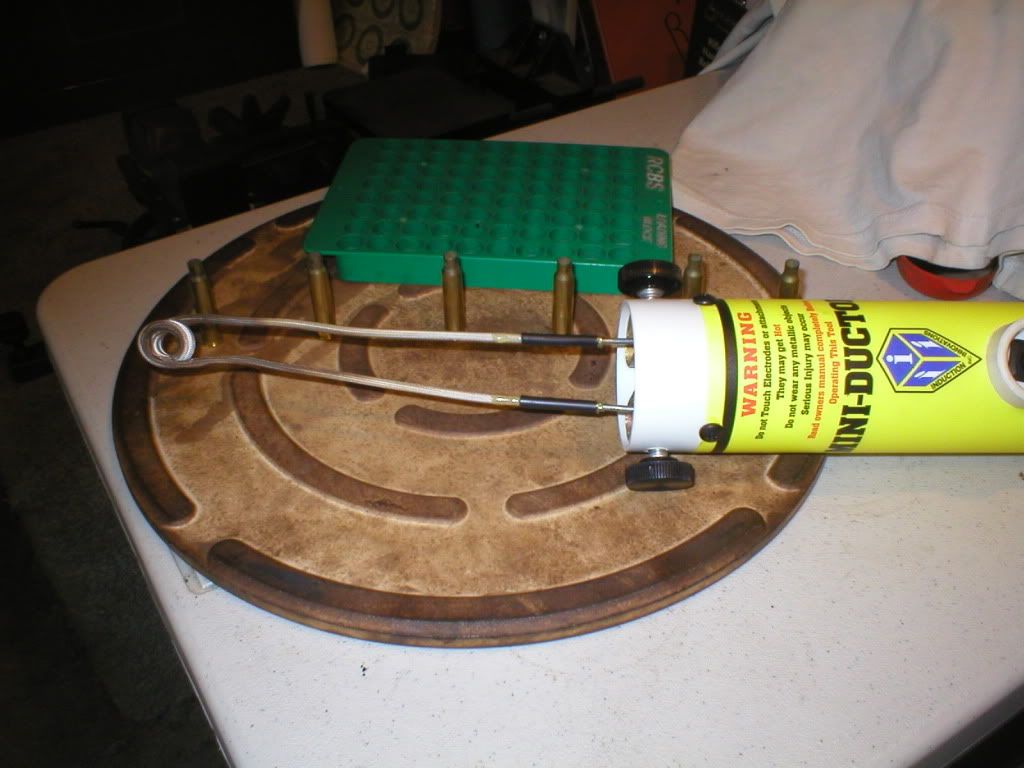

The machine seems to work best if I am annealing a neck that just barely fits inside the coils and I can get at least 2 coils on the neck. However, .223 rem cases do not fit that criteria and they anneal quite quickly. I think that may be the mass of metal in the case body issue again. The machine comes with one preformed coil which is way too big, one user formable coil, and a limp wire that I am told is for use on large bearings and such. I tried reforming the preformed coil to do .30 caliber necks, but I was afraid of breaking the wire so I only went so far as to be able to do .44 .45 cal handgun case mouths with it. I had to settle for one coil to do .30 and below. The sloppier clearance does no harm and does anneal the case, it's just slower, which brings the up undesirable issues we find in most flame annealing. At the time I bought my tool you could get more coils only in a kit which included a lot of stuff I did not want. Possibly you can buy single user formable coils now. I shoot mainly 6 and 30 BR these days and have a pretty good setup for doing those cases quickly, so I am not in a hurry to buy any new coils.