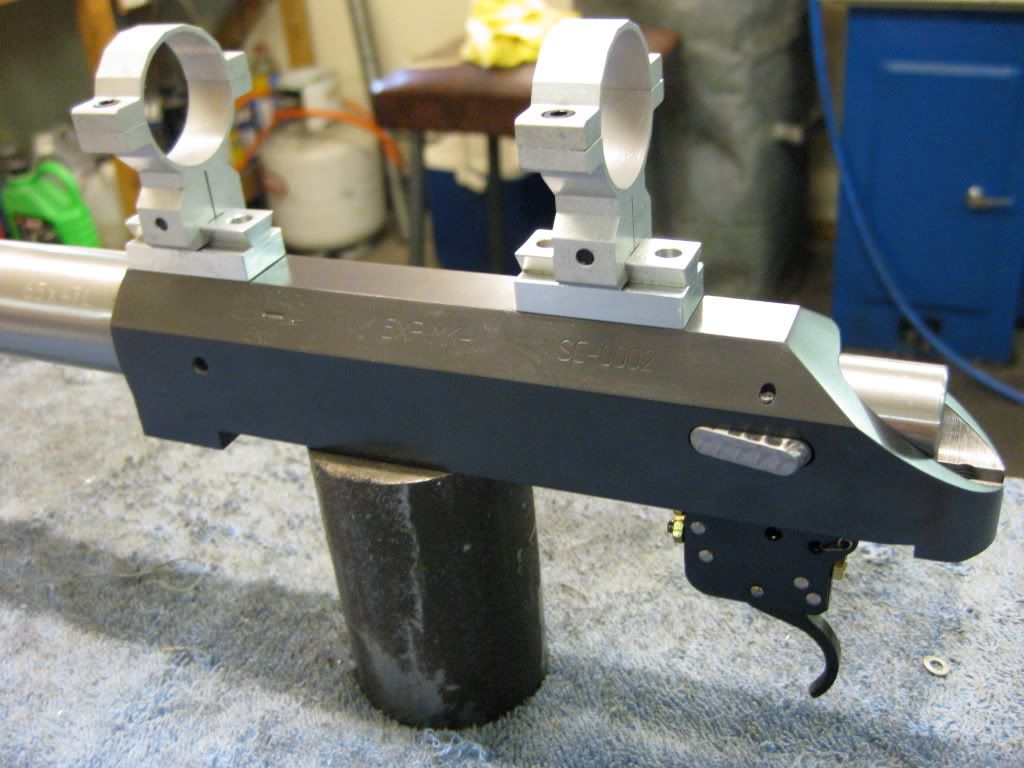

Some test firing

G'day Guys.

Well an oppertunity presented its self today to test fire my action.. I had decided to chamber up an old 6mm Barrel for the testing in 6x47 Lapua. Load data for this cart is a bit thin on the ground but i had some data from a "Gun of the week" on 6mmBR.com. A good mate had worked up the same loads in one of his rifles and they were about spot on. The loads listed were with Varget and some 70Gn bullets. Starting at 35.5 Gns to 40 Gns max. My mate had worked up the same loads using AR2208 (Equal to Varget) and got the same result, with 40 being max in his rifle.

So i loaded up;

1 @ 35 Gns

1 @ 40 gns

1 @ 41 Gns

1 @ 42 Gns (Compressed load)

I would have gone one grain more but 43 gns of 2208 just wouldn't fit the the case even with a drop tube..

I havn't got a stock yet so i lugged my large machine vice (25Kg's) to the firing point and clamped the barrelled action in the vice. Round was loaded and a towl followd by two sandbags were placed on top of the action. Fireing was done remotely with a 4 meter length of string.

Started with the 35 Gn load and well, it was all very anti-climactic as it went bang and the action did not fly apart. :boogie: :boogie:

Bolt lift was smooth and primary extraction was easy.

The same was repeated with the other three rounds all showing easy bolt lift and easy extraction.

All cases show no pressure signs at all except the last round which shows just a slight cratering but realy nothing at all to worrie about. Considering that the last round was 5% over the sudgested max i am very pleased with it.

Headspace was checked before and after firing all 4 rounds and as expected hasn't changed one micron. I am now totaly confident in the actions strength to handle even the largest cal in 308 boltface.

35 Gns on the far left and 42 Gns on the far right.

Cheers

Leeroy