smooth. Be careful not to take to much out!!!

Not sure the best way to check progress when boring a tapered hole. Live and learn I guess.