Butch Lambert

Active member

Jay,

Send me a PM.

Send me a PM.

They are identical.

Good thing for cutting V at a perfect 90° is you can buy some aluminum angel iron and lay in the v blocks. Stack a few angel irons in the V on the tapered end of yer barrel and square up the end you want engraved. Light and heavy varmints and straight cylinder barrels I just clamp em tight and engrave them.

I can clamp dies and engrave them before I send them to heat treat. I have a die to work on I'll try to post a pic of that setup soon if ya want to see it.

My new hermes seems to make the nicest letters with one trace. Going back over the letters seems to dull the lines. Also let the tool cut- dont put too much down pressure on it. Once i learned all that my letters look so much better. I have 3 sets of fonts that wont fit in my double slot i need to sell if somebody wants to try them in theirs. They come in a wood box. Not hermes brand but nicer. Dont know what they fit but they should work in a homemade pantograph. They are so close to fitting ive always hated to get rid of em

Looks good.Looks good Jay!

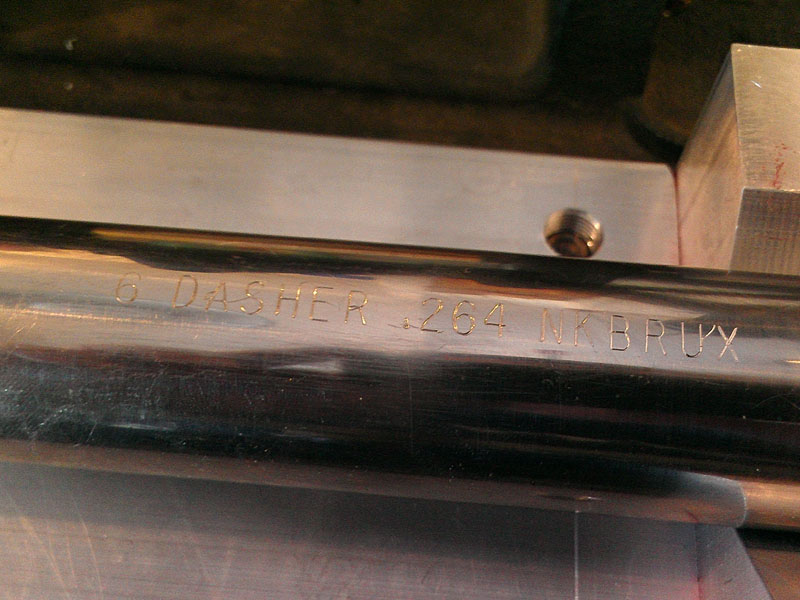

Speaking of font, I just picked up a full master copy set of single line scrip with upper/lower case, numerals, punctuation, special characters and a bunch of spacers. The scrips looks very nice on barrels and stuff! Here is a stub I did.

How many passes are you guys using when you engrave? And how deep are you setting the cutter? I've been doing two passes with the cutter set progressively deeper. It comes out nice, but in two line fonts, it's not as nice as I would like.

Jaychris....you using a rotary or drag type cutter?

I am just using a 130 degree diamond tipped drag and I make 2 passes with downward pressure on the drag. Being a 130 degree drag, depth go only so far. I'd imagine to go deeper, 120 or a 90 degree drag might be in order, but may compromise or put more stress on the actual diamont tip and cause it to to chip or break. I do want to try a 120 and see how it works. I'd like a tad bit deeper engrave.

The stub done above is two passes.

I can see how a double line font might be tricky to engrave with, especially on a cylindrical objects.