S

str8shooter

Guest

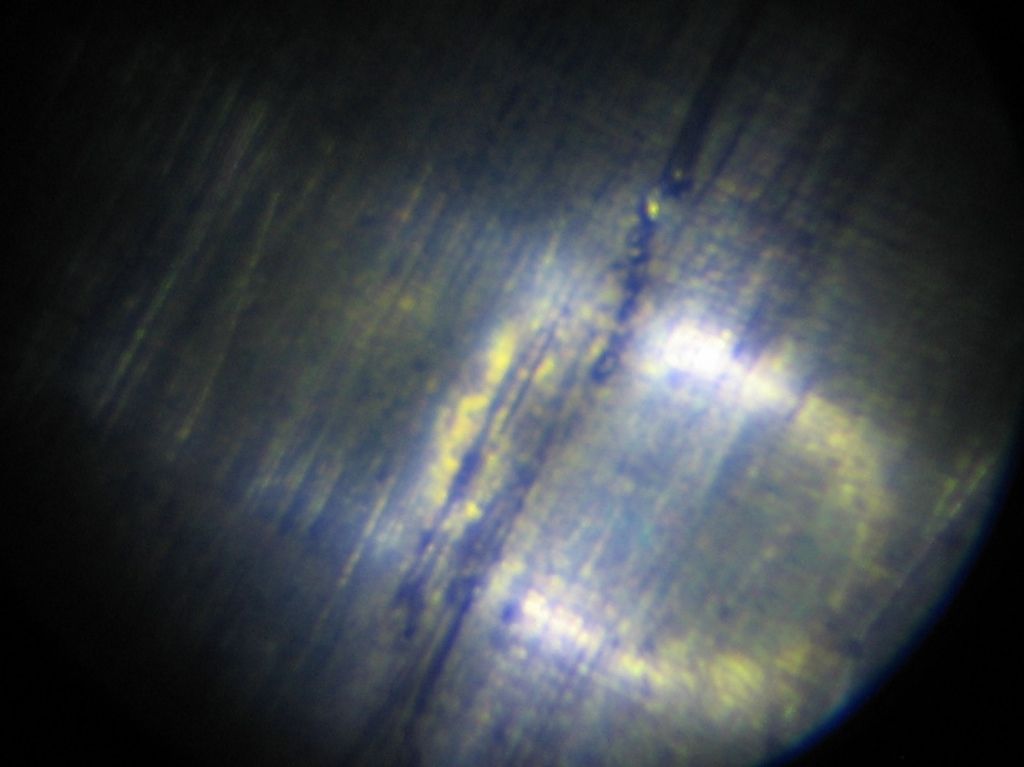

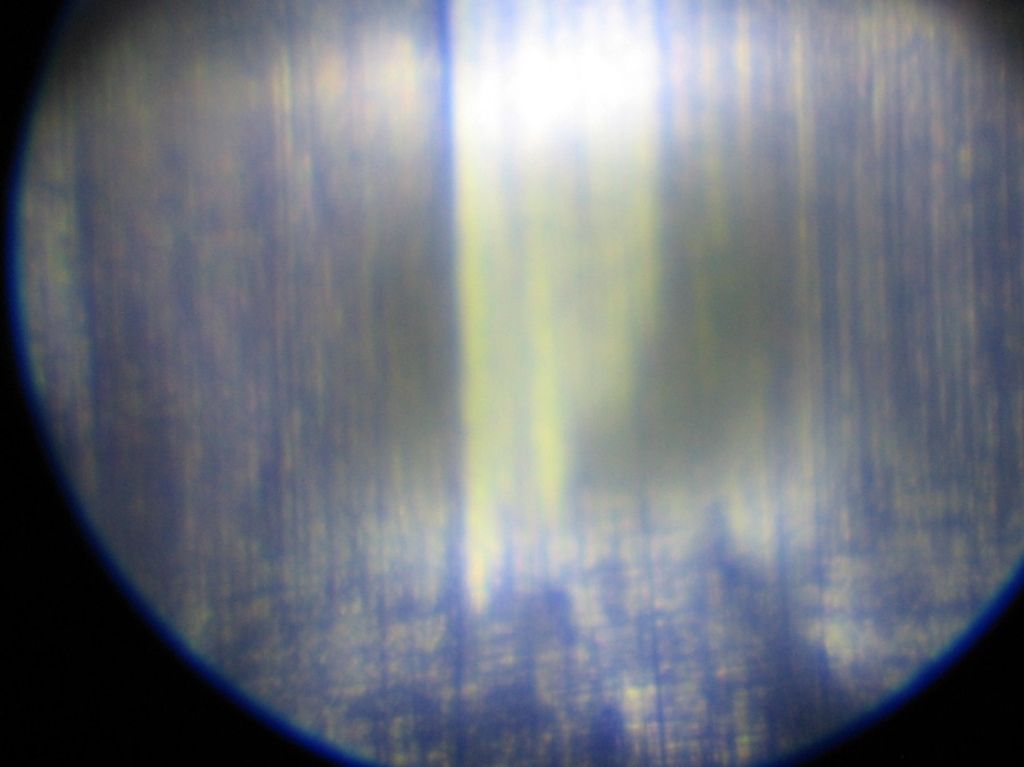

I had a 300 WM built in February. It has less than 100 rounds on it. I've been getting clicks at the top of extraction since the first shot and havn't been able to finish load development because of it. I've tried 3 types of brass (rws, win, norma) and get the same issue each time. My cases have a noticeable bulge about .002 bigger than the rest of the case for about .050 just ahead of the belt. After the first shot with new brass, the cases will not go back in the chamber the bolt close, they go in as far as the bulge then stick. It was borescoped and I was told there was a relief cut made for the belt that was radiused which caused the area just ahead of the belt to be unsupported causing the case bulge. It sounds like the barrel needs to be set back, my question is how much length will I lose on the barrel and can it be done without destroying the cerakote?