J

John Scope

Guest

Viper:

Cast bullet shooting, as others have mentioned, is a frustrating endeavor and is to be avoided by any rational person.

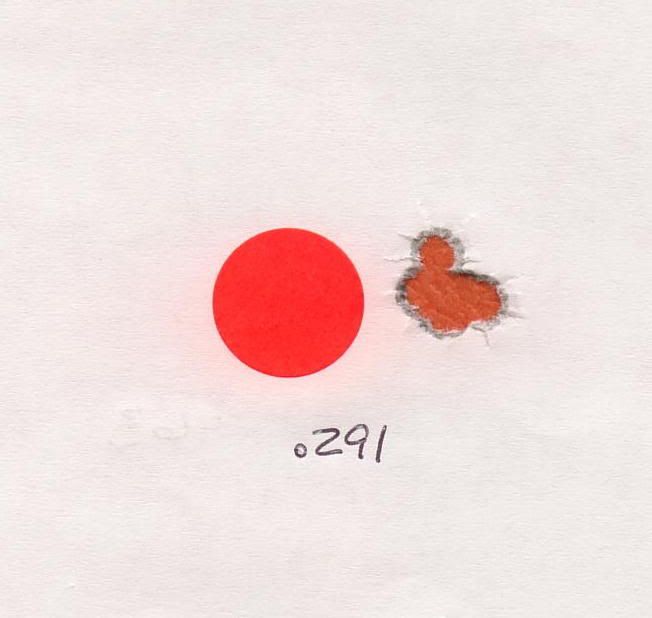

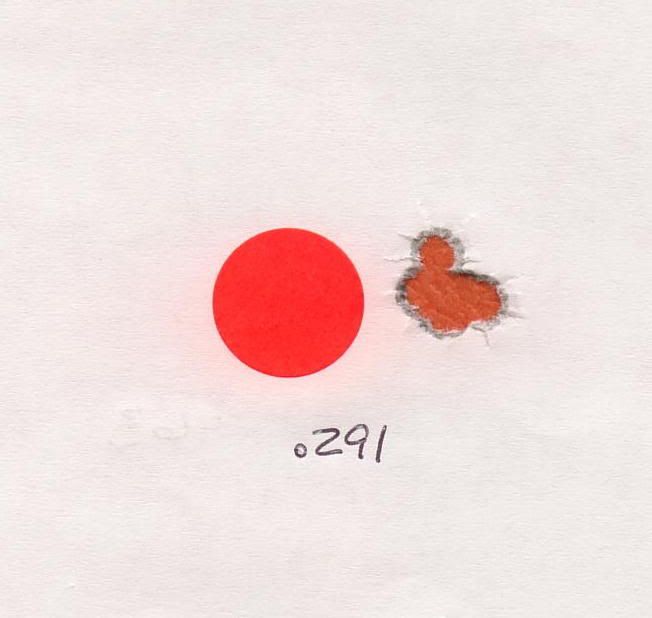

However, I have had some success with the .308 Win cartridge and cast bullets. In particular, a tight neck (.340") chamber, Lilja 1-10" barrel with a .299" bore mounted on a Borden built Teddy Heavy Varmint. Bullets were Lyman 311291 (modified) weighing 169 gr., sized .311" and moly coated. Load was 21.0 Rx 7. Lapua brass, of course.

John

Cast bullet shooting, as others have mentioned, is a frustrating endeavor and is to be avoided by any rational person.

However, I have had some success with the .308 Win cartridge and cast bullets. In particular, a tight neck (.340") chamber, Lilja 1-10" barrel with a .299" bore mounted on a Borden built Teddy Heavy Varmint. Bullets were Lyman 311291 (modified) weighing 169 gr., sized .311" and moly coated. Load was 21.0 Rx 7. Lapua brass, of course.

John