Almost done!

I mean just almost.

This is the stock, with epoxy filler applied...After this, will be sanded again, paint it black (as a base color) then apply "chameleon" paint, then clear coats & polishing.

I only use the wood model shown in the old pics above (from "kapok" wood), put some fiberglass & resin. (just a wrap around thin layer to make weight). I only make a new "bottom part?" to be paralel with the fore arm. A lot of work & time consuming....I wouldn't have enough time to make a new one (identical) from balsa wood & carbon fiber just to make the stock to weigh about 22 oz or less.

This stock weighs approximately 24 oz now. (the "main stock" is about 20.5 oz, the "bottom part" of the butt stock is about 3.5 oz). It should be no more than 27 oz, finished. It's still under the max weight limit (29 oz) Jim told me before....(action 30 oz, barrel 82 oz at 22", trigger/hanger/guard 4.5 oz, scope & rings 23 oz, stock 27 oz max --- total weight would still be under 168 oz/10.5 lbs, including mirage shield). No fancy alumunium butt plate.

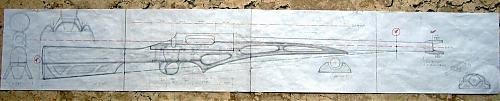

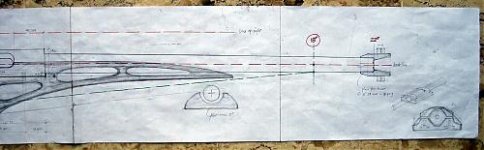

The taper of the butt stock...

It would "intersect" the center line of bore at 17" to 18" max. (would depend on the angle when glueing the action).

Although it is not a perfect method, if you put a straight ruler (or just a piece of paper) on your monitor, you would see the buttstock's angle would intersect the barrel just behind the black O ring (at 18" from the bolt face).

According to some inputs before, the angle would/should be okay, or still meet the rules. Anyway it is easy to adjust the angle of the toe since the "bottom part" is a knock down part (for instance using a shim or spacer). I use two small screws (with alumunium pillars inside) to attach the bottom part to the stock. I can also easily change the bottom part with another one, for instance with a normal 3/8" or 1/2" flat.

The "bottom part" shown in the pic is about 75mm wide (almost 3"), just about the same with the fore arm. They are paralel/inline, of course. The stock is more stable on bag with the extra wide bottom part, compared to bottom part with 1/2" flat that I also make. (I make some "bottom part" here). This is interesting, and just as like my prediction before. I just used two 3" front bags to slide the stock, btw. (one in front, one at the back). However I will make a rear bag (with 3" spacing) to suit the buttstock though.

Hopefully the complete rifle would track okay/straight, too!??

The "point of balance" of the stock (without weight under the butt) is around the bolt handle recess.

From LV to HV, I will make a weight just under the bottom part. (with s/s, fits to the "space" under the bottom part, the weight would be about 3 lbs or a bit less). The construction is strong enough to resist shock/recoils, I believe.

The stock is stable and also strong enough to resist my weight (72 kgs). It flex a bit, though.

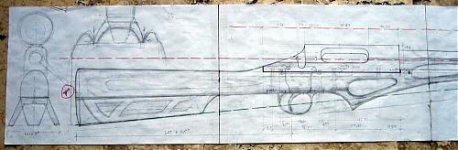

The inletting...(it's still rough).

Since I do not have a Panda action overhere, I only make the inletting from the data/drawing I got from Kelbly before. I only hope it would fit okay. I still will add a layer of steel epoxy glue (skim bed) around the inletting and shape/sand it so there will be a little clearance for glue in.

The black plastics are just for "footprint" purpose. I used them to help me when I put the pillar beddings & shaping the tang area & bolt handle recess.

*The (3) pillar bedding is for "just in case thing". My previous "thought" is, if the rifle shoots okay using screw in method, I might glue in the action then...however I wouldn't have much time in Ohio from May 18 to 20, so I will leave this matter to Kelbly. I am sure they know the best thing to do once I send the stock. It should be much better they do the glue in/installation before my arrival!

I need inputs here...............as many peoples say, "you would never know until you try"....but in your opinion, would this stock okay, looking from my (poor) description & pics above???

IF you think this stock would be just okay(?), I would not make another/second stock anymore. (my previous thought is, to make a second stock from local exotic wood with some carbon fiber in "normal" shape).

TIA,

seb.