You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

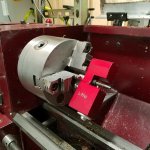

Neck Turning Tool for Lathe Mounting

- Thread starter parshal

- Start date

Mike Bryant

Active member

https://m.youtube.com/watch?v=IjEHQCjG6Yk

Take a look at this one. I chuck a Pumkin neck turner in a 6 jaw chuck indicate in the mandrel and push the case onto the mandrel holding it in a floating Sinclair case holder. It takes a little less than an hour to turn a box of brass.

Take a look at this one. I chuck a Pumkin neck turner in a 6 jaw chuck indicate in the mandrel and push the case onto the mandrel holding it in a floating Sinclair case holder. It takes a little less than an hour to turn a box of brass.

That would work but my PMA turners don't have the mandrel sticking out the back. Now that you say that, though, I seem to remember PMA had something that would mount their turner into something round that could be chucked. Maybe I'm remembering wrong but it does give me the idea to make one.

Mike Bryant

Active member

It’s also hard on your lathe switch. I didn’t come up with it on my own but had heard that was how Ron Hoehn was turning brass when he was alive. The way I’m doing it, the lathe spindle is never turned off until you’re finished. It takes me about 45 minutes to neck turn 100 necked up .220 Russian cases.That's one of the things I was thinking about. But, stopping/starting the lathe every time to get the brass out of the holder seems like it would get old.

Using one of the C type turners and chucking on a mandrel sticking out the back of the turner makes for a dangerous situation with the turner sticking out in front of the lathe chuck. The Pumkin is tailor made for using in the lathe. The Pumkin gets its fine adjustment from the minor diameter of the mandrel being .0025” eccentric from the .375” base of the mandrel. It wouldn’t be anything to make a round neck turner that can be chucked up in the lathe especially if you didn’t care to have the fine adjustment dial of the Pumkin. Once it’s set to depth, I don’t readjust it anyway.

NezRongero

Member

I'll play. 21st Century turning tool mounted in the chuck. The tailstock is driven to the chuck with a rack mounted on the bed. The handwheel runs the system fairly fast. All mandrels are Melonited, they just get shinier with use.

Video is just a demo for a friend, don't really wear long sleeves, though the belt is set up on loose side to slip.

Watch "21st Century Neck Turner" on YouTube

https://youtu.be/bGV4bfitGKA

Video is just a demo for a friend, don't really wear long sleeves, though the belt is set up on loose side to slip.

Watch "21st Century Neck Turner" on YouTube

https://youtu.be/bGV4bfitGKA

Attachments

Last edited:

as a part time machinist...i aint worried about wearing anything out.

retired means time available to do such things as turning necks.

working brass is so much fun i just processed 1200 308 win cases....dillon 550 makes things easy

fl sized, trimmed to length and then neck sized after expanding.

retired means time available to do such things as turning necks.

working brass is so much fun i just processed 1200 308 win cases....dillon 550 makes things easy

fl sized, trimmed to length and then neck sized after expanding.

It’s also hard on your lathe switch. I didn’t come up with it on my own but had heard that was how Ron Hoehn was turning brass when he was alive. The way I’m doing it, the lathe spindle is never turned off until you’re finished. It takes me about 45 minutes to neck turn 100 necked up .220 Russian cases.

Using one of the C type turners and chucking on a mandrel sticking out the back of the turner makes for a dangerous situation with the turner sticking out in front of the lathe chuck. The Pumkin is tailor made for using in the lathe. The Pumkin gets its fine adjustment from the minor diameter of the mandrel being .0025” eccentric from the .375” base of the mandrel. It wouldn’t be anything to make a round neck turner that can be chucked up in the lathe especially if you didn’t care to have the fine adjustment dial of the Pumkin. Once it’s set to depth, I don’t readjust it anyway.

Mike Bryant

Active member

I'll play. 21st Century turning tool mounted in the chuck. The tailstock is driven to the chuck with a rack mounted on the bed. The handwheel runs the system fairly fast. All mandrels are Melonited, they just get shinier with use.

Video is just a demo for a friend, don't really wear long sleeves, though the belt is set up on loose side to slip.

Watch "21st Century Neck Turner" on YouTube

https://youtu.be/bGV4bfitGKA

Nez, running it in with the carriage is pretty slick. It looks quicker than using the tail stock and gets your hands away from the chuck when changing out pieces of brass.

johan teughels

Member

i got a pumpkin also but also a old style neckturning tool and for that one i use thise method: put a drill holder in the tail stock then clamp the mandril from the turner in the drillholder

and so it is centered and you can clamp it in a 3 jaw clamp (i had to cut offa little bit from the top of the tool to make it fit when closing the jaws )

before i clamped the case holder in the 3 jaw and hold the neckturner in my hand but then you have to stop the lathe to change brass

and so it is centered and you can clamp it in a 3 jaw clamp (i had to cut offa little bit from the top of the tool to make it fit when closing the jaws )

before i clamped the case holder in the 3 jaw and hold the neckturner in my hand but then you have to stop the lathe to change brass

Pat Miles

New member

Another video turning necks on a manual lathe.

Gent shows a slick coupler to remove turned brass from the mandrel in the chuck.

https://www.youtube.com/watch?v=haTunbUJkjo&feature=emb_rel_end

Gent shows a slick coupler to remove turned brass from the mandrel in the chuck.

https://www.youtube.com/watch?v=haTunbUJkjo&feature=emb_rel_end

CYanchycki

Club Coordinator

Well if you contact

Bill from the video you never know....

He may be interested in making one for you.....

Calvin

That is slick! I don't turn enough necks to build a fixture like that. But, if someone here wants to make and sell one.....

Bill from the video you never know....

He may be interested in making one for you.....

Calvin

Pat Miles

New member

That is slick! I don't turn enough necks to build a fixture like that. But, if someone here wants to make and sell one.....

Don't get to enamored with his fancy fixture, just turn the brass using the technique up to 3:34 using the tailstock to insert and remove the brass from the mandrel. You can make the insertion/removal spud that he made for the fancy fixture but put them in a drill chuck in your tailstock.

GeneT

Active member

Impatient with videos?

Skip right to 8:11 and you won't have missed anything.

GsT

Gent shows a slick coupler to remove turned brass from the mandrel in the chuck.

https://www.youtube.com/watch?v=haTunbUJkjo&feature=emb_rel_end

Skip right to 8:11 and you won't have missed anything.

GsT