adamsgt

Jerry Adams

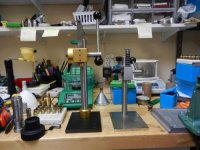

With all the recent thrashing around about bullet seating, I decided to look into upgrading my arbor press. Looked at a few and decided to get a Hart. The pictures on their web site weren't all that impressive so I was hoping it would be worth almost double the price of a Sinclair arbor press.

Well, here they are side-by-side. In case you can't figure it out, the Hart is the one on the left. I think I'll keep it. Don't know if I'll take it to matches, but it's definitely got a place on my bench. I'll make the room.

Well, here they are side-by-side. In case you can't figure it out, the Hart is the one on the left. I think I'll keep it. Don't know if I'll take it to matches, but it's definitely got a place on my bench. I'll make the room.

Attachments

Last edited: