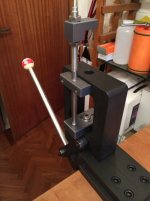

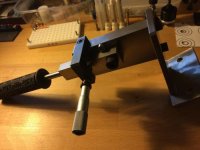

Hi ,my swage presses are the modified Redd. type and there are a good press to do the job but for core seating i would like to know if there's somthing better out there ,i see on the RCBS web site that they offer a special order swage press, does anyone have any info about the press they offer.

Thank's Remy

Thank's Remy