Perfectly straight barrels are a rare thing

Perfectly straight barrels are a rare thing… I haven’t seen one yet…

Airgun barrels typically aren’t made from the same (chrome-moly 4130/4140) steel that firearm barrels are typically made from. Some inexpensive barrels are made from tubing (Drawn Over Mandrel Tubing) and some from brass. Most quality airgun barrels are made from 1117 free machining steel; the same steel used in rimfire barrels. For quality barrels the steel used in the blanks must be supplied in the correct alloy and tested for consistency.

Most of the quality airgun barrels we use today are made using the “button” rifling process where a steel barrel blank is placed in a barrel drilling machine, a special “gun drill” bores an undersized hole in a steel barrel blank which is then reamed to smooth the bore and bring it to a desired size. This process creates the bore diameter of the barrel.

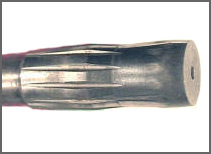

A tungsten carbide button is drawn (pulled) through the reamed hole in the barrel blank to create the rifling. The tungsten carbide rifling button is ground to the size and shape of the grooves and twist rate desired in the barrel. The button is a precision tool that is compensated in size for the steel barrel alloy it’s being used in and the lubrication used in the process. The rifling button creates the grooves in the reamed hole by displacing the metal; none is removed from the bore during the process. The rifling button may include an “ironing button” or another football shaped “smoothing” button may be drawn through the bore to make/draw the bore diameter to a finished size.

Rifling button with ironing button

During the button rifling barrel making process stresses are created and released. Many of the makers use heat treating cycles to normalize (relieve stresses) in the blanks. Anything we do to the barrel to induce or relieve stresses in the barrel such as machining will change the curvature of the barrel. Yes, you can bend the barrel to compensate for the curvature and many gun makers do exactly that; however, most barrels have some degree of curvature present.

What does indexing a barrel in the rifle’s receiver accomplish?

Indexing allows us to compensate for irregularities in the direction the barrel is shooting.

Every barrel will vibrate during the shooting process and the concept of indexing is to orient the existing curvature or a bore offset from center in a vertical plane to produce a “vertical only signature”. When the barrel is out of tune it will print groups with some degree of horizontal dispersion (horizontal stringing). It doesn’t matter if you use the 12 o’clock or 6 o’clock position… sometimes you may prefer one over the other, such as making as many clicks in your scope available as possible.

By rotating (indexing) the barrel in the receiver with the bore centered in the receiver the gun will shoot (print) groups in a circular pattern like this:

This 3 inch diameter pattern was shot from my TM1000 with the target at 25 yards.

Barrels or blanks used in guns with a side ported barrel will require a thimble with the transfer port fitted to the barrel to permit indexing and barrels will require preparation for thimble installation:

This bore was offset 0.008” in the barrel blank at the receiver end requiring the barrel to be turned down to run true to the bore and a sleeve installed on the shank to fit the receiver prior to installing the thimble.

I use a dial indicator and a set of plus and minus ZZ gage pins in half thou steps to center the barrel in a run-true collet or six jaw chuck in the lathe to setup the barrel with a total indicated runout (TIR) of 0.0005” (half a thousandth) or less at the chuck and a thousandth or less TIR at the outboard side of the headstock (muzzle). If the blank or barrel can't be machined to fit the receiver with the bore centered I cut down and sleeve the blank or barrel to run with the bore centered in the action/thimble

I use o-rings on my thimbles and improved breach seals for improved consistency and lower extreme spreads.

The barrel or blank must have a good crown and the bore must run true with the thimble and receiver.

The crown is cut from the inside-out with razor sharp hand honed carbide tooling. I prefer a recessed crown of the stepped or 11 degree styles.

Have Fun

Boomer