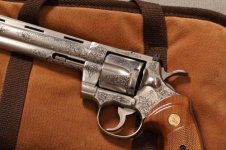

I can't help but wonder what could be done with laying down ground work with a laser and then going old fashioned engraving over top to bring it all together.

Then again some of the extras put into benchrest tools kind of worries me.

When you remove metal you relieve stress and change the shape of the metal that is left behind. I'll try and give an example.

While machining large disk if you watch your work this is something you might see. I used to make something called a valve but what it was, was a large disk like a coin. The first steps were to skim the outside and the two faces. This material was cut out of a large plate with something like a cutting torch or plasma cutter. Anyway the faces were cast and very rough. Skimming these surfaces removed a layer of very stressed material.

Even after it was removed, or in any blank of metal, stresses remain pulling on each other.

After cleaning up the blank of the crusted material I could face down the face, or like the flat side of a coin, and check it and it would be pretty flat.

The next step would be to face the other side and try and get a little closer to the finished thickness.

Now if I would go back and check the previous side that was once flat, it no longer is. Two of the opposite edges would now be bent down and the other two bent up. Just like a potato chip.

I think the material I just took off also had stresses in it pulling on it making it want to be in the shape of a potato chip. They were just pulling in the opposite direction allowing the first side to be flat. Once it was removed the flat side warped.

Anyway that is the way it goes facing large disk. You have to keep flipping them back and forth until you are just removing a minimal about as to keep the other side from taking the shape of a potato chip.

That leads me to sort of freak out when I see some work like barrel fluting. If it is for weight and carefully done I suppose it could be worth the risk. If some of it to just be fancy may be giving up to much ground to functionality.

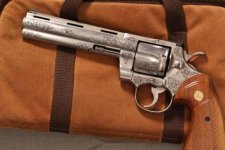

Some work can look nice though.