You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

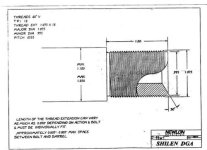

Need Shilen DGS Action barrel tenon specs

- Thread starter eggman

- Start date

Attachments

Last edited:

This answer was given a while back to the same question.

"DGA with a flat bolt nose. Receiver face to front of bolt = 0.750 inches so the tenon length should be 0.742 - 0.745 inches if you wanted a snug clearance or 0.740 inches if you wanted a bit more, that is without a recoil lug. The Shilen recoil lug that came with that action has a thickness of 0.2408 inches so if you were using a Remington style of lug you would have to increase the length of the tenon by the measured lug thickness.

DGA with a coned bolt nose. Tenon length = 0.865 inches, with no recoil lug. My coned bolt DGA's were PPC BR rifles and glued in so did not use a recoil lug but if you were using conventional bedding and a recoil lug you would again need to make the appropriate allowance for it on the tenon length. Remember also that if you are doing a barrel for a DGA with a coned bolt nose that the bolt nose angle is 25° per side not the 30° per side that you are used to doing for a Panda."

"DGA with a flat bolt nose. Receiver face to front of bolt = 0.750 inches so the tenon length should be 0.742 - 0.745 inches if you wanted a snug clearance or 0.740 inches if you wanted a bit more, that is without a recoil lug. The Shilen recoil lug that came with that action has a thickness of 0.2408 inches so if you were using a Remington style of lug you would have to increase the length of the tenon by the measured lug thickness.

DGA with a coned bolt nose. Tenon length = 0.865 inches, with no recoil lug. My coned bolt DGA's were PPC BR rifles and glued in so did not use a recoil lug but if you were using conventional bedding and a recoil lug you would again need to make the appropriate allowance for it on the tenon length. Remember also that if you are doing a barrel for a DGA with a coned bolt nose that the bolt nose angle is 25° per side not the 30° per side that you are used to doing for a Panda."

Al,

That's just being careful. Even the BAT Machine co. Inc. drawings from Newlon have the disclaimer "WARNING: BAT Machine Co. Inc. upon request builds special and oddbal actions with dimensions that vary from this drawing and does not accept any liability from the use or misuse of this information. All actions should be "measured individually" ." LOL

Merry Christmas All ,

Rodney

That's just being careful. Even the BAT Machine co. Inc. drawings from Newlon have the disclaimer "WARNING: BAT Machine Co. Inc. upon request builds special and oddbal actions with dimensions that vary from this drawing and does not accept any liability from the use or misuse of this information. All actions should be "measured individually" ." LOL

Merry Christmas All ,

Rodney

Mike Bryant

Active member

The best thing to do on any action is to use a pitch gage to determine the thread pitch and a depth mike to determine the bolt face to receiver face depth and the depth that the tenon needs to be cut depending upon how the bolt fits to the barrel, ie. coned bolt, counterbore, flat. Any measurements you need to make the tenon, you can get from the action. You can use a dial caliper or digital caliper to determine the thread diameter. I was looking at the Newlon print for the Shilen DGA and was surprised that the tenon diameter is listed at 1.075" as that isn't a standard thread, but they may have been where the castings cleaned up when they were cutting the receiver threads. But, you can also get the major diameter from the minor diameter measurement for the pitch of thread of the receiver with a little help from a Machinist's handbook.