Stephen Perry

New member

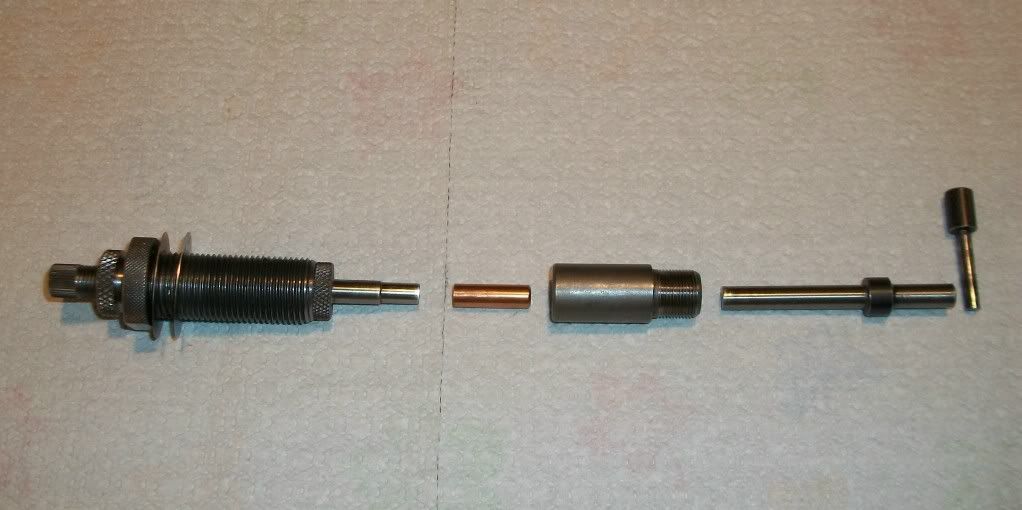

Bahler Bullet Dies

I have a set of Bahler 22 bullet making dies. Don't know much about them. I feel they were made back in the 1950's. Back then these could have been considered BR quality dies. Remember 22 bullet making was King for BR and Varmint shooting way before the 6x47 and the 6 PPC. I make a good amount of 22 cal bullets each year for my BR guns.

They were given to me by Allen Bench back in 2004. Allen said they were made by a guy in the NW and made good bullets. Allen had 8 sets of them, he'd got from estates and shooter friends. Allen had a set that he used to make 22 bullets. The die set is a steel 3 die set -- Core Making die, Core Seating die, and a Point-up die. Allen gave me 5 core seating punches to go with the dies. George do you know anything about the Bahler bullet making dies ?

Gerry I would like to get some Sierra 22 jackets to use in these dies, Allen said they work well with these dies. Do you know who sells the Sierra jackets Gerry or should I call Sierra. I plan on making bullets on these dies to shoot in my 22 cal factory rifles, any info would be of help.

Al thanks for the additional pics on your Blackmon dies. Do you make any other bullets besides 30 cal ?

Stephen Perry

Angeles BR

I have a set of Bahler 22 bullet making dies. Don't know much about them. I feel they were made back in the 1950's. Back then these could have been considered BR quality dies. Remember 22 bullet making was King for BR and Varmint shooting way before the 6x47 and the 6 PPC. I make a good amount of 22 cal bullets each year for my BR guns.

They were given to me by Allen Bench back in 2004. Allen said they were made by a guy in the NW and made good bullets. Allen had 8 sets of them, he'd got from estates and shooter friends. Allen had a set that he used to make 22 bullets. The die set is a steel 3 die set -- Core Making die, Core Seating die, and a Point-up die. Allen gave me 5 core seating punches to go with the dies. George do you know anything about the Bahler bullet making dies ?

Gerry I would like to get some Sierra 22 jackets to use in these dies, Allen said they work well with these dies. Do you know who sells the Sierra jackets Gerry or should I call Sierra. I plan on making bullets on these dies to shoot in my 22 cal factory rifles, any info would be of help.

Al thanks for the additional pics on your Blackmon dies. Do you make any other bullets besides 30 cal ?

Stephen Perry

Angeles BR

Last edited: