Boyd Allen

Active member

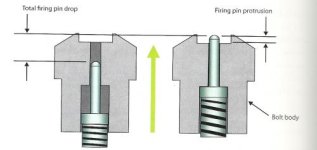

Let's try again. If you build a firing pin that was identical to the one that came in your bolt, except that the tip was so long that is was flush with the bolt face when the pin was cocked, you would have the same fall on an empty chamber, but in fact, for the purpose of setting off a loaded round, there would be very little net fall, and probably not enough energy to dent the primer significantly or set it off. Then let us trim off say .050 off of that tip. The net fall would increase by that amount, whereas the fall on an empty chamber would remain the same, because its stopping point continues to be contact between front of the shoulder of the the firing pin, and the inside of the bolt. We can progress with cutting off the tip of the pin, gaining net fall, until we reach the point where the front of the pin shoulder contacts the inside of the bolt, at which point we will have reached our limit, or more than likely gone past it, since I am sure that having the pin bottom in this way would create an undesirable vibration that one may guess would be detrimental to accuracy. Long and short of it, the trigger is not involved because the distance from the cocking piece to the front of the firing pin shoulder is not changed. Neither is the pin fall on an empty chamber. The protrusion is decreased in direct proportion to the shortening of the pin tip, but as long as it sticks out farther than a primer will allow it to, when firing, there should be not detrimental collision inside the bolt, and there should be a small amount of increase in energy delivered to the primer.