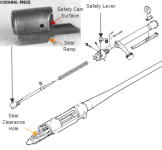

Maybe the following diagram will help to identify the critical fit areas:

With the safety lever in the forward "fire" position, lifting the bolt handle rotates the bolt and the nose of the cocking piece will cam the cocking piece back compressing the firing pin spring, cocking the firing pin assembly and allowing the sear boss up through the sear clearance hole. When the bolt is rotated down to locked position, the firing pin assembly moves slightly forward until the sear ramp on the cocking piece engages the sear boss from the trigger which then restrains the firing pin.

From this cocked and locked condition, the safety is engaged by rotating the lever to the rear. A cam below the safety lever engages the safety cam surface of the cocking piece transferring the holding function from the trigger sear to the safety cam. The mid position holds the firing pin but allows the bolt to be rotated and removed while the rear position locks the firing pin assembly to the bolt via a locking pin that prevents bolt rotation and removal.

If the safety lever can not be rotated to the rear with the bolt mechanism in the cocked and locked position but the firing pin can be released using the trigger, the most likely problem is that the cocking piece has moved too far forward as the bolt is rotated to the down and locked position. That forward motion is controlled by the engagement of the cocking piece sear ramp and the sear boss.

Given that the new Jewell seems to work correctly but the previously working safety now doesn't, it would seem likely that we have the situation described in the last paragraph. Based on passed experience I would first check to see if the sear boss can get up through the sear clearance hole in the action floor. I've had to file corner clearance in the front (barrel) end of those holes so that the front edge is nearly square and full diameter of the hole (take care make sure to get clearance at the lower edge toward the trigger). After reinstalling the trigger, you will probably have to readjust the trigger for the greater sear travel.

If that does not correct the problem, the next likely culprit could be that too much material was removed from the front of the cocking piece sear ramp at final assembly fitting (this filling is done by factory fitter/assemblers for proper function to accommodate tolerance of the factory parts). Since you have replaced the factory sear the tolerance stack up is now different. The way to correct this problem would be to stone/file the cocking piece safety cam surface to restore the needed offset of that surface from the sear ramp for the safety cam to engage that surface.