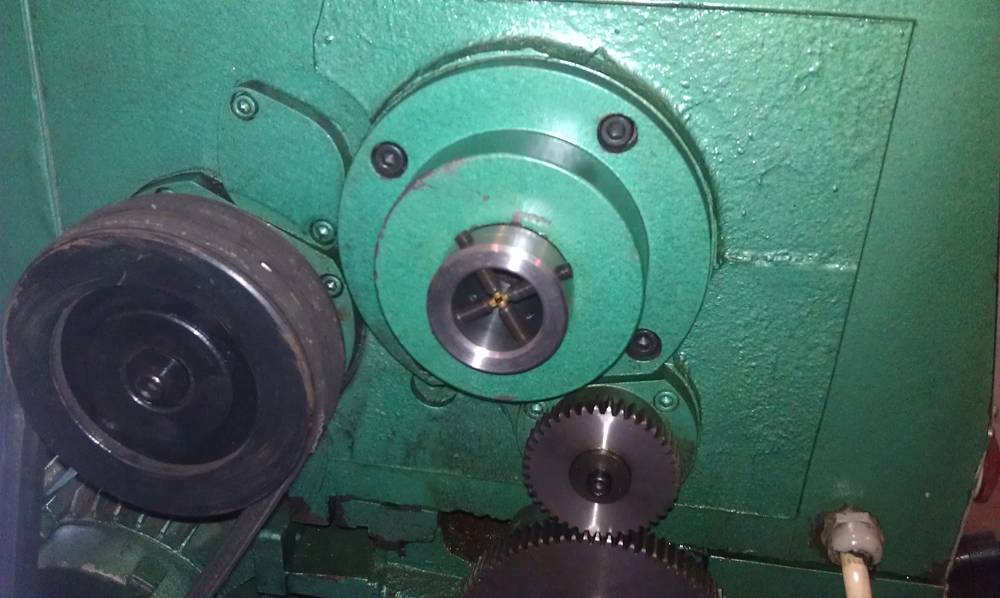

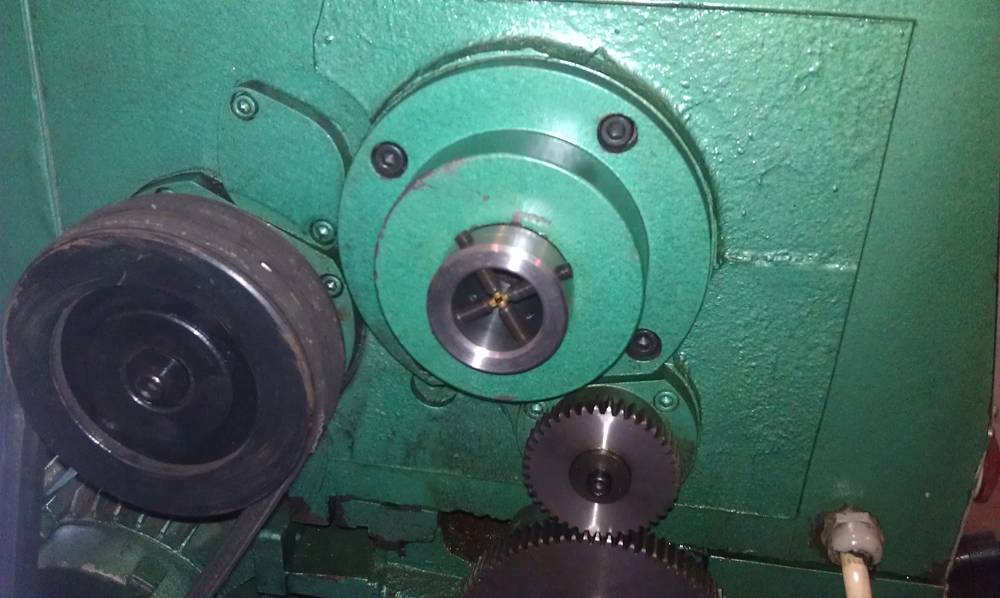

Finally finished my outboard spider and used it to dial in the muzzle end of a Krieger 4 groove 6mm barrel. I think I am on the right track. Is my muzzle dial acceptable?

Do you dial in the chamber end first, then dial the muzzle and then go back and forth till both ends are acceptable?

I may fabricate a front spider to dial in the chamber end...anyone dialing in using a front and rear spider? Will a front spider provide enough holding power?

Do you dial in the chamber end first, then dial the muzzle and then go back and forth till both ends are acceptable?

I may fabricate a front spider to dial in the chamber end...anyone dialing in using a front and rear spider? Will a front spider provide enough holding power?