Pete Wass

Well-known member

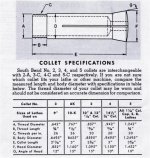

I am wondering what the numbers and letter designations for collets means. I have an old (1941) 10 L South Bend which has the hardware necessaryo to use collets. I loaned the collets to a gent who hs passed and my collets are no longer available. How do I tell if I have a 3-C or whatever setup?