jackie schmidt

New member

While laying in bed the other night, I was thinking about the various methods of mounting a Barreled Action to the top of a Rail Gun Top. Barrel Blocks are the most successful it seems. And they work once you arrive at the proper tension of the clamping screws.

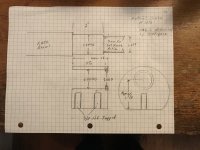

For some reason, recoil lugs popped up in my head. I see thick ones on big rifles, so what if you incorporated a stress free way to mount the barreled action with a precision machined mounting block that was in reality a huge recoil lug.

This is what I came up with. The block is machined from 17-4 PH at H 1050. It was bored and faced on the same setup to insure it is dead square. The barrel is machined to match it. The fits have .001 clearance in the bores of the block.

The block is secured with two 3/8 24 bolts

I’m going to try this,.....just because.

http://benchrest.com/attachment.php?attachmentid=23693&stc=1&d=1592528120

http://benchrest.com/attachment.php?attachmentid=23694&stc=1&d=1592528163

http://benchrest.com/attachment.php?attachmentid=23695&stc=1&d=1592528226

http://benchrest.com/attachment.php?attachmentid=23696&stc=1&d=1592528279

http://benchrest.com/attachment.php?attachmentid=23697&stc=1&d=1592528380

For some reason, recoil lugs popped up in my head. I see thick ones on big rifles, so what if you incorporated a stress free way to mount the barreled action with a precision machined mounting block that was in reality a huge recoil lug.

This is what I came up with. The block is machined from 17-4 PH at H 1050. It was bored and faced on the same setup to insure it is dead square. The barrel is machined to match it. The fits have .001 clearance in the bores of the block.

The block is secured with two 3/8 24 bolts

I’m going to try this,.....just because.

http://benchrest.com/attachment.php?attachmentid=23693&stc=1&d=1592528120

http://benchrest.com/attachment.php?attachmentid=23694&stc=1&d=1592528163

http://benchrest.com/attachment.php?attachmentid=23695&stc=1&d=1592528226

http://benchrest.com/attachment.php?attachmentid=23696&stc=1&d=1592528279

http://benchrest.com/attachment.php?attachmentid=23697&stc=1&d=1592528380

Attachments

-

70F97680-1079-4B16-92BA-3BBBF878F821.jpeg2.8 MB · Views: 1,002

70F97680-1079-4B16-92BA-3BBBF878F821.jpeg2.8 MB · Views: 1,002 -

8D7450BB-F053-44ED-A963-00231B00C770.jpeg2.1 MB · Views: 820

8D7450BB-F053-44ED-A963-00231B00C770.jpeg2.1 MB · Views: 820 -

031DA9D5-1377-4466-AD14-93E031163DD1.jpeg2.2 MB · Views: 824

031DA9D5-1377-4466-AD14-93E031163DD1.jpeg2.2 MB · Views: 824 -

D5B6EDE2-1A68-42AF-AC55-096A07B9ED17.jpeg2.6 MB · Views: 769

D5B6EDE2-1A68-42AF-AC55-096A07B9ED17.jpeg2.6 MB · Views: 769 -

94EB2740-5762-4207-9668-057FEC2E6B09.jpeg2.5 MB · Views: 803

94EB2740-5762-4207-9668-057FEC2E6B09.jpeg2.5 MB · Views: 803